Method for preparing long chain branched polyethylene

A long-chain branched polyethylene technology, applied in the field of long-chain branched polyethylene preparation, can solve problems such as melt collapse, product performance decline, and radiation dose reduction, and achieve easy implementation and shear thinning properties. High, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Get linear low density polyethylene powder (Tianjin Petrochemical, DGH 1875, butene-1 copolymerization, density 0.918g / cm 3 , the melt index is 0.46g / 10min) to obtain pre-irradiated polyethylene after γ-ray irradiation treatment, the irradiation is carried out under air conditions, the absorbed dose is 15kGy, 100g pre-irradiated polyethylene and 900g linear low density polyethylene The powder is mechanically mixed and then melt blended and extruded. The melt blending extrusion is completed in a twin-screw extruder with a screw diameter of 30mm and an aspect ratio of 35.6. The temperature of the extruder from the feeding section to the die is set at 165°C, 180°C, and 190°C in sequence. , 200°C, 200°C, 200°C, 190°C, the rotation speed of the main machine is 300Hz, the feeding rate is 8Hz, and the product is cooled by a circulating water bath and pelletized to complete the preparation process.

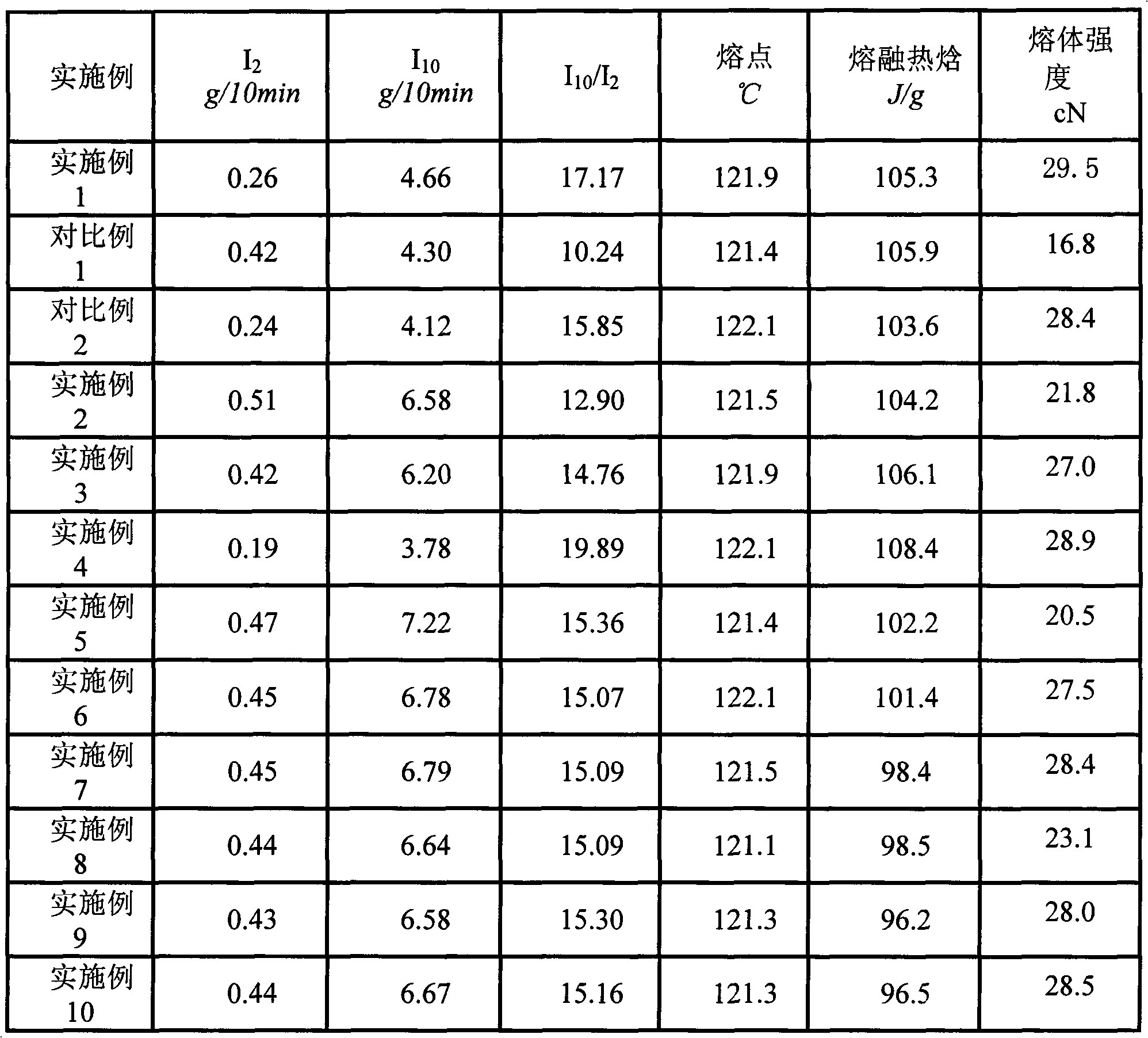

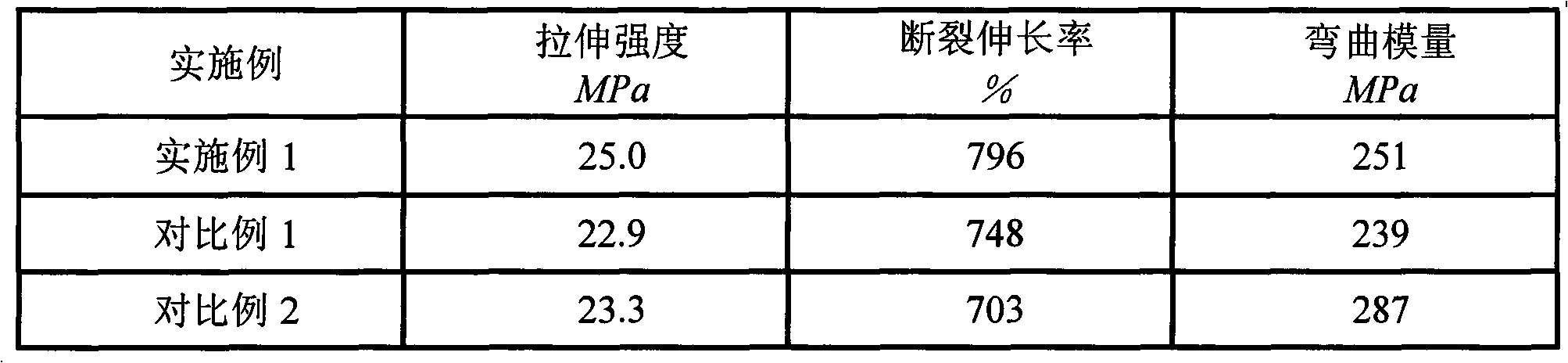

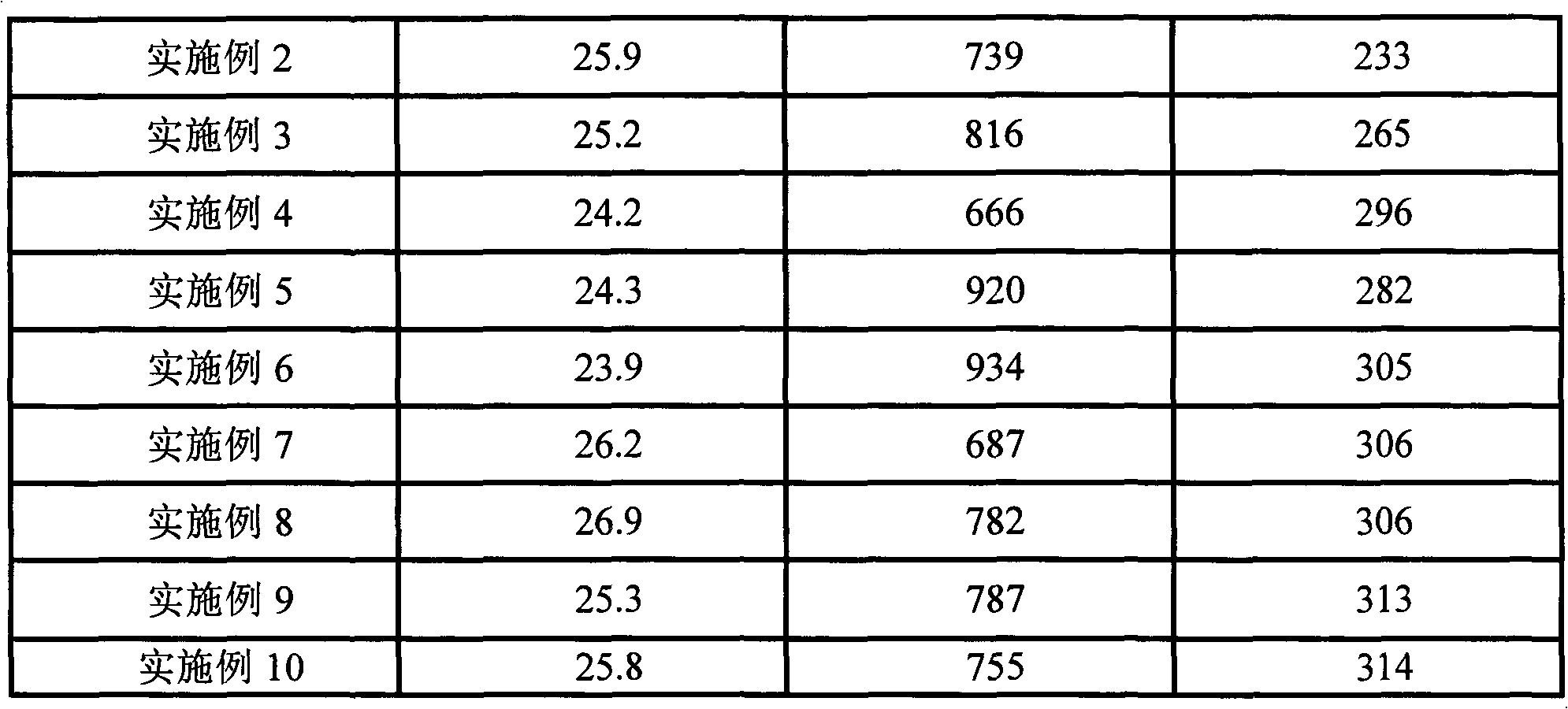

[0030] The properties of the obtained long-chain branched polyethylene are sh...

Embodiment 2

[0037] Get the same linear low-density polyethylene powder 50g of Example 1, obtain pre-irradiated polyethylene after gamma ray irradiation treatment, and the irradiation is carried out under air conditions, and the absorbed dose is 15kGy, and the above-mentioned pre-irradiated polyethylene and 900g of linear low-density polyethylene powder is directly pre-mixed and then subjected to reactive extrusion. The reactive extrusion process is the same as in Example 1, and the product properties are shown in Table 1 and Table 2.

Embodiment 3

[0039] Get the same linear low density polyethylene powder 150g of embodiment 1, obtain pre-irradiated polyethylene after gamma ray irradiation treatment, irradiation is carried out under air condition, and absorbed dose is 15kGy, above-mentioned pre-irradiated polyethylene and 850g of linear low-density polyethylene powder is directly pre-mixed and then subjected to reactive extrusion. The reactive extrusion process is the same as in Example 1, and the product properties are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com