Compound model processing method and device for cutter

A technology of surface compounding and treatment methods, which is applied in the direction of manufacturing tools, measuring/indicating equipment, laser welding equipment, etc., can solve the problems of low processing quality, easy wear, and coolant failure, so as to improve chip quality and wear easily , Reduce the effect of blade wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

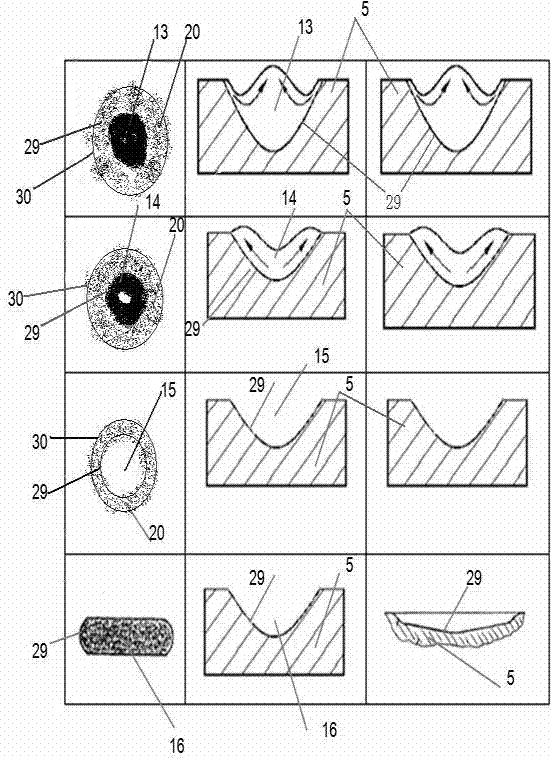

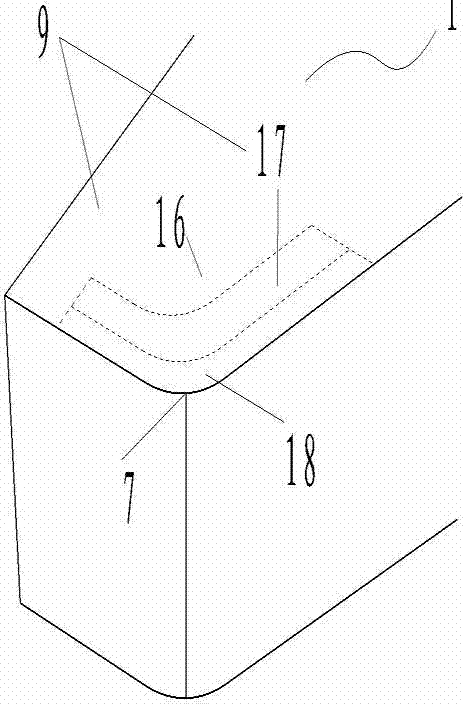

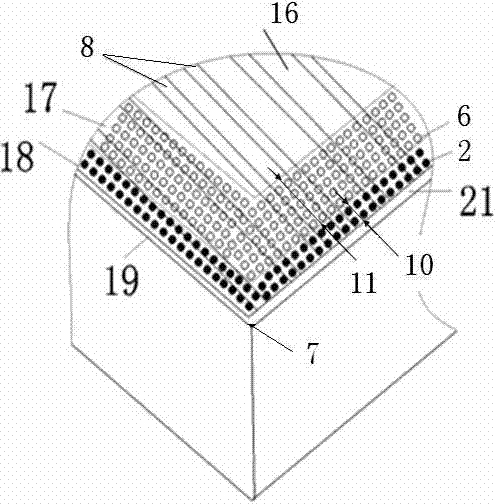

[0036] The specific implementation of the inventive method is as follows:

[0037] (a) Divide the area on the surface of the metal cutting tool 1. The machining-affected area 16 is the area on the surface of the tool that is affected by the cutting operation, including the cutting area 18, the main wear area 17 and the extension to other areas on the surface of the tool 1. The extended area It is the position where the coolant on the surface of the tool 1 is easy to reach, and the cutting zone 18 and the main wear zone 17 are the positions where the coolant is not easy to reach or loses quickly; the cutting zone 18 is the area where the task of removing the material of the workpiece 3 to be cut is completed during the cutting process of the tool 1 ; The main wear zone 17 is the area that supports the chip during the cutting process of the tool 1, and the chip begins to separate from the tool in this area; the boundaries of the cutting zone 18 and the main wear zone 17 are paral...

Embodiment 2

[0053] Example two such as Figure 8 , it differs from Embodiment 1 in that: the scanning system in Embodiment 2 is a manipulator 101; the external optical path of the micro-modeling system is realized by an optical fiber 100 with flexibility, and the optical fiber 100 is connected to the laser 47 and the nozzle 48; the laser 47 produces The laser light is transmitted through the optical fiber 100 and the nozzle 48 is held by the manipulator tip 102 . The manipulator 101 communicates with the upper industrial computer, and is controlled by the latter to implement the same compound modeling processing method for the tool surface as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com