Method using charcoal for promoting anaerobic digestion of sludge to produce methane

A technology for anaerobic digestion and methane production, applied in the field of solid waste recycling, can solve problems such as limiting large-scale application, increasing difficulty, corrosion of instruments and equipment, etc., to improve soil physical and chemical properties, increase anaerobic digestion effect, and produce methane. The effect of increasing the amount of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

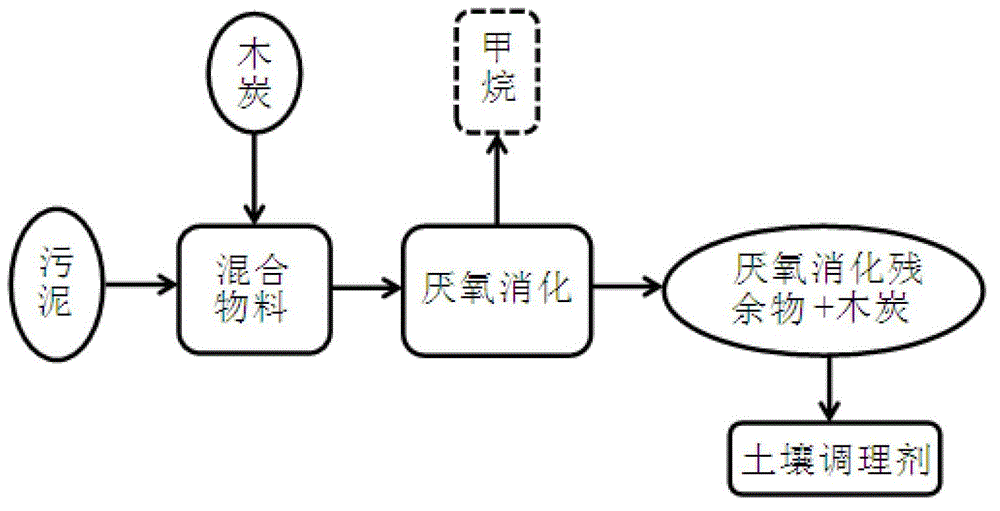

Image

Examples

Embodiment 1

[0022] (1) Take the primary sludge from the urban sewage plant. The TSS (referring to the concentration of suspended matter in the sludge) of the sludge is 10g / L, and the VSS (referring to the organic matter volatilized after the suspended matter in the sludge is calcined at a high temperature of 575°C) Concentration) is 5.9g / L, add charcoal powder 0.1g;

[0023] (2) Put it into a sealed anaerobic digestion equipment, control the culture temperature at 35°C, and control the pH at 7.8; perform anaerobic digestion treatment on the sludge by stirring, and repeat the culture 3 times.

[0024] Using the above-mentioned treatment method, the methane yield of the sludge is increased by 40% compared with the working condition without adding charcoal powder, and the start time of sludge anaerobic digestion is 20% earlier.

Embodiment 2

[0026] (1) Take the secondary sedimentation sludge from the urban sewage plant, the TSS of the sludge is 10g / L, the VSS is 5.9g / L, and add 0.1g of charcoal powder;

[0027] (2) Put it into a sealed anaerobic digestion equipment, control the culture temperature at 35°C, and control the pH at 7.8; perform anaerobic digestion treatment on the sludge by stirring, and repeat the culture 3 times.

[0028] Using the above-mentioned treatment method, the methane yield of the sludge is increased by 40% compared with the working condition without adding charcoal powder, and the start time of sludge anaerobic digestion is 20% earlier.

Embodiment 3

[0030] (1) Take the dewatered sludge from the urban sewage plant, the TSS of the sludge is 8g / L, the VSS is 7.5g / L, and add 0.1g of charcoal powder;

[0031] (2) Put it into a sealed anaerobic digestion equipment, control the culture temperature at 35°C, and control the pH at 7.8; perform anaerobic digestion treatment on the sludge by stirring, and repeat the culture 3 times.

[0032] Using the above-mentioned treatment method, the methane yield of the sludge is increased by 40% compared with the working condition without adding charcoal powder, and the start time of sludge anaerobic digestion is 20% earlier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com