Plasma processing system and method

A processing system and plasma technology, applied in the field of plasma processing systems and methods, can solve the problems that are difficult to meet, increase the Arial density of record information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention is described below in the context of an application for the symmetrical deposition of a DLC protective coating on opposite sides of a planar substrate. This application has been published in the aforementioned co-pending application. This application is typical of other plasma processes and geometries in which the potential of the workpiece is established according to the invention, for which purpose the workpiece is not in physical contact with the power source.

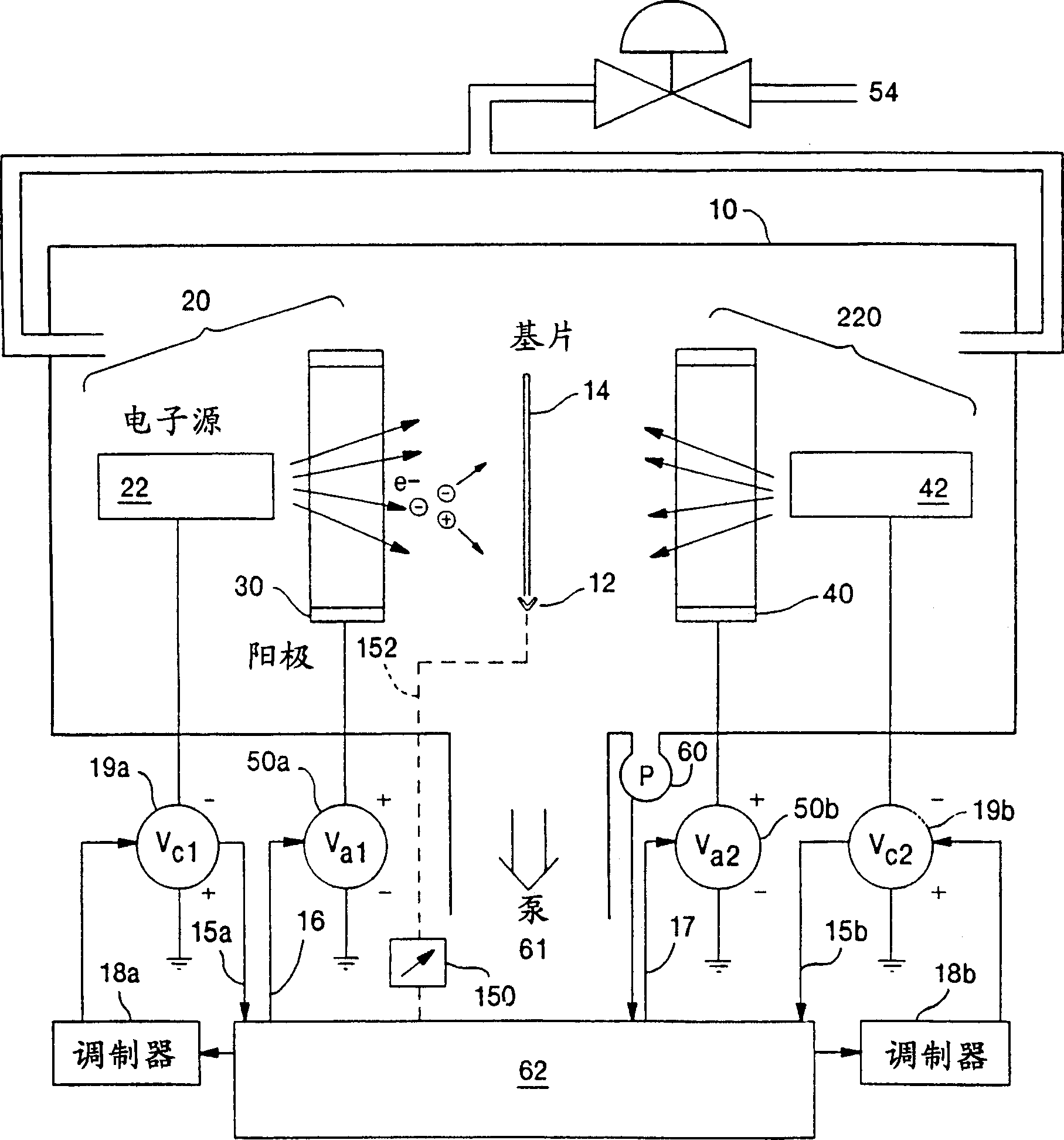

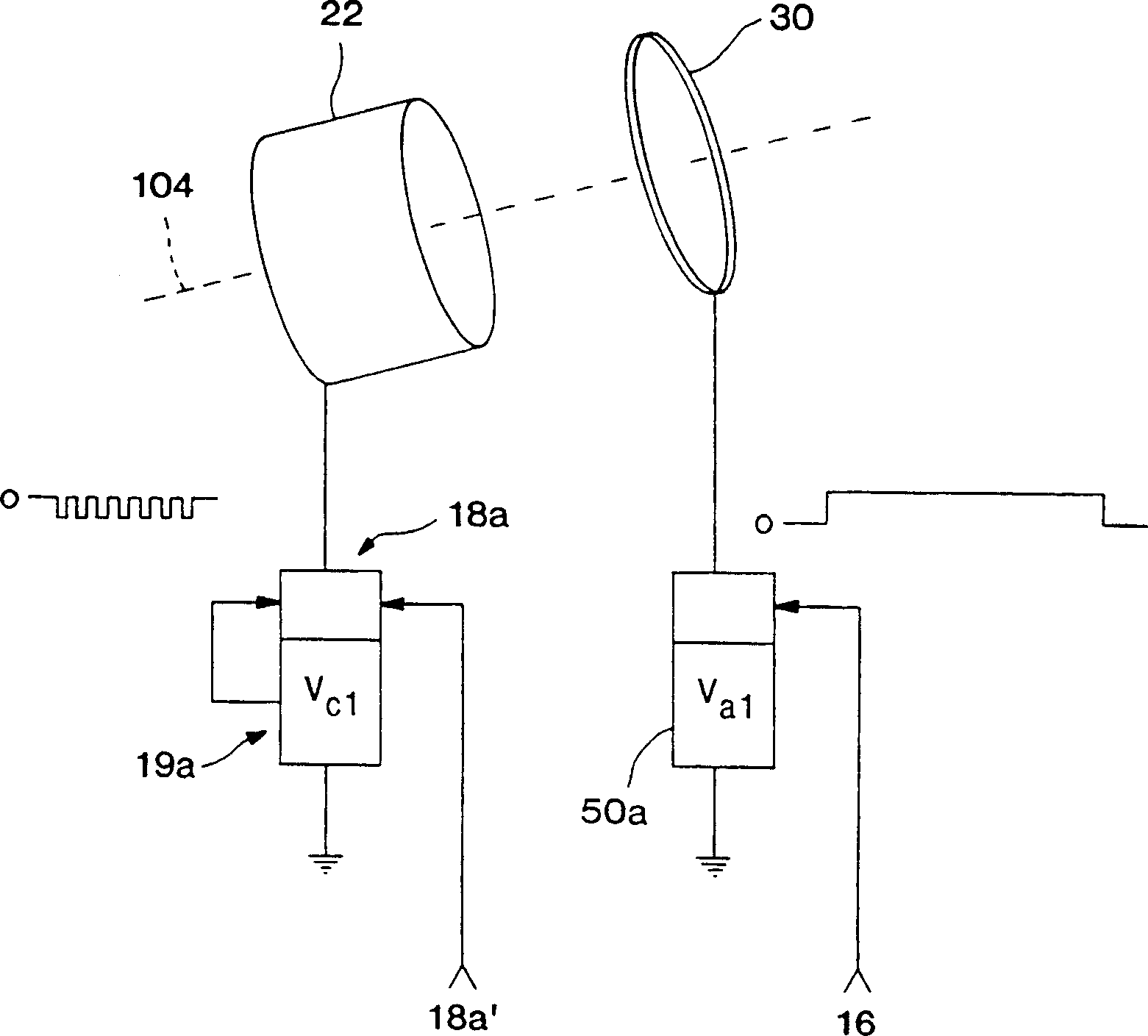

[0030] see now figure 1 , the ion source 20 includes an anode 30 and an electron source 22 . The electron source 22 is connected to the electron source bias power supply 19a. The ion source 220 includes an anode 40 and an electron source 42 located close to the anode 40 . The electron source bias power supply 19 b is connected to the electron source 42 . Depending on the choice of electron source, the electron source power supply (not shown) may need to stimulate the generation of electrons ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com