Black silicon solar cell and preparation method therefor

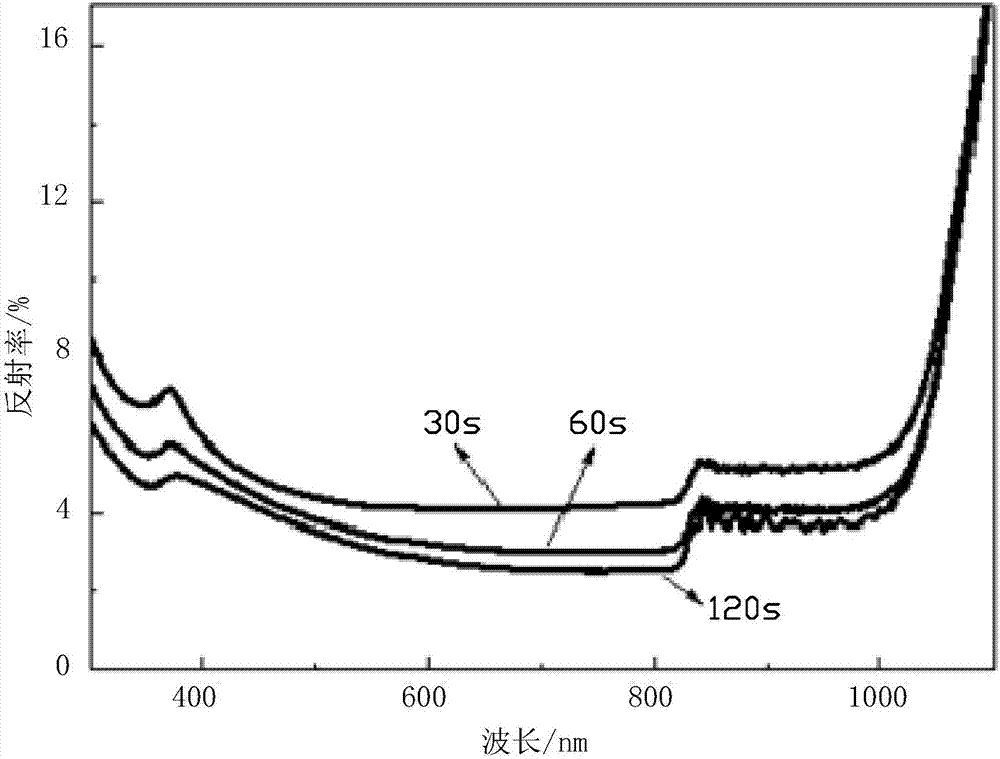

A technology of solar cells and black silicon, applied in the field of solar cells, can solve the problems of narrow solar spectrum absorption range and low photoelectric conversion rate, achieve good surface properties, strong light absorption performance, and improve the effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The invention provides a method for preparing a black silicon solar cell, comprising the steps of:

[0017] Prepare black silicon substrate;

