Patents

Literature

50results about How to "Has a passivation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing environment-friendly type anti-corrosive and anti-fingerprint metal surface coating

InactiveCN101392142AImprove anti-corrosion performanceGood fingerprint resistancePretreated surfacesAnti-corrosive paintsEpoxyMicrocrystalline wax

The invention relates to a composition for protecting metal surfaces, in particular to a preparation method of an environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. The composition contains an A component and a B component, the A component takes waterborne epoxy resin as a matrix resin and nano-silica, a silane coupling agent, microcrystalline wax disperse liquid, zirconium complex, deionized water, defoamer and a levelling agent are added, thus obtaining the A component; the B component contains a waterborne epoxy modified amine curing agent and a certain quantity of epoxy curing promoter. The two components are mixed and stirred evenly at a ratio of 4:1 to 3:1 to form the environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. After coating, metal can be heated by going through a baking channel at a certain temperature, the film forming time can be controlled by adjusting the heating period and finally a transparent coating layer which has quite good anticorrosive protection function over metal and fingerprint resistant function is formed.

Owner:TONGJI UNIV

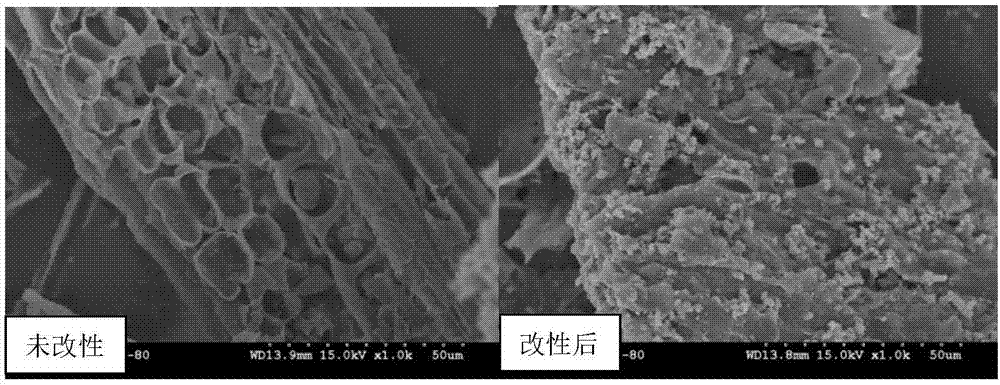

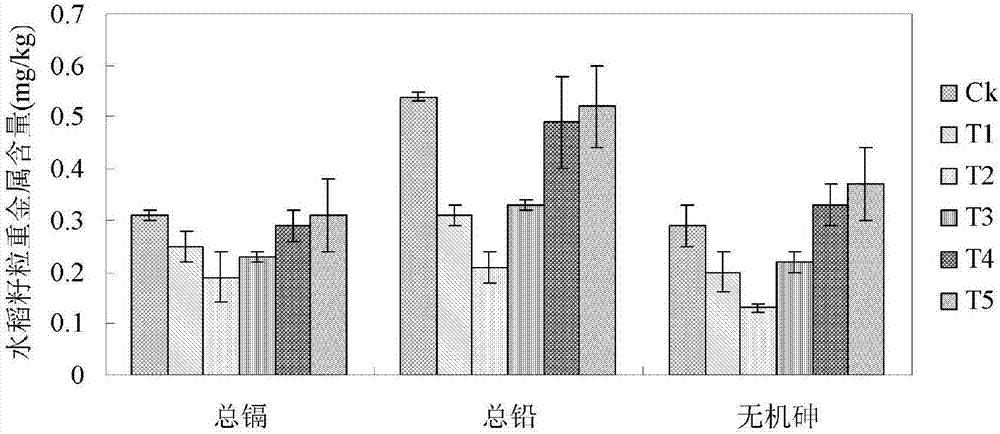

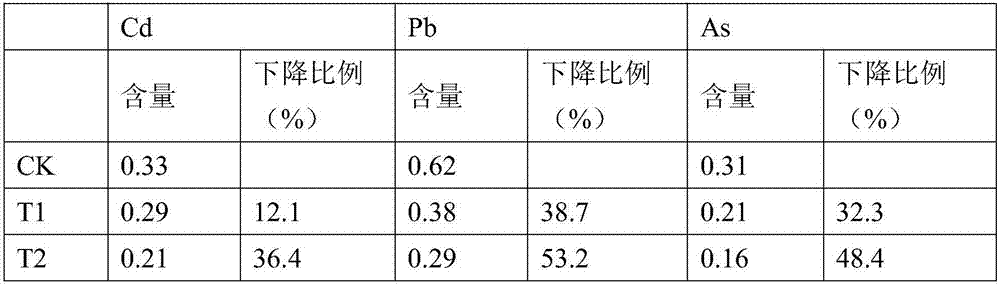

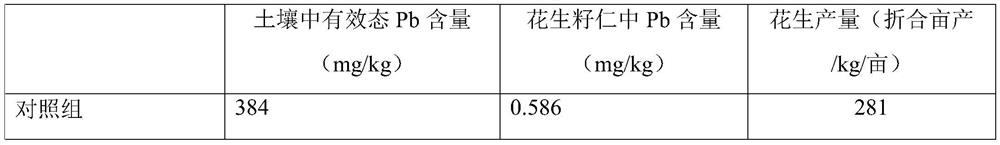

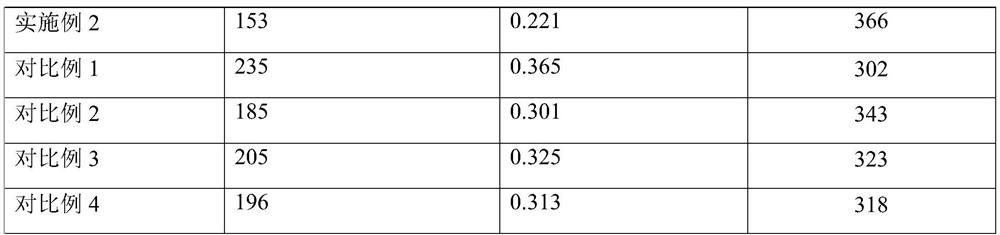

Soil heavy metal restoration agent and preparation method thereof

InactiveCN107502357AHas a passivation effectImprove enrichment capacityAgriculture tools and machinesOther chemical processesSoil heavy metalsManganese oxide

