Low-smoke, halogen-free and flame-retardant irradiation crosslinking polyolefin composite material and preparation method thereof

A composite material and polyolefin technology, applied in the field of flame-retardant polyolefin materials, to achieve the effects of improved mechanical properties, good flame-retardant properties, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take by weight 45 parts of ethylene-vinyl acetate copolymers, 5 parts of maleic anhydride grafted ethylene-vinyl acetate copolymers, 0.5 parts of organically modified montmorillonite, and knead for 10 minutes at 140 ° C in an internal mixer, Then add 50 parts of magnesium hydroxystannate microencapsulated aluminum hydroxide, 1.5 parts of triallyl isocyanurate, 0.4 parts of antioxidant 300, and 0.4 parts of antioxidant DLTP, and mix the components of the raw materials evenly Finally, it is extruded and granulated at 140°C to form an electron beam irradiation cross-linked polyolefin cable material, and then the polyolefin cable material is extruded and coated on the conductive core of the wire and cable, and finally the power and energy are respectively 10KW and 10MeV The cross-linking is irradiated under the electron beam, and the irradiation dose is 120KGy.

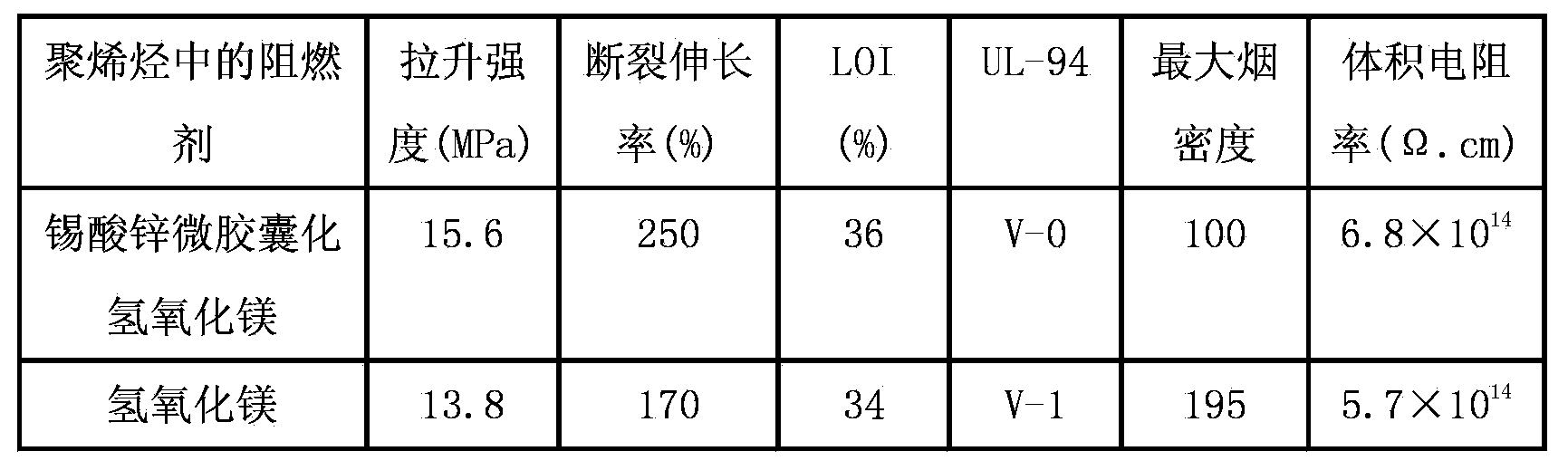

[0022] In order to further verify the performance of the flame retardant synergist microencapsulated metal hydro...

