Composite heat insulation tile

A technology of thermal insulation tiles and galvanized steel sheets, applied in the direction of adhesive types, adhesive additives, grafted polymer adhesives, etc. Defects in environmental protection, poor reflection ability of heat insulation tiles, inability to meet customers and other problems, to achieve the effect of good heat insulation effect, weight reduction, and high light reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to the composite heat insulation tile of the specific embodiment of the present invention, the preparation method of the above-mentioned adhesive is provided, comprising the following steps:

[0033] (a) Mix metallocene linear low density polyethylene, polypropylene, styrene isoprene-styrene-block copolymer, initiator, unsaturated carboxylic acid and / or unsaturated anhydride monomer, and extrude Obtain functionalized modified polyethylene masterbatch;

[0034] (b) Mix the functionalized modified polyethylene masterbatch prepared in step (a) with linear low-density polyethylene, ethylene-vinyl acetate copolymer, low-density polyethylene, impact-resistant polystyrene and antioxidant , extruded to obtain the adhesive.

[0035]In step (a), the extruding temperature is 50-230° C., and / or the screw speed is 200-400 rpm, preferably 250-350 rpm. In step (b), the extruding temperature is 50-220° C., and / or the screw speed is 200-400 rpm, preferably 250-320 rpm.

[0...

Embodiment 1-3

[0041] Embodiment 1-3, the preparation of comparative example 1 functionalized modified polyethylene:

[0042] For the functionalized modified polyethylene of Examples 1-3 and Comparative Example 1, after mixing the raw materials uniformly according to the formula ratio (percentage by weight) in Table 1, the plasticized blending process was extruded through a reactive twin-screw extruder. The pellets are prepared, the length-to-diameter ratio of the twin-screw extruder is L:D≥40:1, and the extrusion processing temperature range is 50-230°C.

[0043] Table 1 Example 1-3 and Comparative Example 1 The raw material formula ratio of functionalized modified polyethylene

[0044] Example 1 Example 2 Example 3 Comparative example 1 MLLDPE 95 95 95 95 Homo-PP 3 3 3 3 SIS 2 2 2 POE 2 Bis-2,5-hexane 0.02 0.02 0.02 0.02 Maleic anhydride monomer 1 1 1 1

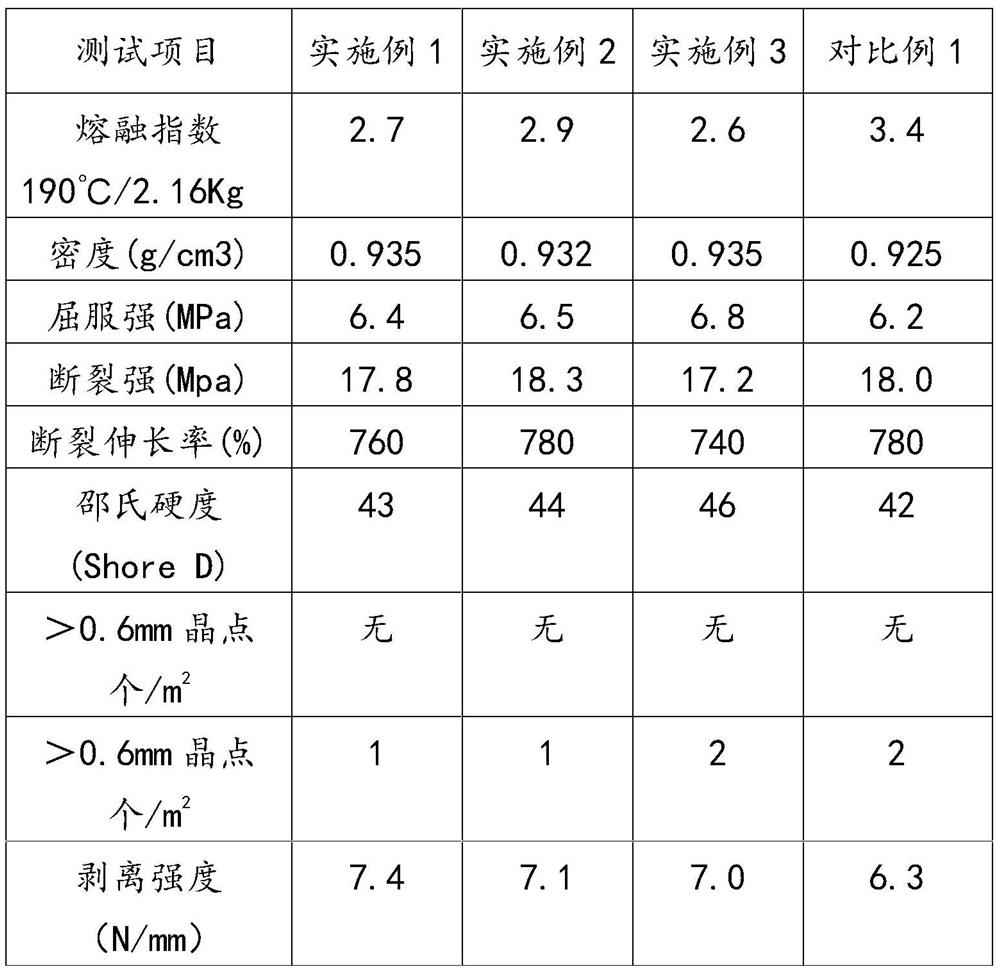

[0045] Preparation of Adhesive Resin for Thermal Insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com