The invention discloses a soil heavy metal restoration agent and a preparation method thereof. Modified biomass charcoal impregnated by calcium-rich element and iron and manganese oxides is adopted as the carrier, and a nanoscale magnetic material is employed to coat the carrier. The product has a particle size of 0.25-5mm, and has a Fe content of 2-5%, a Mn content of 5-10%, and a Ca content of 10-15%. The restoration agent has certain restoration effect on single and compound pollution of cadmium, chromium, arsenic, lead and mercury under different pH backgrounds, thus having certain contribution effect on contaminated soil restoration and food safety. The restoration agent prepared by the method provided by the invention can fully and effectively utilize restoration materials with special passivation effect on heavy metals, and achieves the purpose of spectral restoration of heavy metal contaminated soil.

Owner:NANJING AGRICULTURAL UNIVERSITY

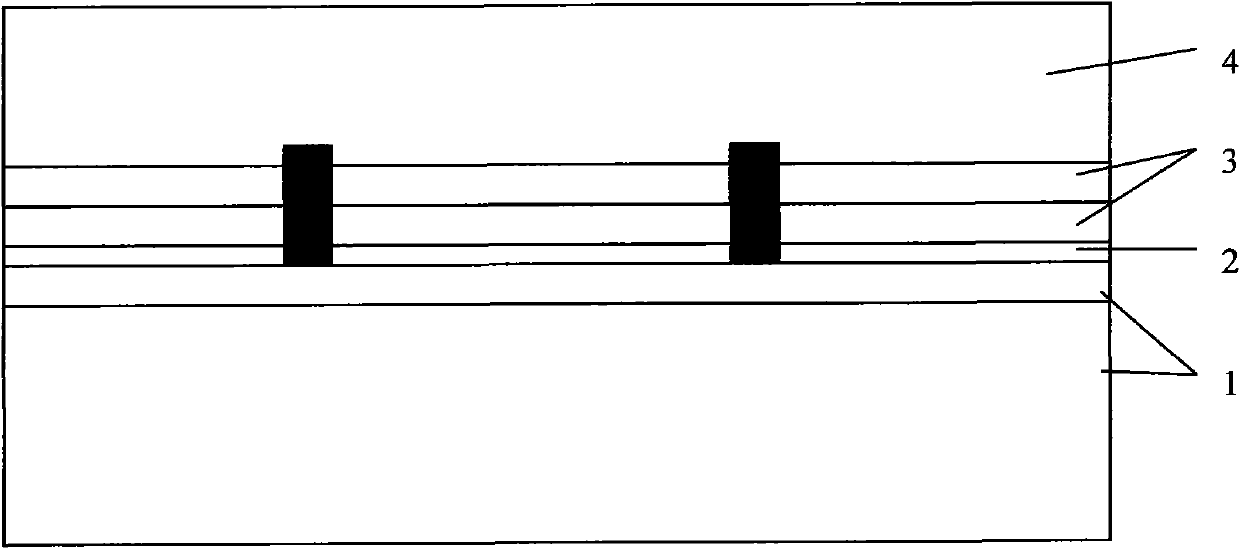

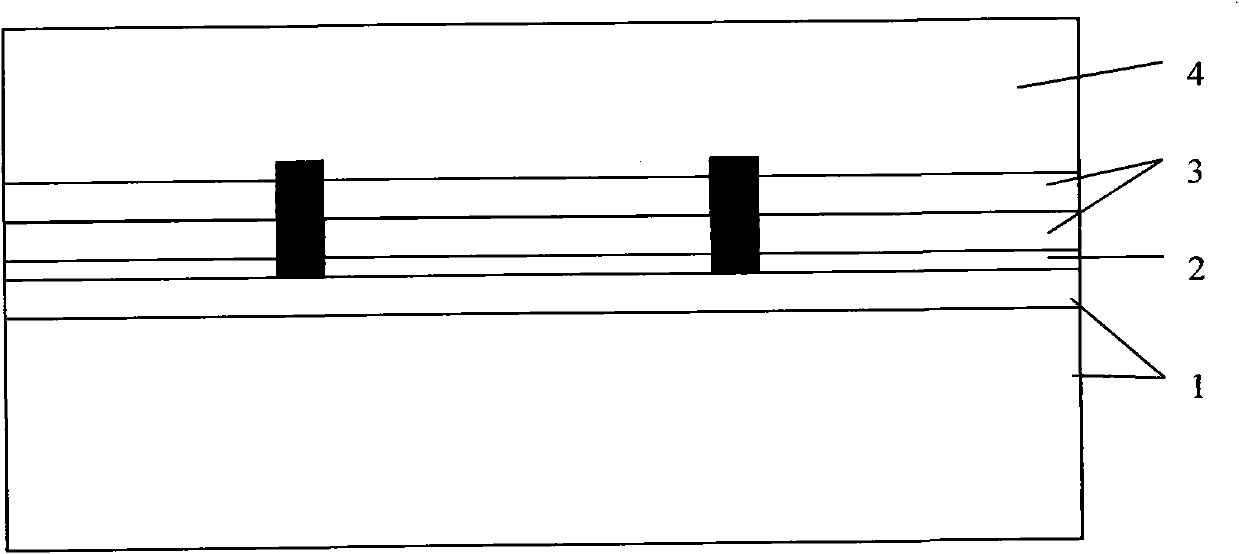

Multilayer anti-reflection film for solar cell and preparation method thereof

InactiveCN102005485AHas a passivation effectSimple preparation processFinal product manufactureSemiconductor devicesRefractive indexEngineering

