Antioxidant cross-linked polymer and preparation method thereof

A cross-linked polymer and anti-oxidation technology, which is applied in the field of materials science, can solve the problems of inhibiting the cross-linking degree of polyethylene, and achieve the effects of strong anti-oxidation ability, excellent wear resistance and long expected service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

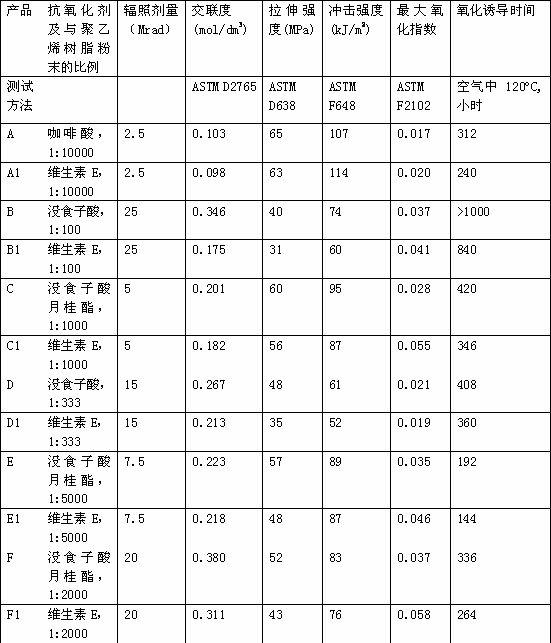

Examples

Embodiment 1

[0030] Step (1). Add 50 grams of caffeic acid into 1 liter of ethanol solvent and mix evenly, then add 500 kilograms of polyethylene resin powder, mix thoroughly, and dry at 80° C. for 5 days to obtain the mixture powder;

[0031]Step (2). Put the mixture powder in the mold and place it on the hot plate of the flat vulcanizer, heat it to 180°C, pressurize it to 50 MPa, and make the mixture powder sinter into a block; then cool down to 110°C and keep The pressure remains unchanged for 72 hours, and then lowered to normal temperature, and a block blank is obtained after demoulding;

[0032] Step (3). At room temperature, irradiate the block blank under a 3MeV high-energy electron beam, each time obtaining an irradiation dose of 0.1 Mrad, and the total irradiation dose is 2.5 Mrad, and the irradiation dose is measured by a standard irradiated chromogenic film ; Obtain the anti-oxidation cross-linked polymer after irradiation, denoted as sample A.

[0033] Sample A is a mixture o...

Embodiment 2

[0040] Step (1). Add 200 grams of gallic acid to 1 liter of acetone solvent and mix evenly, then add 20 kilograms of polyethylene resin powder, mix thoroughly, and dry at 40° C. for 14 days to obtain the mixture powder;

[0041] Step (2). Put the mixture powder in the mold and place it on the hot plate of the flat vulcanizer, heat it to 240°C, pressurize it to 1MPa, and make the mixture powder sinter into a block; then cool down to 130°C and keep the pressure Unchanged for 0.5 hours, then lowered to normal temperature, and a block blank was obtained after demoulding;

[0042] Step (3). At normal temperature, irradiate the block blank under a 10MeV high-energy electron beam, and obtain an irradiation dose of 5Mrad each time, the total irradiation dose is 25Mrad, and the irradiation dose is measured by a standard irradiated chromogenic film; Obtained anti-oxidation highly cross-linked polymer after irradiation, denoted as sample B.

[0043] Sample B is a mixture of cross-linked...

Embodiment 3

[0050] Step (1). Add 100 grams of lauryl gallate to 1 liter of petroleum ether solvent and mix evenly, then add 100 kilograms of polyethylene resin powder, mix thoroughly, and dry at 60° C. for 10 days to obtain the mixture powder;

[0051] Step (2). Put the mixture powder in the mold and place it on the hot plate of the flat vulcanizer, heat it to 200°C, pressurize it to 10MPa, and make the mixture powder sinter into a block; then cool down to 120°C and keep the pressure Keep it unchanged for 24 hours, then drop to normal temperature, and get a block blank after demoulding;

[0052] Step (3). Under normal temperature, irradiate the block blank under a 5MeV high-energy electron beam, and obtain an irradiation dose of 1Mrad each time, the total irradiation dose is 5Mrad, and the irradiation dose is measured by a standard irradiated chromogenic film; Obtain anti-oxidation highly cross-linked polymer after irradiation, denoted as sample C.

[0053] Sample C is a mixture of cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crosslink density | aaaaa | aaaaa |

| Crosslink density | aaaaa | aaaaa |

| Crosslink density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com