Large-scale organic matter refuse treatment classifying device

A technology of garbage disposal and classification device, applied in grain processing, conveyor, solid separation, etc., can solve difficult research and development breakthrough test and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

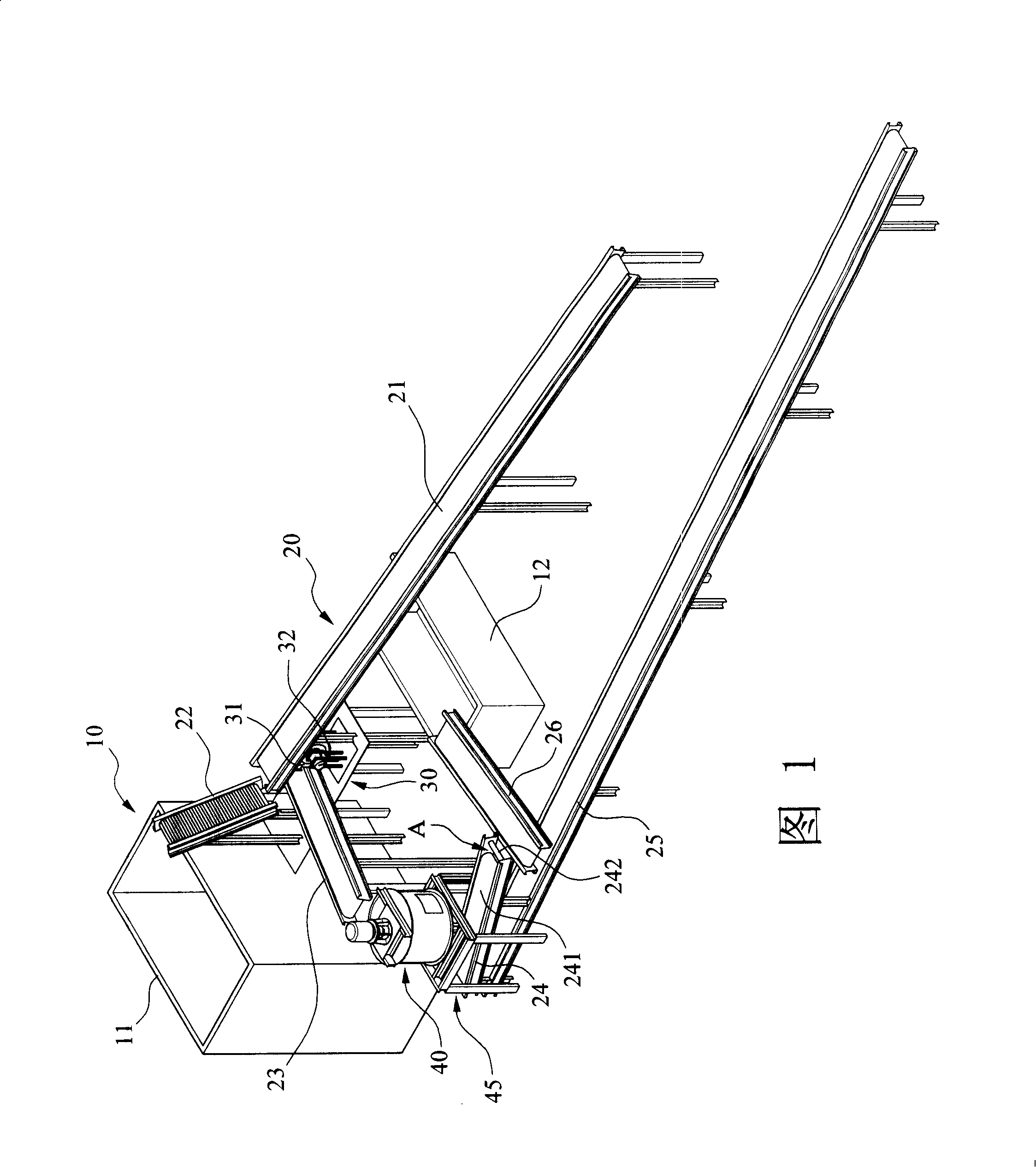

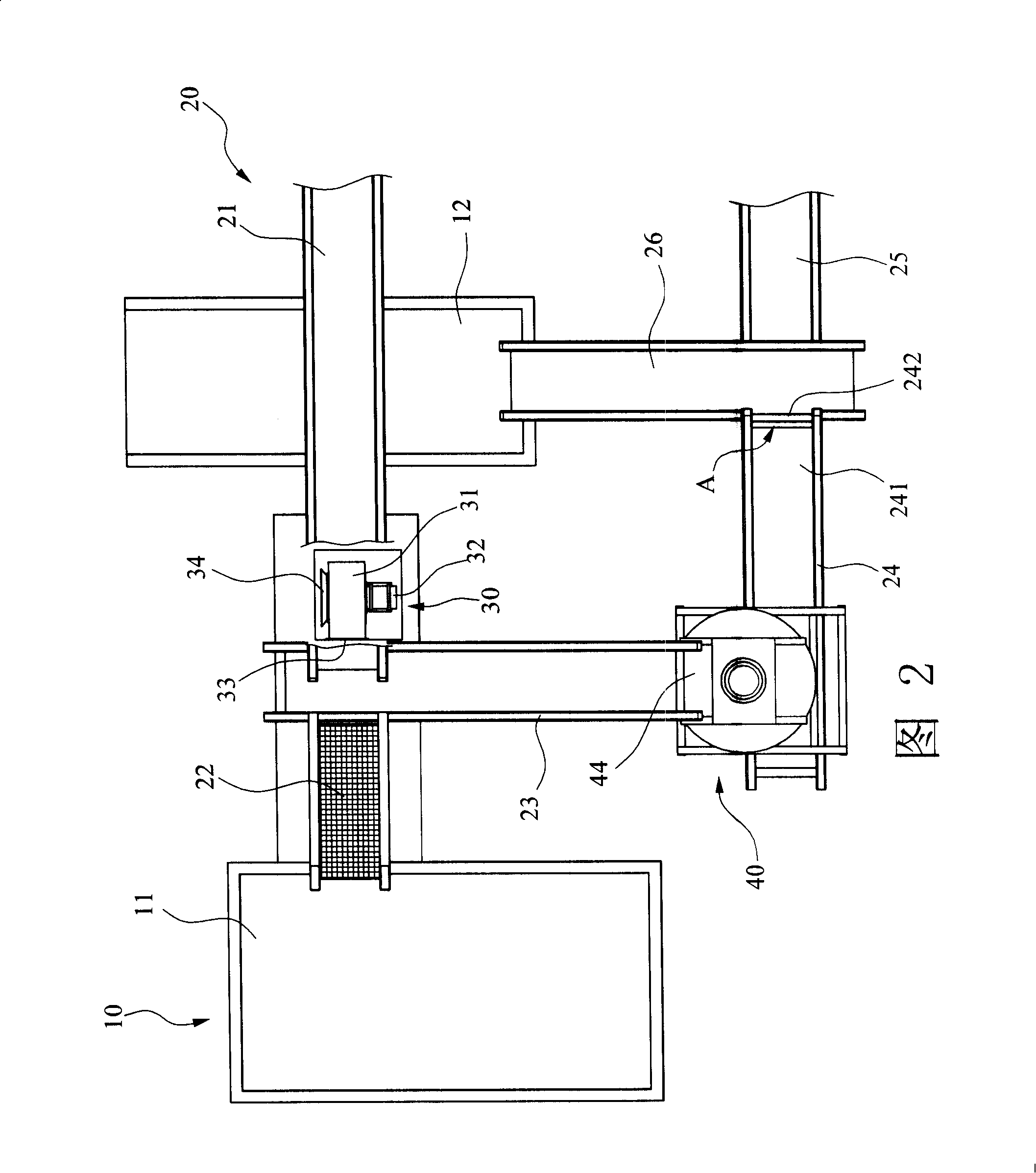

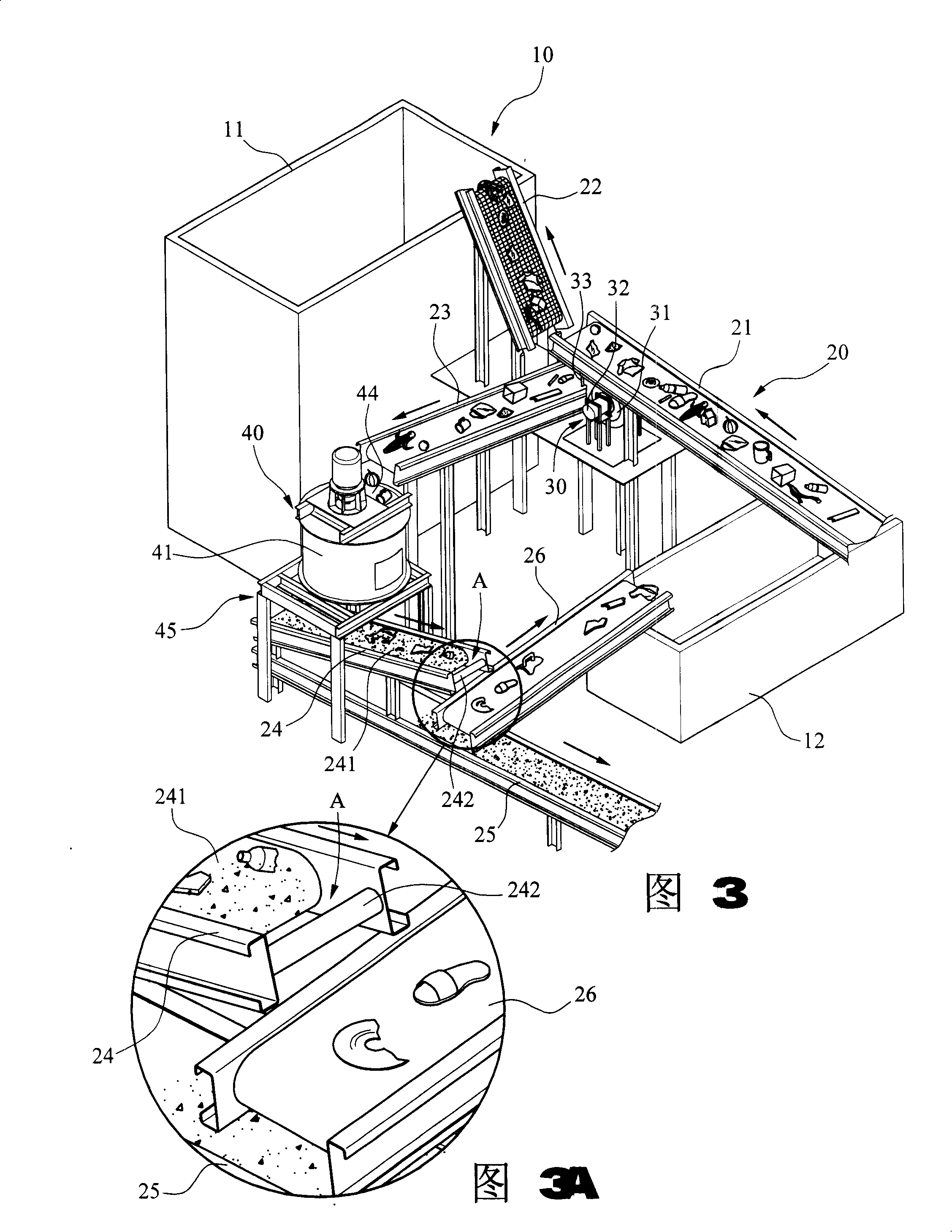

[0046]Please refer to shown in Fig. 1 to Fig. 3, the large-scale organic waste processing and classifying device of the present invention mainly comprises: a header device 10, conveying device 20, air supply device 30 and crushing device 40; This header device 10 includes a first collector Box 11 and the second collection box 12, the first collection box 11 is used to collect lighter garbage, and the second collection box 12 is used to collect larger and heavier garbage (detailed later). The conveying device 20 is driven by power (such as a motor) to operate as a transportation channel in garbage disposal, and it includes a mixed garbage conveyor belt 21, a light garbage conveyor belt 22, a heavy garbage conveyor belt 23, and a crushed garbage conveyor belt 24. , organic waste conveyor belt 25 and non-organic waste conveyor belt 26; the transmission end of the mixed garbage conveyor belt 21 is connected to the light garbage conveyor belt 22 and the heavy garbage conveyor belt 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com