The invention discloses a multilayer anti-reflection film for a solar cell and a preparation method thereof. The method comprises the following steps of: generating a layer of SiO2 film with the thickness between 5 and 40nm on a window layer of the solar cell; depositing the anti-reflection film with the thickness of between 50 and 100nm on the SiO2 film; and coating ethylene-vinyl acetate (EVA) and a glass envelope on the anti-reflection film. The anti-reflection film is a pervious film of which the refractive index is between 2.3 and 2.4. A TiO2-based anti-reflection film has passivation effect, has anti-reflection effect after packing components and can replace the conventional SiNx single-layer anti-reflection film commonly used in the industry, and the antireflection effect and the passivation effect can be comparable with those of SiNx. A multilayer film structure has a simple preparation process and low cost and is a relatively ideal structure.

Owner:浙江首科科技有限公司

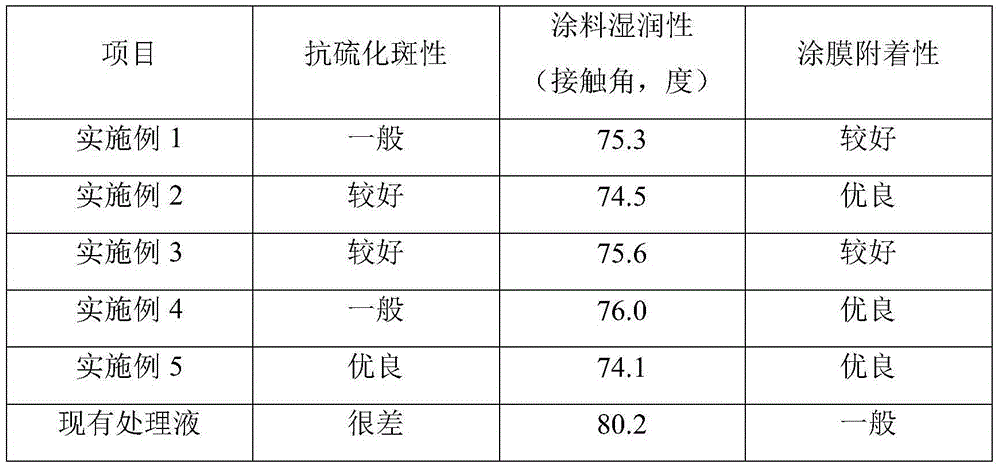

Tinned steel plate surface treatment solution and preparation method thereof

ActiveCN104357825AGuaranteed corrosion resistanceGood adhesionMetallic material coating processesChromium freePhosphate

The invention discloses a tinned steel plate surface treatment solution and a preparation method thereof. The surface treatment solution contains 2-25 g / L disodium hydrogen phosphate, 2-13 g / L sodium pyrophosphate, 1-15 g / L ammonium hydrofluotitanate, 1-10 g / L potassium fluosilicate, 2-14 g / L nickel nitrate, 1-12 g / L zirconium titanate, 1-10 g / L sodium metaaluminate, 5-12 g / L manganese dihydrogen phosphate, 2-5 g / L sodium phytate and 1-7 g / L oxalic acid. The preparation method comprises the following steps: a. adding the disodium hydrogen phosphate and sodium pyrophosphate into deionized water, and stirring; b. adding the ammonium hydrofluotitanate, potassium fluosilicate, nickel nitrate, zirconium titanate, sodium metaaluminate and manganese dihydrogen phosphate; and c. regulating the pH value of the solution to 3-5 with phosphoric acid. On the basis of chromium-free passivation, the surface treatment solution ensures the corrosion resistance of the tinned plate without degrading the sulfur resistance, and also has excellent paint adhesiveness.

Owner:深圳市九久电子科技有限公司

Preparation method for phosphite- chitosan oligosaccharide composite biological medical fertilizer

InactiveCN103819274APromote growthImprove anti-virusFertilizer mixturesCHITOSAN OLIGOSACCHARIDEBiomass

The invention relates to a preparation method for a phosphite-chitosan oligosaccharide composite biological medical fertilizer. The phosphite- chitosan oligosaccharide composite biological medical fertilizer is prepared from phosphite, chitosan oligosaccharide and biomass vinegar in a weight ratio of 40-60 to 5-15 to 200-375; a combination technology is adopted to prepare the compound fertilizer which integrates the effects of pesticide and fertilizer into a whole and the preparation method comprises the following steps: preparing a chitosan oligosaccharide-biomass vinegar compound liquid; preparing a phosphite-biomass vinegar compound liquid; preparing the phosphite-chitosan oligosaccharide composite biological medical fertilizer. The phosphite-chitosan oligosaccharide composite biological medical fertilizer is a bio-fertilizer with double effect of pesticide and fertilizer and ability of both prevention and treatment; the medical fertilizer is free from residue and pollution, and is safe and environment-friendly; the medical fertilizer is not only a bio-fertilizer but also a bio pesticide; meanwhile, the fertilizer the fertilizer is also a situ repair agent for soil polluted by heavy metals.

