Aerated concrete block and preparation method thereof

A technology of aerated concrete and blocks, which is applied in the field of building materials, can solve the problems of complex preparation process, poor product pore structure, and difficult quantitative production, and achieve low thermal conductivity, uniform and dense pores, and reduce self-weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

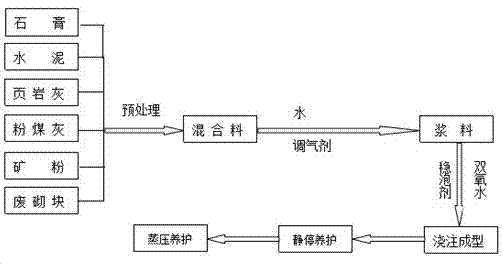

Method used

Image

Examples

Embodiment 1

[0033] An air-entrained concrete block, comprising the following components by weight: 24.7% shale ash, 29.7% mineral powder, 44.6% cement, 0.99% gypsum, 0.11% foam stabilizer, 0.3% air-conditioning agent, 5.0% hydrogen peroxide, and 0.62% water to material ratio;

[0034] 1. the preparation method of foam stabilizer, comprises the following steps:

[0035] Mix 1 part by weight of oleic acid with 2-4 parts by weight of triethanolamine, then dilute with water to a solution with a mass concentration of 30-50%, and add 3-5% cellulose in the diluted solution to the diluted solution by mass percentage ether and mix well.

[0036] 2. The preparation method of air-entrained concrete block, comprises the following steps:

[0037] 1) Pretreatment of raw materials: the above raw materials are mixed and stirred evenly according to the proportion, the fineness of shale ash is 6-30%, and the sieve is 45um, the mineral powder is dried, and the cement is 45.2R composite Portland cement;

...

Embodiment 2

[0044] An aerated concrete block, comprising the following components in parts by weight: shale ash 49.5, mineral powder 14.9, cement 34.7, gypsum 0.99, foam stabilizer 0.11, air-conditioning agent 0.3, hydrogen peroxide 4.0, water-material ratio 0.60; preparation method With embodiment 1.

[0045] Product performance: absolute dry density 286 / kg / m 3 , compressive strength 1.01 / MPa, specific strength 3.46×10 -3 ·N·M / Kg, thermal conductivity 0.0853 / W / (m·k).

Embodiment 3

[0047] An air-entrained concrete block, comprising the following components in parts by weight: 39.5% shale ash, 26.3% mineral powder, 21.9% cement, 10.5% waste block, 1.8% gypsum, 0.11% foam stabilizer, 0.3% air-regulating agent, 3.5% hydrogen peroxide, water material Ratio 0.61; The preparation method is the same as in Example 1, wherein the waste block fineness is 5-20%, and the 45um sieve remains.

[0048] Product performance: absolute dry density 329kg / m 3 , compressive strength 1.33 / MPa, specific strength 4.04×10 -3 ·N·M / Kg, thermal conductivity 0.1013 / W / (m·k).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com