Embodiment 2

[0026] Weigh 50 parts of ethylene-vinyl acetate copolymer, 5 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, and 5 parts of organically modified montmorillonite in parts by weight, and mix in an internal mixer at 140°C for 10 minutes , then add 45 parts of hydrous magnesium aluminate microencapsulated aluminum hydroxide, 0.5 part of triallyl isocyanurate, 0.4 part of antioxidant 300, and 0.4 part of antioxidant DLTP, and mix the components of the raw materials After uniformity, the components of the raw materials are mixed uniformly, extruded and granulated at 160°C to form an electron beam irradiation cross-linked cable material, and then the polyolefin cable material is extruded and coated on the conductive core of the wire and cable, and then in The power and energy are respectively 10KW and 10MeV electron beam irradiation crosslinking, and the irradiation dose is 160KGy.

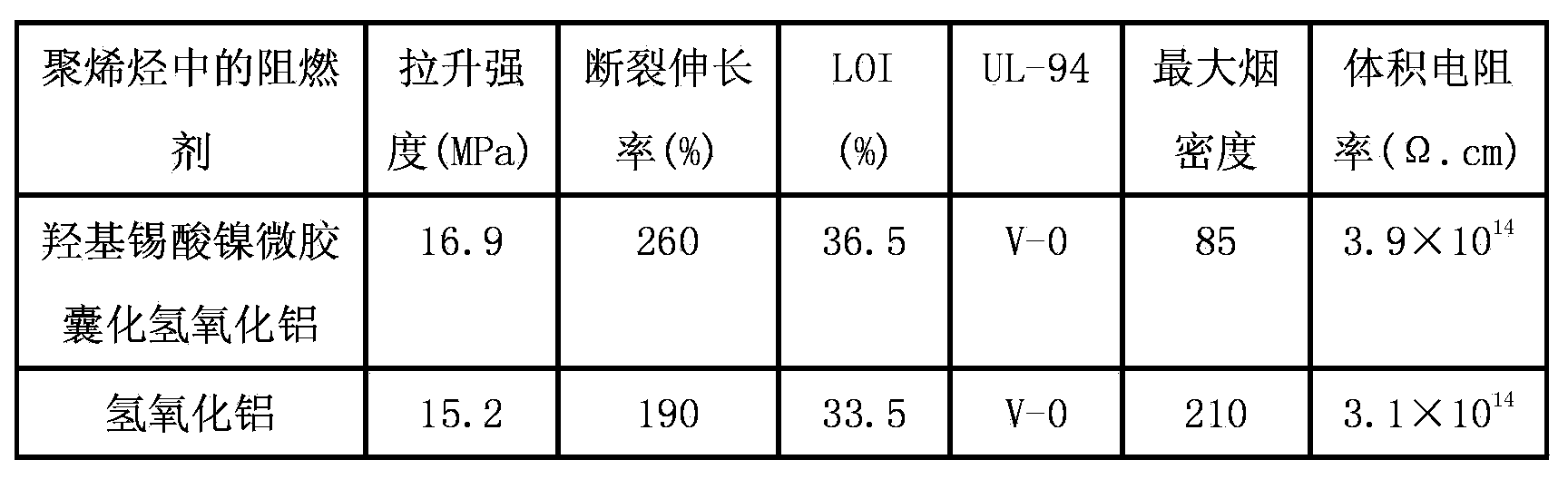

[0027] In order to further verify the performance of the flame retardant synergis...

Embodiment 3

[0031] Weigh 55 parts of ethylene-vinyl acetate copolymer, 5 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, and 5 parts of red phosphorus in parts by weight, mix in an internal mixer at 140°C for 10 minutes, and then add hydroxyl 20 parts of ferric stannate microencapsulated magnesium hydroxide and 20 parts of microencapsulated aluminum hydroxide of ferric stannate, 5 parts of triallyl isocyanurate, 0.05 part of antioxidant 300, and 0.05 part of antioxidant DLTP 0.05 parts, after mixing the components of the raw materials evenly, extruding and granulating at 160°C to form electron beam irradiation cross-linked cable material, and then extruding the polyolefin cable material to coat the conductive core of the wire and cable, and then The power and energy are 10KW and 10MeV electron beam irradiation crosslinking respectively, and the irradiation dose is 80KGy.