Owner:FUJIAN YONGCHEN BIOTECH DEV

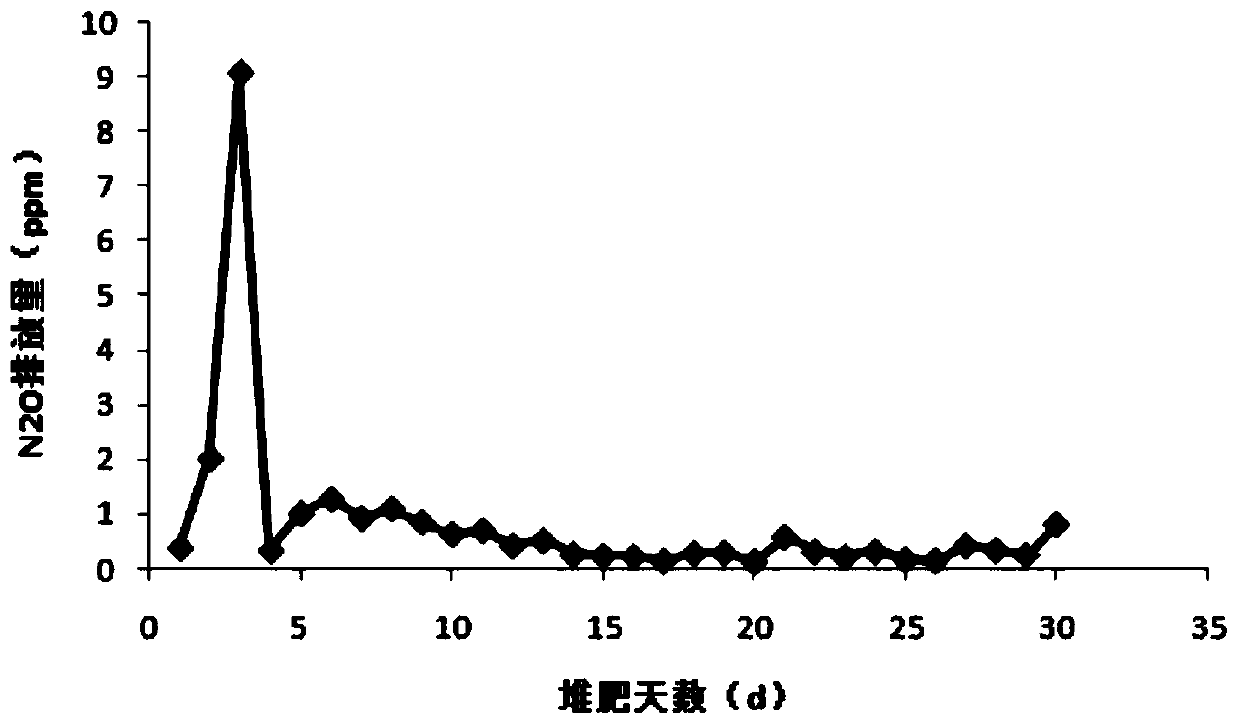

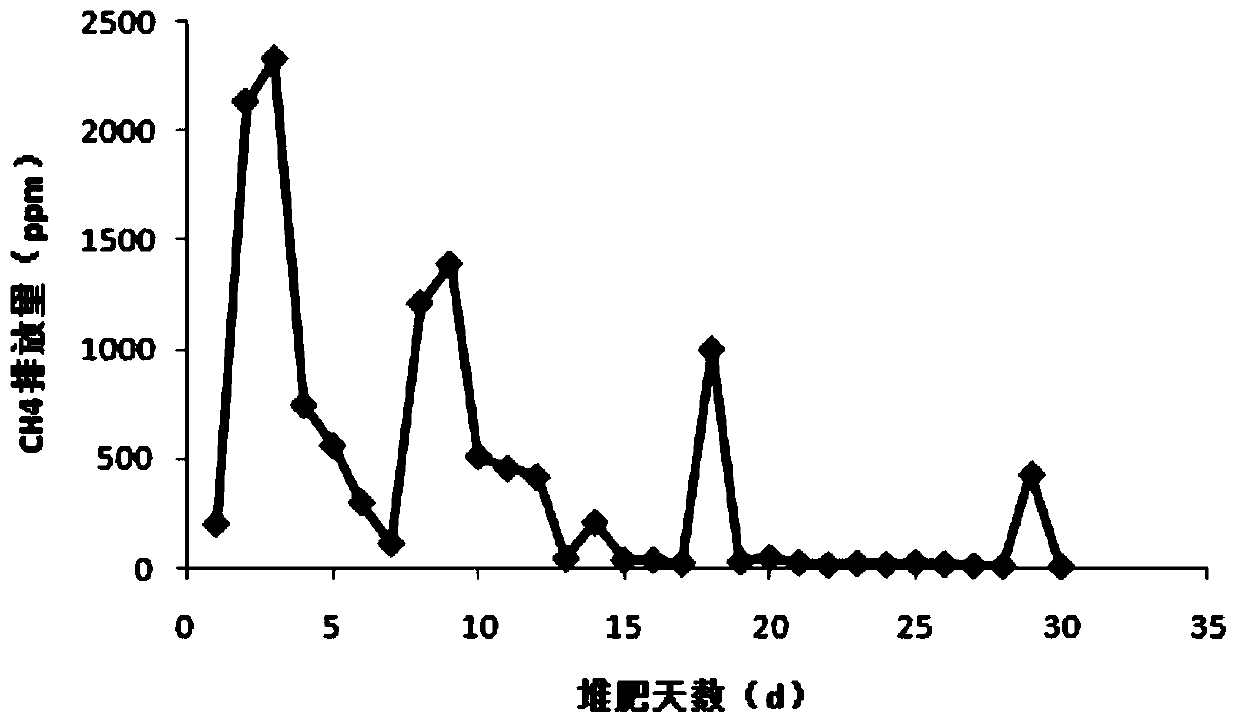

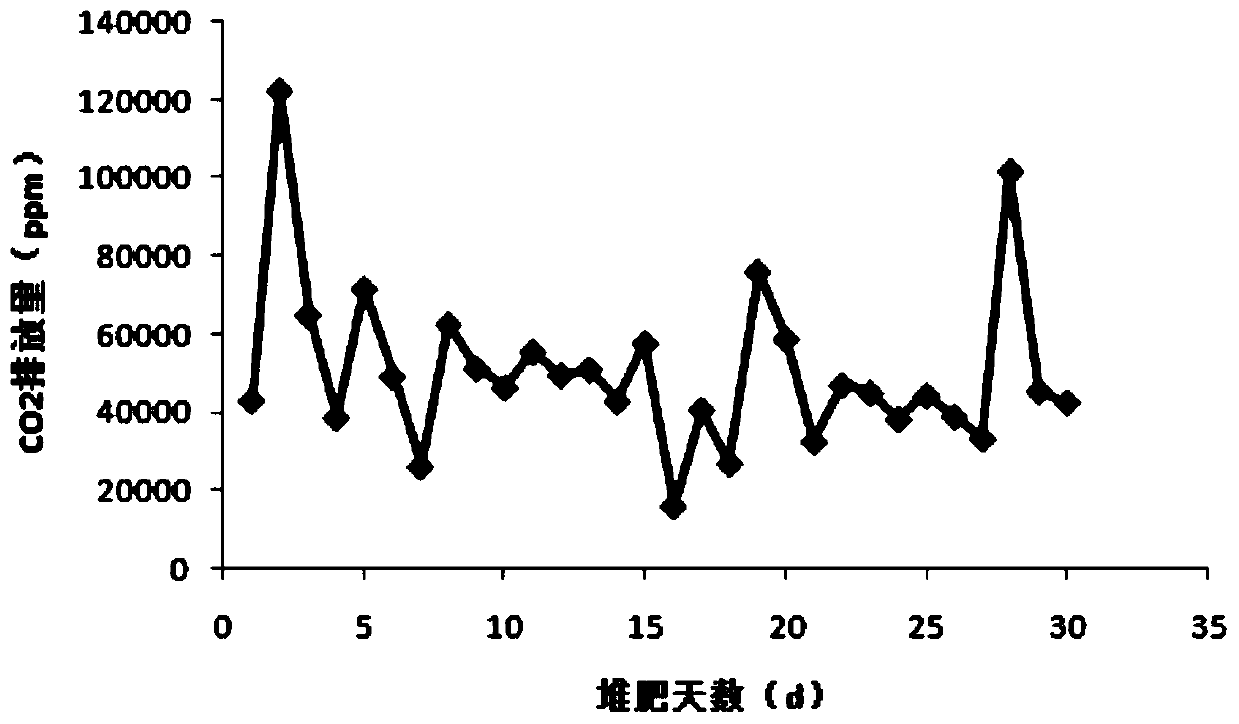

Low-emission static oxygen-control biologically-enhanced humification composting method

InactiveCN111072409AMix evenly and fullyEmission reductionBio-organic fraction processingExcrement fertilisersMicrobial agentCompost

The invention relates to a low-emission static oxygen-control biologically-enhanced humification composting method. The method comprises the following steps: respectively crushing organic wastes intoparticles with the particle size of less than 5 cm; uniformly mixing and stirring according to a weight ratio; adding a biologically-enhanced composite microbial agent accounting for 0.1-0.5% of the total amount of the mixture and allowing the water content of the organic waste stock to be 60-65%, the carbon-nitrogen ratio to be 23-30, and the volume weight to be 700-950 kg / m<3> to obtain a composting raw material. Air with a supply amount of 0.40-0.45 m<3> / h / m<3>, air with a supply amount of 0.28-0.38 m<3> / h / m<3> and air with a supply amount of 0.13-0.26 m<3> / h / m<3> are respectively providedthrough high-pressure aeration pipes in the three stages of compost temperature rise, high temperature and temperature reduction to fully decompose organic matters; and after fermentation is completed, the water content of a finished product fertilizer is 33-42%, the volume weight is reduced to 400-650 kg / m<3>, the volume of a pile body is reduced by 30-50%, and meanwhile, emission of methane, nitrous oxide, ammonia gas and hydrogen sulfide is reduced.

Owner:BEIJING GOLDENWAY BIO TECH

Deodorizing and passivating cleaning agent for oil refining devices

ActiveCN102634423AHas a passivation effectDispersing and compatibilizingNon-surface-active detergent compositionsMetallic material coating processesDiamineSodium silicate

A deodorizing and passivating cleaning agent for oil refining devices belongs to the technical field of device cleaning agents and is characterized by including (in weight): 20 parts of passivator, 10-14 parts of deodorant, 7-9 parts of active components, wherein the deodorant is compounded by low-alkali sodium hypochlorite, ultrafine sodium silicate and glyoxal diamine, the active components aretetrakis hydroxymethyl phosphonium sulfate (THPS) compound, and the passivator is low-alkali sodium hypochlorite and THPS. Compared with the prior art, the deodorizing and passivating double-effect cleaning agent for the oil refining devices has two functions of deodorizing and passivating, and two effects of deodorizing and passivating can be realized by one-step cleaning process during use of the oil refining devices. Equipment can be cleaned at normal temperature and normal pressure during use, heating is omitted and safety and convenience are achieved.

