Method for automatically adjusting the crystal orientation through double-inclination sample stage of transmission electron microscopy

A double-tilt sample stage and electron microscope technology, which is applied in the field of crystal orientation adjustment of transmission electron microscope double-tilt sample stage, can solve the problems of time-consuming, meaningless characterization work, easy amorphization of crystal samples, etc., so as to shorten the operation time. , The effect of sample thickness insensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0029] Now take the sample of face-centered cubic metal aluminum and the unit cell parameter a=0.40488nm as an example to illustrate the specific operation process of the present invention:

[0030] Step 10. Proofread the double-tilt sample stage

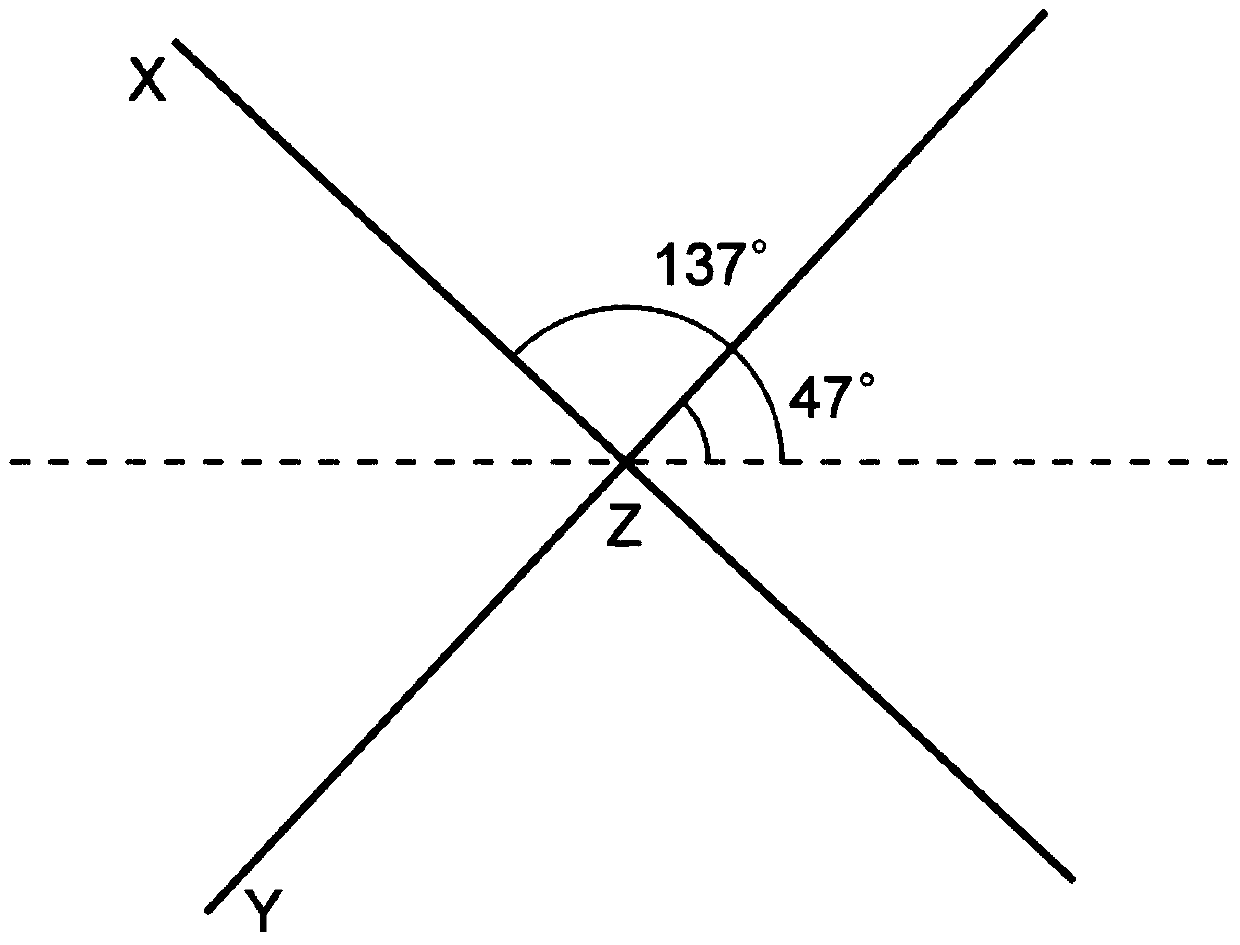

