A kind of linear porous lithium titanate material and its preparation and product

A technology of porous lithium titanate and lithium titanate, applied to the field of linear porous lithium titanate material and its preparation and products, to achieve the effects of low production cost, easy availability of raw materials, and good battery rapid charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

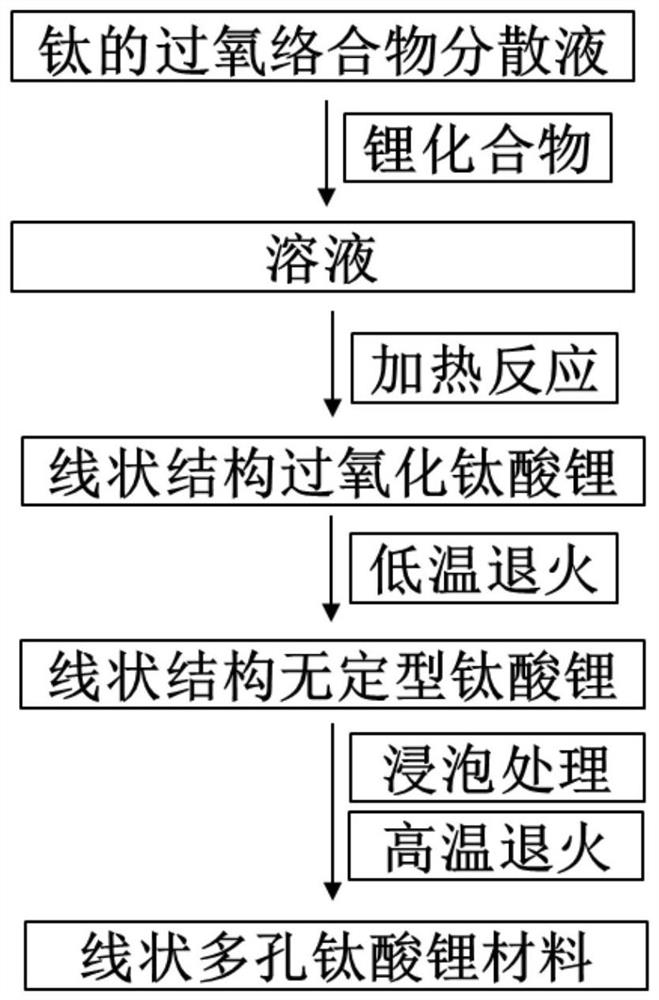

[0071] according to figure 1 Process for preparing linear porous lithium titanate materials. First, 2 g of titanium isopropoxide was dispersed in 100 ml of water, and then 5 ml of hydrogen peroxide with a concentration of 30% was added, and stirred to form a titanium-containing peroxo complex suspension. Next, 3.5 grams of lithium hydroxide was added to the suspension of the above-mentioned peroxo complex, and stirred to form a light yellow transparent solution. Subsequently, the above-mentioned light yellow transparent solution was heated to 80 degrees Celsius and then stirred at constant temperature for 6 hours to obtain a white product of lithium peroxytitanate with a linear structure, which was stopped and separated to obtain a white solid. Subsequently, the above-mentioned white solid was dried and placed in an oven at 200 degrees centigrade for constant temperature annealing treatment for 20 hours to obtain amorphous lithium titanate with a linear structure. Next, soak...

Embodiment 2

[0081] according to figure 1 Process for preparing linear porous lithium titanate materials. Firstly, 0.3 g of titanium sulfate was dispersed in 100 ml of water, then 2 g of urea peroxide was added, and stirred to form a titanium-containing peroxo complex suspension. Next, add 1 gram of lithium peroxide to the suspension of the peroxo complex, and stir to form a light yellow transparent solution. Subsequently, the above light yellow transparent solution was heated to 60 degrees Celsius and then stirred at constant temperature for 24 hours to obtain a white product of lithium peroxotitanate with a linear structure, which was stopped and separated to obtain a white solid. Subsequently, the above white solid was dried and placed in an oven at 150 degrees centigrade for constant temperature annealing treatment for 24 hours to obtain amorphous lithium titanate with a linear structure. Next, soak the amorphous lithium titanate in water at a mass ratio of 1:1000 to water, soak for ...

Embodiment 3

[0083] according to figure 1Process for preparing linear porous lithium titanate materials. First, 8 grams of hydrated titanic acid were dispersed in 80 milliliters of water, and then 25 milliliters of 30% hydrogen peroxide was added, and stirred to form a titanium-containing peroxo complex suspension. Next, add 3 grams of lithium oxide to the above peroxo complex suspension, and stir to form a light yellow transparent solution. Subsequently, the above-mentioned light yellow transparent solution was heated to 100 degrees Celsius and then stirred at constant temperature for 1 hour to obtain a white product of lithium peroxytitanate with a linear structure, which was stopped and separated to obtain a white solid. Subsequently, the above-mentioned white solid was dried and placed in an oven at 250 degrees centigrade for constant temperature annealing treatment for 2 hours to obtain amorphous lithium titanate with a linear structure. Next, the amorphous lithium titanate was soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com