Owner:王春玲 +1

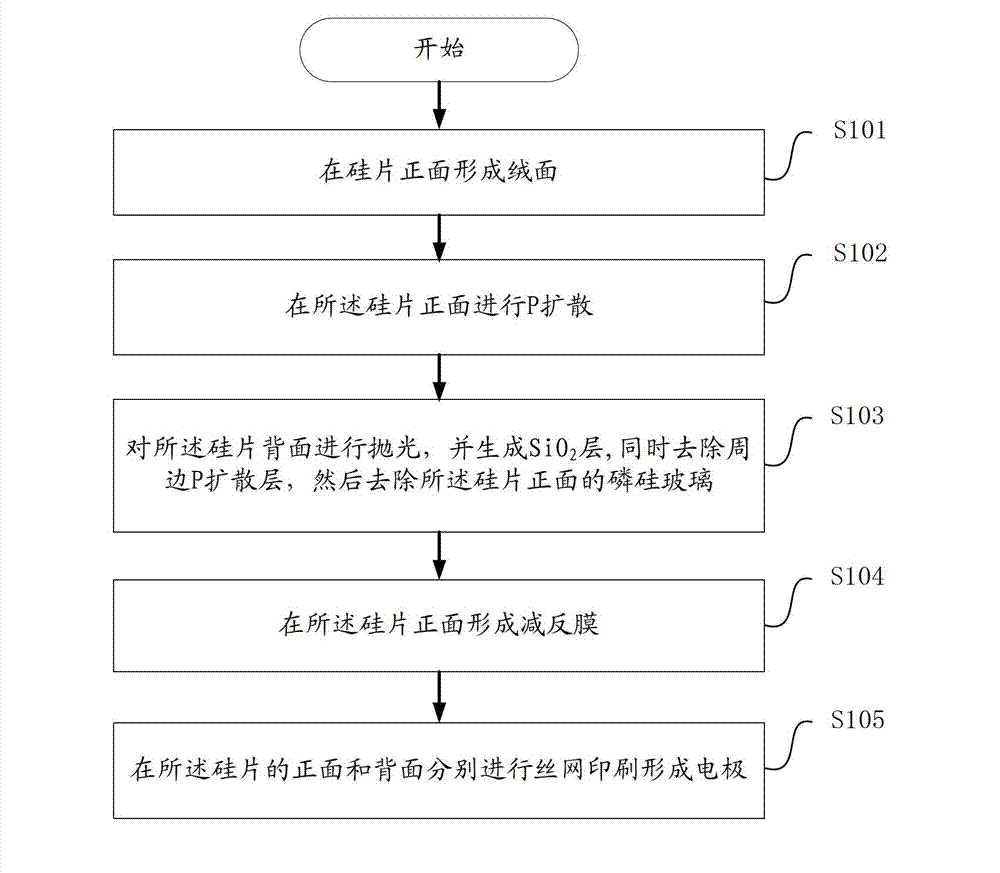

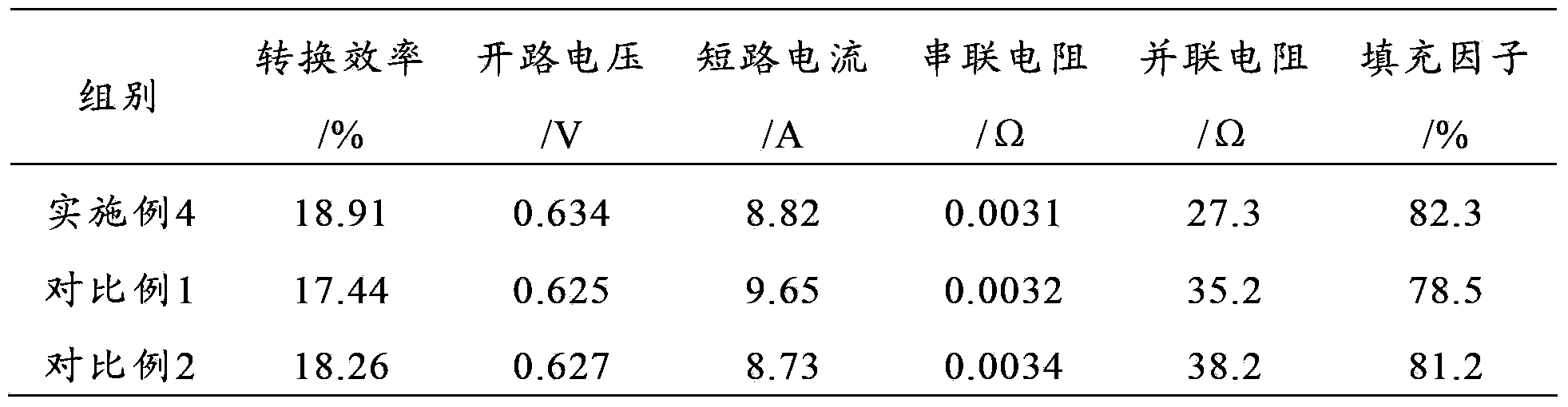

Production method of solar cell

ActiveCN103117330AHas a passivation effectImprove reflectivityRenewable energy productsSemiconductor devicesScreen printingPhotoelectric conversion

The invention discloses a production method of a crystalline silicon solar cell. The production method includes the steps of texturing the front surface of a silicon wafer; performing P diffusion to the front surface of the silicon wafer, polishing the back of the silicon wafer to generate a SiO2 layer, removing the peripheral P diffusion layer, and removing phosphorosilicate glass on the front surface of the silicon wafer; forming a reflection-degreasing film on the front surface of the silicon wafer; and respectively subjecting the front surface and the back of the silicon wafer to silk screen printing to form electrodes. By the use of the production method, the back surface of the silicon wafer can be bright as a mirror, and reflectivity of the back of the silicon wafer is improved effectively. In addition, the smooth back surface allows for formation of evener aluminum back field. The formed SiO2 layer functions in surface passivation, so that minority carrier lifetime can be prolonged. Photoelectric conversion rate of the solar cell produced by the production method can be improved greatly.

