Perovskite/N-type TOPCon/perovskite laminated solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of high back reflectivity, absorption, and low light utilization rate, and achieve the effects of convenient and simple preparation methods, improved spectral response, and improved light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A kind of preparation method of perovskite / N type TOPCon / perovskite laminated solar cell of the present invention comprises the following steps:

[0050] (1), prepare p+ doped regions on both sides of the silicon substrate after the double-sided texturing treatment;

[0051] (2), any side of the silicon substrate treated in step (1) is put into an acidic solution for etching treatment, to remove the p+ doped region on the back side;

[0052] (3), preparing a tunnel oxide layer and an intrinsic amorphous silicon layer on the back side of the silicon substrate treated in step (2);

[0053] (4) Perform doping treatment on the intrinsic crystalline silicon layer of the silicon substrate treated in step (3), and clean it.

[0054] (5), performing rapid annealing treatment on the silicon substrate after step (4), to form a doped polysilicon film on the tunnel oxide layer; and remove the polysilicon winding on the front side of the silicon substrate;

[0055] (6), composite ...

Embodiment 1

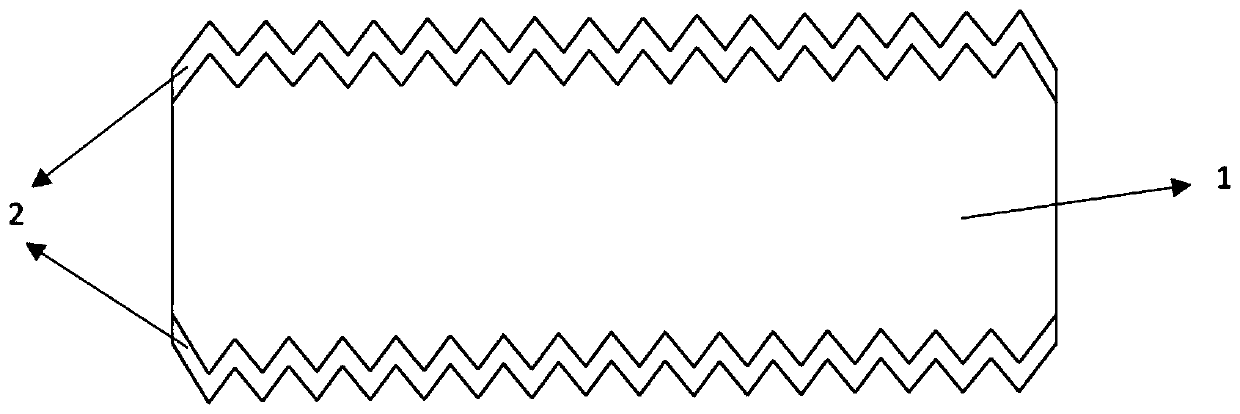

[0079] Step (1), select N-type silicon with a thickness of 150-170 μm, a resistivity of 0.3-2Ω·cm, and a size of 156.75mm×156.75mm as the substrate for double-sided texturing; On the silicon surface, boron tribromide is used as the boron source to prepare the double-sided p+ doped region 2, the diffusion temperature is 850-1000°C, the time is 50-80min, and the square resistance is 80-100Ω / sqr. The battery structure after completing this step is as follows: figure 1 shown.