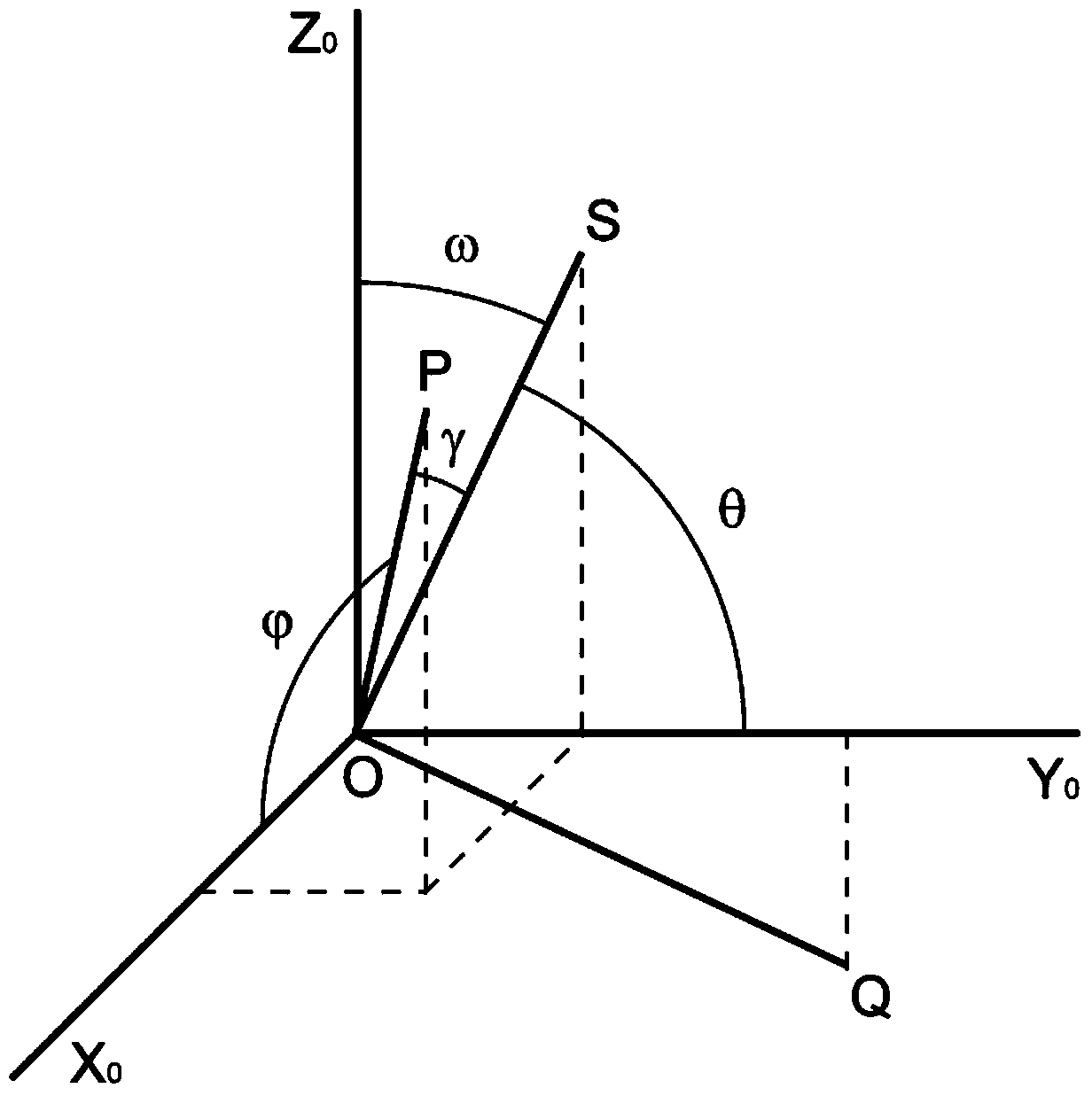

[0031] Make the intersection of the two rotating shafts of the dual-tilt sample stage strictly fall on the axis of the electron beam after the axis is combined; the projection positions of the X-axis and Y-axis of the dual-tilt sample stage are as follows figure 1 As shown, the line at 137° from the horizontal is the projection line of the X axis, and the line at 47° from the horizontal is the projection line of the Y axis.

[0032] Step 20. Record a single crystal electron diffraction pattern with a positive axis

[0033] Fix the objective lens current, select a feature point position in the sample, adjust the tilt angles A and B around the X axis and Y axis, make the single crystal electron diffraction pattern of the feature point in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com