Owner:CHINT NEW ENERGY TECH (HAINING) CO LTD

Rust remover and rust-removal method for copper parts

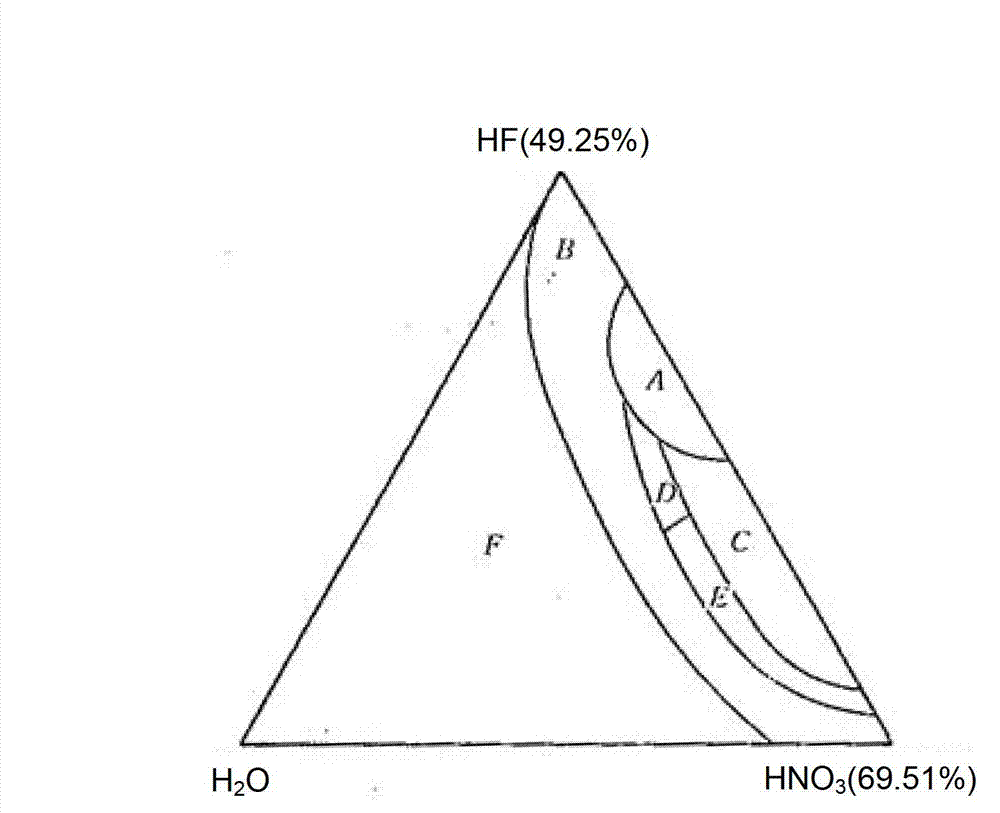

InactiveCN103103544ASurface accuracy has no effectImprove rust removal effectGasolineAqueous solution

The invention relates to a rust remover and a rust-removal method for copper parts. The rust remover is characterized by comprising the following components in percentage by weight: 8 percent of chromic anhydride, 0.3-0.4 percent of sulfuric acid, 0.03 percent of sodium chloride and 90-92 percent of water. The rust-removal method comprises the following steps of: respectively weighing the components according to proportions, sequentially adding the components and uniformly stirring the components; washing the copper parts for oil removal by using gasoline or acetone; soaking the copper parts subjected to oil removal by washing into a rust remover solution prepared from the components in percentage by weight for about 1-2min under the normal temperature; taking the copper parts out of the rust remover solution, immediately rinsing the copper parts by using tap water for 1 minute, and soaking the copper parts into a 2% sodium carbonate water solution for about 2min; and taking the copper parts, rinsing the copper products by using tap water and then wiping the copper parts to dryness. The rust-removal method is simple, has no influence to the surface precision of the copper parts, ensures that the surface subjected to rust removal is glossy and especially has a better dust removal effect on brass parts; the rust remover has an inactivation function; and the treated brass parts are golden yellow.