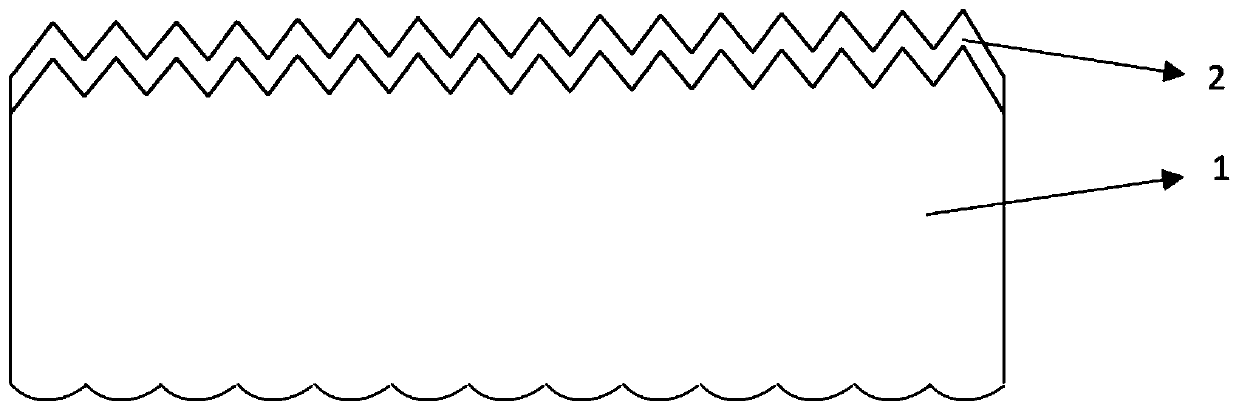

[0080] Step (2), select one side of the N-type silicon after double-sided boron diffusion into HF and HNO 3 , and H 2 SO 4 Etching treatment is carried out in the mixed solution to remove the p+ doped region 2 on the back side to obtain a smooth pyramid surface after etching, wherein, HF:HNO 3 :H 2 SO 4 :H 2 O=1:4:0.6:3, HF mass fraction 20%. The battery structure after completing this step is as follows figure 2 shown.

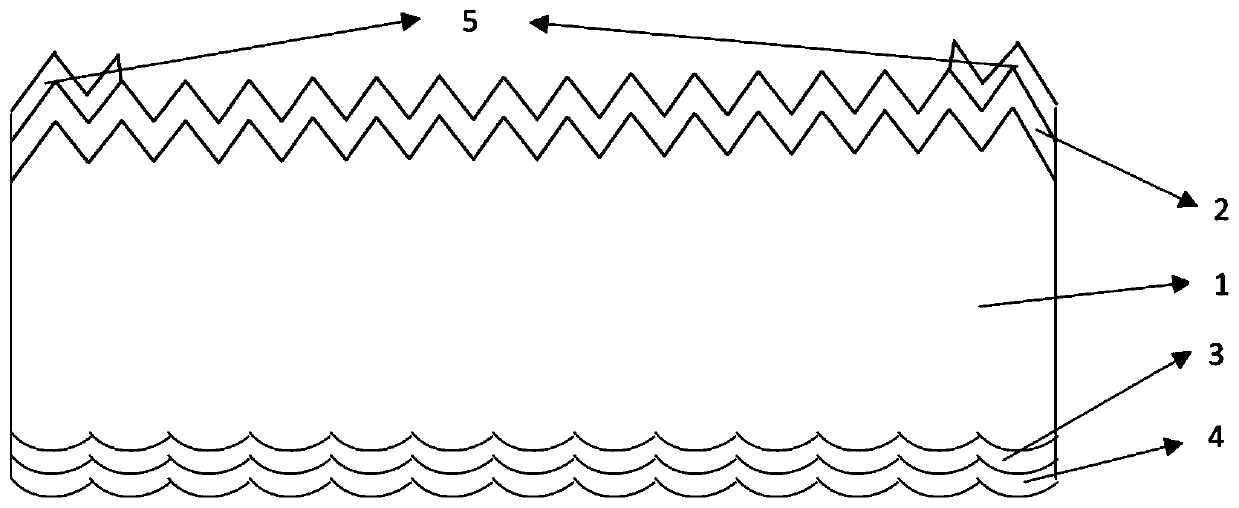

[0081] In step (3), an ultra-thin tunneling oxide layer 3 is prepared on th...

Embodiment 2

[0088] Step (1), select N-type silicon with a thickness of 150-170 μm, a resistivity of 0.3-2Ω·cm, and a size of 156.75mm×156.75mm as the substrate for double-sided texturing; On the silicon surface, boron tribromide is used as the boron source to prepare the double-sided p+ doped region 2, the diffusion temperature is 850-1000°C, the time is 50-80min, and the square resistance is 80-100Ω / sqr. The battery structure after completing this step is as follows: figure 1 shown.

[0089] Step (2), select one side of the N-type silicon after double-sided boron diffusion into HF and HNO 3 , and H 2 SO 4 Etching treatment is carried out in the mixed solution to remove the p+ doped region 2 on the back side to obtain a smooth pyramid surface after etching, wherein, HF:HNO 3 :H 2 SO 4 :H 2 O=1:4:0.6:3, HF mass fraction 20%. The battery structure after completing this step is as follows figure 2 shown.

[0090] In step (3), an ultra-thin tunneling oxide layer 3 is prepared on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com