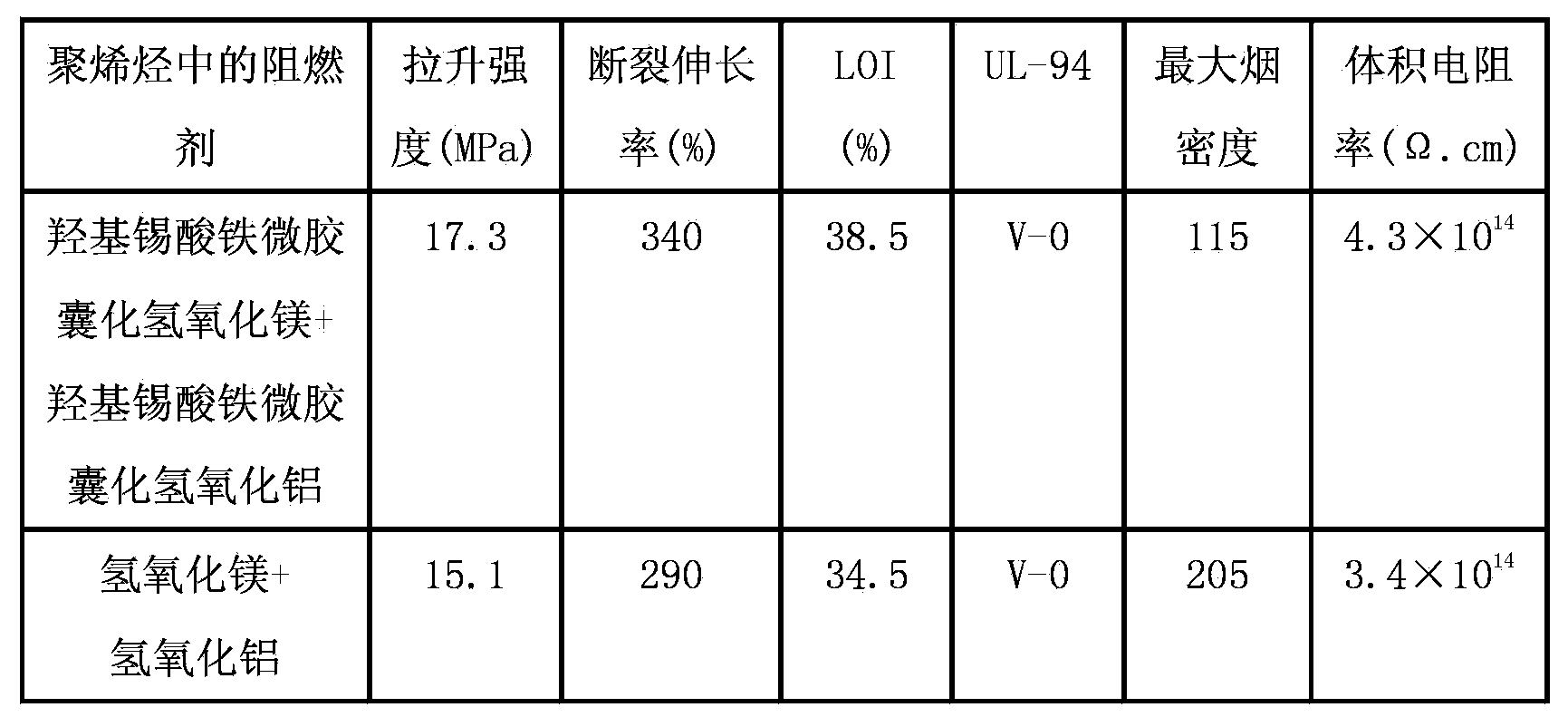

[0032] In order to further verify the performance of the flame retardant synergist microencapsula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com