Front electrode diffraction type local back surface field passivation type crystalline silicon cell preparation method

A technology of crystalline silicon battery and localized back field, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., to achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

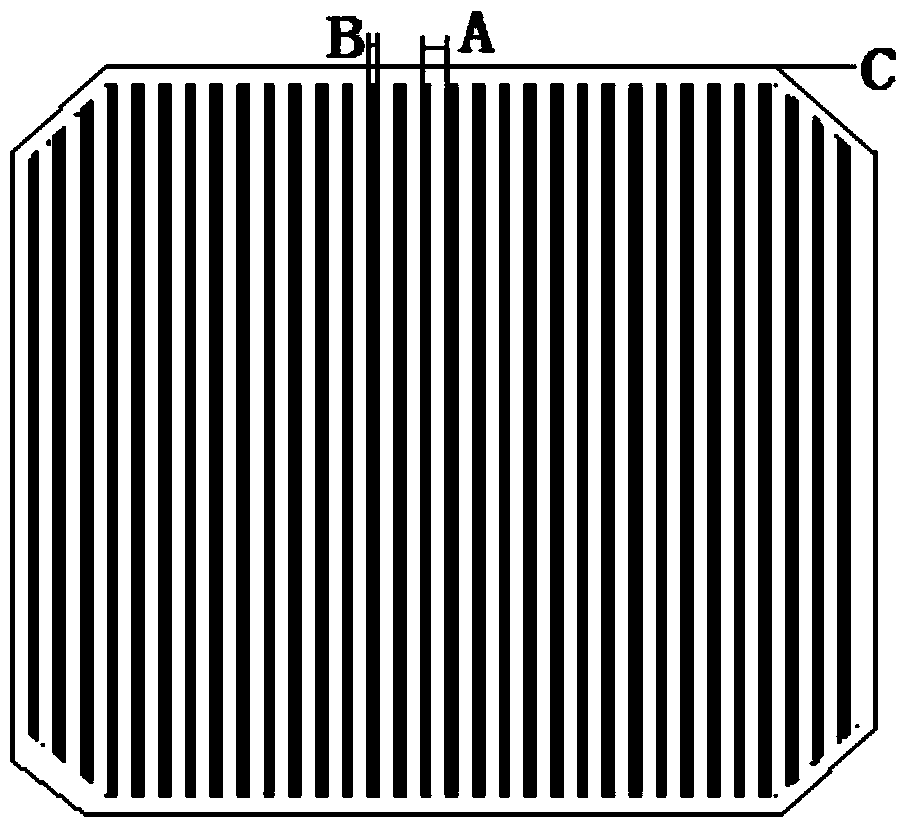

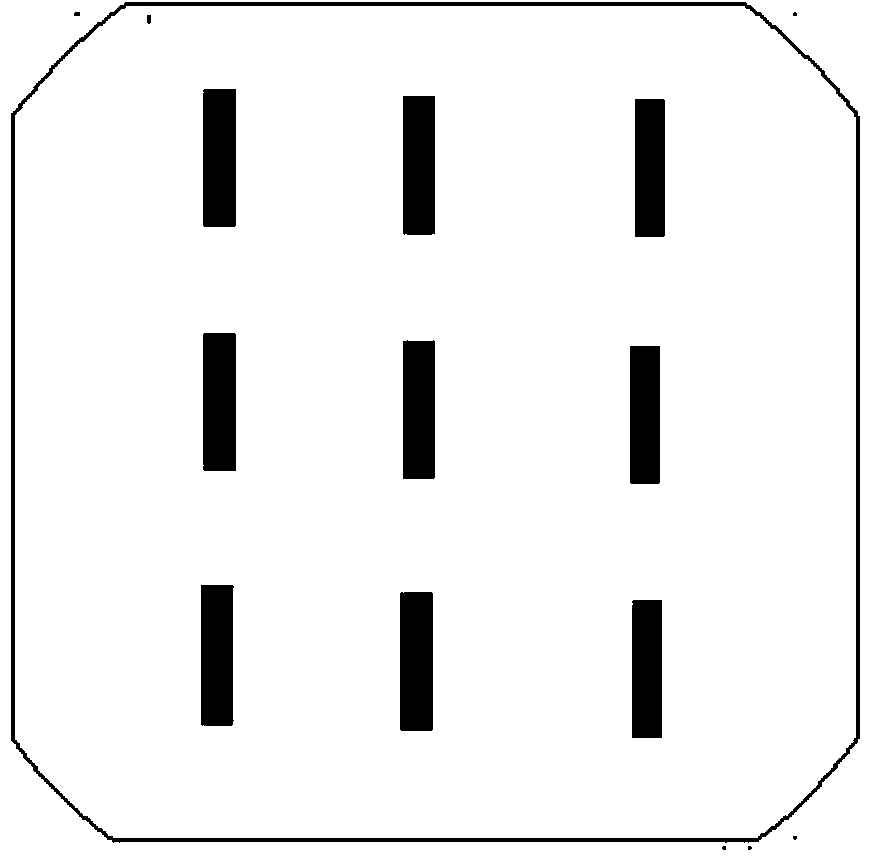

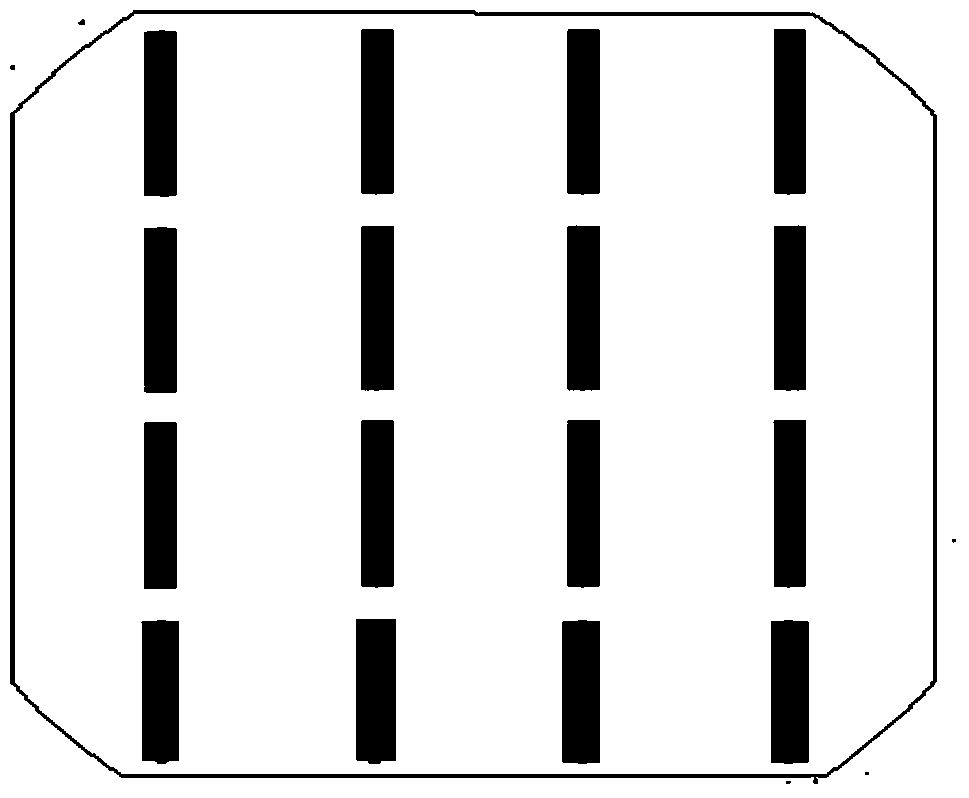

[0036] see Figure 1 to Figure 5 , the preparation method of the front electrode diffraction type localized back field passivation crystalline silicon cell comprises the following steps in turn:

[0037] (1) Choose 156×156mm with a resistivity of 1~3Ω·cm 2 P-type monocrystalline silicon wafer is used as the substrate. To balance the impact of series resistance and shading area on battery performance, a nanosecond green laser with a wavelength of 532nm is used to open 4 rows of holes from the back surface of the silicon wafer. The diameter of the holes is 1.5-2.2mm. The spacing of each row of holes is 12-20mm; the hole array see figure 1 4 rows of small holes in the middle;

[0038] (2) Texture the silicon wafer by single crystal wet method, and prepare a P-N junction with a sheet resistance value of 85-95Ω / □ on the silicon wafer by high-temperature diffusion; the high-temperature diffusion adopts a conventional diffusion furnace, and the parameter settings are shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com