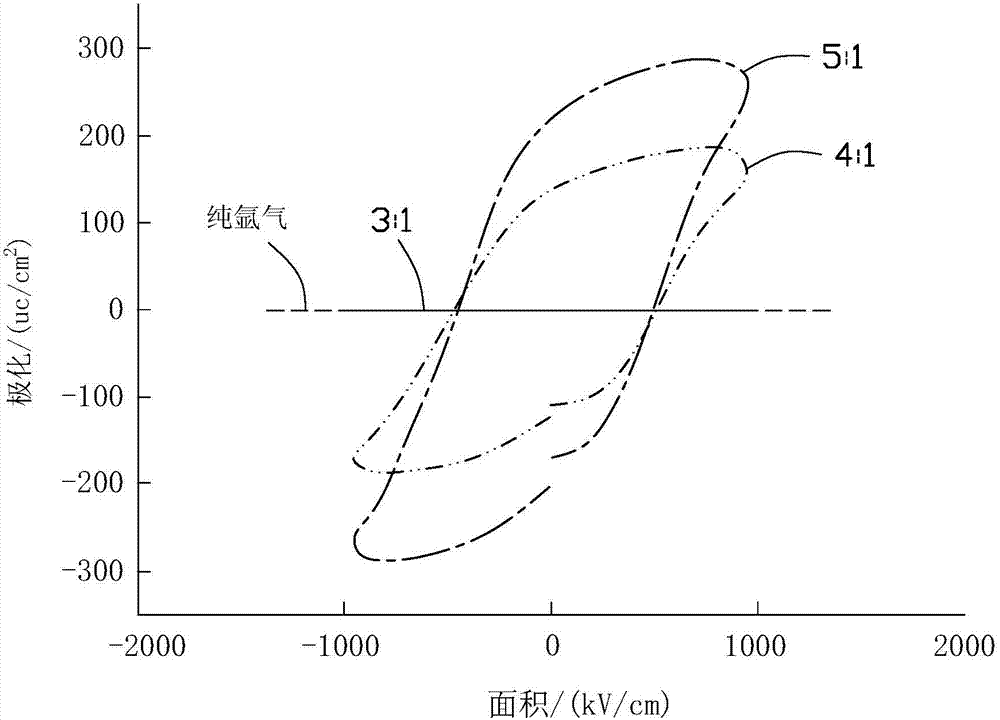

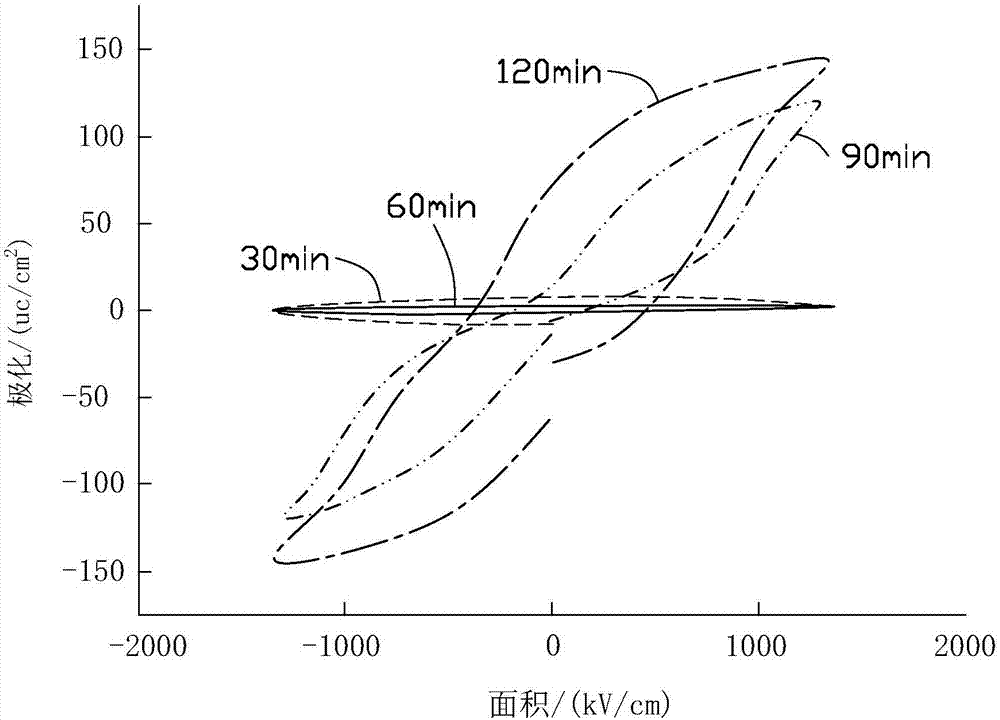

[0018] Sequential deposition of BiFeO on black silicon substrate 3 thin film and ITO thin film.

[0019] According to a specific embodiment of the present invention, the preparation of a black silicon substrate includes the following steps:

[0020] Etching the silicon wafer with a mixed solution of sodium hydroxide and isopropanol to form a silicon wafer with a disordered pyramid structure;

[0021] Depositing silver nanoparticles on the silicon wafer with a disordered pyramid structure, etching the silicon wafer deposited with silver nanoparticles with a mixed solution of hydrogen fluoride and hydrogen peroxide, and then removing the silver nanoparticles with a mixed solution of hydrogen peroxide and ammonia water, A black silicon substrate was obtained.

[0022] According to a specific embodiment of the present invention, ...

Embodiment 1

[0060] Gently rub the surface of the silicon wafer with a commercially available household detergent to roughly remove oil and particles from the surface of the silicon wafer. Put the roughly cleaned silicon wafer into acetone, ethylene glycol, professional cleaning agent, and deionized water for 10 minutes for ultrasonic cleaning, and then dry it with nitrogen gas for later use.

[0061] Put the cleaned and dried silicon wafer into a 20% NaOH solution by mass, corrode it at 85°C for 1 min, remove the surface damage layer, wash it with deionized water and dry it with nitrogen gas for later use.

[0062] The polished silicon wafer was etched with a mixed solution of 1.8% NaOH and 4.8% isopropanol at 83° C. for 35 min to form a silicon wafer with a disordered pyramid structure.

[0063] Deposit silver nanoparticles on a silicon wafer with a disordered pyramid structure, and then use a mixed solution of 10% hydrogen fluoride and 2% hydrogen peroxide to etch the silicon wafer at r...

Embodiment 2

[0071] The preparation method adopted in this embodiment 2 is basically the same as that of embodiment 1, the difference is that the mixed solution of sodium hydroxide and isopropanol used is a mass fraction of 1% sodium hydroxide and 4% isopropanol solution mix. Further, etching is performed by using the mixed solution of 15% hydrogen fluoride and 3% hydrogen peroxide, and the etching time is 1 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com