Alkyl silicone continuous production system and production method

A production system, alkyl silicon technology, applied in the direction of coating, etc., can solve the problems of difficulty in meeting high-quality, large-volume hydrocarbon-based silicone resin production requirements, production process termination, high labor intensity, etc., and achieve low labor intensity and fast The effect of fast response and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

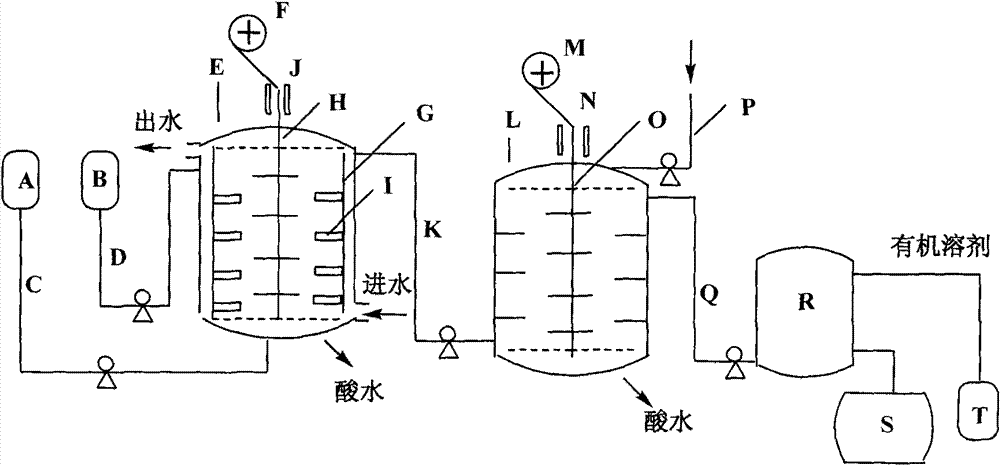

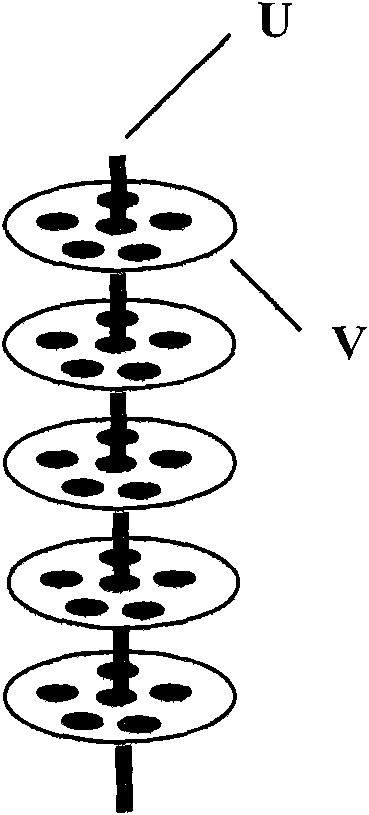

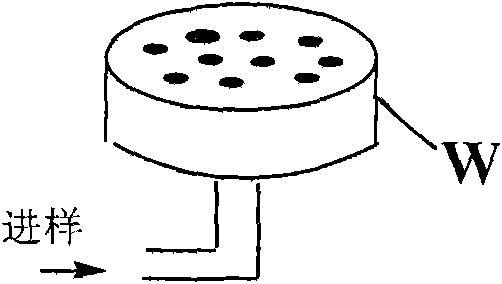

[0033] refer to figure 2, making the reciprocating vibrating sieve plate in the continuous production system of the present invention, the first reciprocating vibrating sieve plate H of the present embodiment and the second reciprocating vibrating sieve plate (O) have the same structure, and can be made of a plurality of sieve plate discs It is fixed on a connecting shaft, and the connecting shaft is connected with a motor and an eccentric wheel. The sieve disc is made of polytetrafluoroethylene, and its diameter is smaller than the inner diameter of the reaction tower E or the washing tower L respectively. The number of multiple sieve discs can be 10, 20, 30, or 50, for example. The sieve discs have circular holes, wherein the opening ratio is not less than 30%, and the diameter of the disc holes is not less than 1 mm. The first reciprocating vibrating sieve plate H is set and fixed on the connecting shaft U by 10 sieve plate discs. The sieve plate discs are installed in pa...

Embodiment 2

[0042] 1) Reactant ratio (weight ratio)

[0043] Monomethyltrichlorosilane 40

[0044] Toluene 60

[0045] 2) Proportion of hydrolyzing agent (weight ratio)

[0046] Ethanol 90

[0047] water 10

[0048] First prepare the reactant solution, according to monomethyltrichlorosilane: Toluene is The weight ratio batching of 40:60 is mixed with the toluene solution of monomethyltrichlorosilane, which will be stored in storage tank A;

[0049] Preparation of hydrolyzing agent: according to the weight ratio of ethanol: water is 90: 10; dissolve ethanol in water, prepare hydrolyzing agent, store in storage tank B;

[0050] According to the reactant solution of monomethyltrichlorosilane: the weight ratio of hydrolyzing agent is 16: 84 to carry out batching;

[0051] From the raw material tank A, the toluene solution prepared in step 1) into monomethyltrichlorosilane is sent from the bottom of the reaction tower E through the pipeline C where the metering pump is installed, and th...

Embodiment 3

[0056] 1) Reactant ratio (weight ratio)

[0057] One methyl trichlorosilane 12~34

[0058] Dimethyldichlorosilane 4~32

[0059] One ethyl trichlorosilane 1~23

[0060] Butyl acetate 55~60

[0061] 2) Proportion of hydrolyzing agent (weight ratio)

[0062] Ethanol 80

[0063] water 20

[0064] refer to figure 2 , the continuous production process for preparing the alkyl silicone resin is the same as in Example 2, the above-mentioned alkyl chlorosilane and toluene are fully mixed and then pressed into the raw material tank A, the ethanol solution is pressed into another raw material tank B, and the ethanol solution passes through the pipeline installed with the metering pump D is added from the top of the reaction tower, and the mixture of the above-mentioned alkylchlorosilane solution is added from the bottom of the reaction tower through the pipeline C installed with a metering pump. The mass ratio of the alkylchlorosilane solution to the ethanol solution is 25:75; star...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com