Method for manufacturing precise metal strip resistor

A manufacturing method and technology of metal strips, applied in the direction of non-adjustable metal resistors, resistors, resistance manufacturing, etc., can solve the problems of inability to flexibly change the shape of the lead-out end, difficulty in adapting to installation needs, low production efficiency, etc., and achieve continuous automation Production, increase the high temperature resistance of welds, and reduce the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This embodiment includes the following steps:

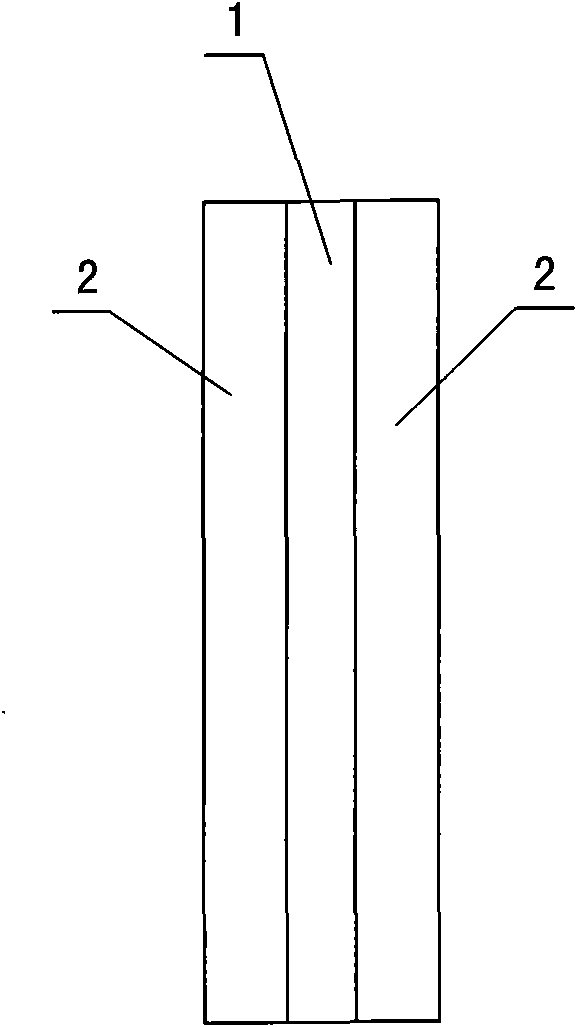

[0019] 1. See figure 1 , take a piece of nickel-chromium alloy strip 1 whose material composition is Cr20%, Cu3%, Al2.8%, Ni balance, thickness is 0.4mm, and width is 5mm. The nickel-chromium alloy strip 1 is a resistor material. Two conductive copper strips 2 with a thickness of 0.4mm and a width of 3.2mm, the conductive copper strips 2 are electrode materials, and the two conductive copper strips 2 are respectively attached to the two sides of the nickel-chromium alloy strip 1, and clamped After clamping and fixing the three parts with the tightening device, clean them;

[0020] 2. Put the three strips fixed together into the welding chamber of the vacuum electron beam welding equipment, and adjust the operating parameters of the electron beam welding equipment to make the vacuum degree 2.2×10 -3 Pa, focus diameter 0.1mm, anode voltage 62KV, welding electron beam power density reaches 10 6 W / cm 2 above, and then weld...

Embodiment 2

[0025] This embodiment includes the following steps:

[0026] see figure 1

[0027] 1. Take a piece of manganese-copper alloy strip 1 whose material composition is Mn20%, Ni3%, and Cu balance, with a thickness of 1mm and a width of 6mm. Take two conductive copper strips 2 with a thickness of 1mm and a width of 20mm. The two conductive copper strips 2 are respectively attached to the two sides of the nickel-chromium alloy strip 1, and the three are clamped and fixed by a clamping device, and then cleaned;

[0028] 2. Put the three strips fixed together into the welding cavity of the vacuum electron beam welding equipment, adjust the operating parameters of the electron beam welding equipment to make the vacuum degree 1.5×10 -3 Pa, focus diameter 0.9mm, anode voltage 70KV, welding electron beam power density reaches 10 6 W / cm 2 above, and then weld the contact parts of the three to form a strip resistor strip;

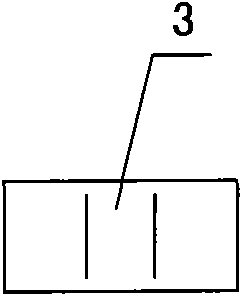

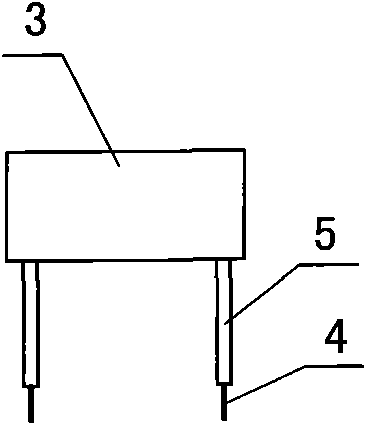

[0029] 3. See Figure 4 , cutting the resistor strip into sev...

Embodiment 3

[0033] This embodiment includes the following steps:

[0034] 1. See Figure 6 , select a manganese-copper alloy sheet 8 with a material composition of Mn13%, Ni3%, and a Cu balance, and a thickness of 0.1mm, and punch out a number of resistors 9 on the alloy sheet 8;

[0035] 2. See Figure 7 , one end of each resistor 9 is disconnected from the alloy sheet 8, and the resistance of each resistor 9 is adjusted. The method adopted is to first use metal cutting means to perform rough adjustment of the resistance value, and then use chemical corrosion to fine-tune the resistance value. tone;

[0036] Then follow the steps below to perform subsequent perfect processing of the resistor body:

[0037] 3. Polish each resistor body 9 and apply a protective agent;

[0038] 4. See Figure 8 , the surface molding plastic layer 10 is carried out on the middle part of the resistor body 9;

[0039] 5. Make a mark on the surface of the plastic layer 10;

[0040] 6. See Figure 9 , ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com