Owner:徐一达

Doped silicon quantum dot light emitting diode device and preparation method thereof

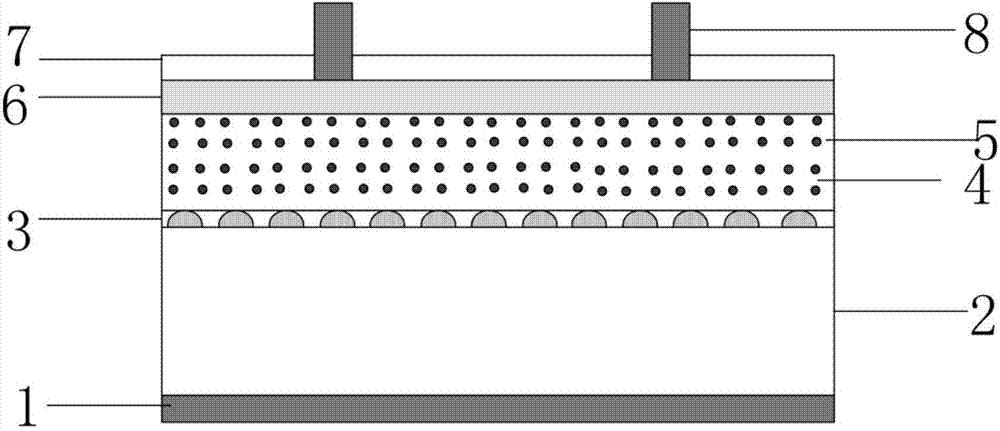

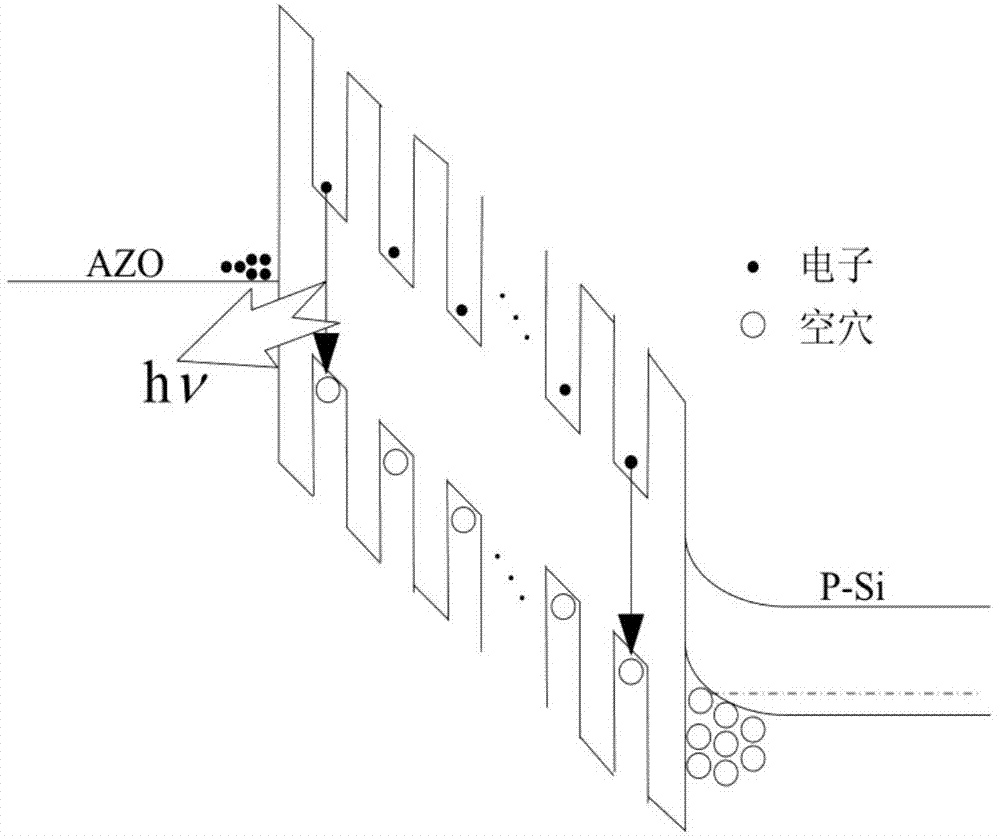

InactiveCN103618037AHas a passivation effectIt has the following beneficial effects: silicon quantum dots embedded in silicon nitride have a passivation effectSemiconductor devicesElectricityElectron hole

The invention discloses a doped silicon quantum dot light emitting diode device which comprises a silicon substrate, a sedimentary silver nanometer particle layer, a plurality of layers of SiNx films, a transparent electricity conducting film AZO layer and an Si3N4 passivation layer. The SiNx films are deposited on a silver nanometer particle structure, are evenly distributed and contain doped silicon quantum dots. The invention further discloses a preparation method of the light emitting diode. The method comprises the steps of utilizing the electroluminescent characteristic of the doped silicon quantum dot-SiNx films to constitute a light emitting active layer of the light emitting diode, and utilizing doping to passivate quantum dots, and enhancing the radiative recombination of an electron hole through a p-n node formed by the doping silicon quantum dot and the silicon substrate. Further, the silver nanometer structure is used for enhancing the strength of electroluminescence, and the doped silicon quantum dot light emitting diode device improves the light emitting efficiency of a light emitting component and is compatible with the traditional CMOS technology.

Owner:HUAZHONG UNIV OF SCI & TECH

Long acting antirust grease

The invention discloses a chemical product, namely long-term antirust grease, which ensures that the production cost is relatively reduced and the antirust time is also prolonged. The effective compositions of the long-term antirust grease comprise machine oil, stearic acid, calcium hydroxide and barium mahogany sulfonate. The operation process of the production technology of the long-term antirust grease is as follows: adding a small amount of machine oil, the stearic acid, the calcium hydroxide and the barium mahogany sulfonate in a reaction kettle first, injecting a certain amount of water, fully saponifying the mixture when the temperature is increased to 130 DEG C, adding remaining machine oil into the reaction kettle, and ensuring that the reaction kettle is subjected to thermal insulation at a temperature of 100 DEG C or so for about 1 hour. The long-term antirust grease can resist from being exposed to the sun and rain; after a metal fastener is coated with the long-term antirust grease, the antirust function is remarkably improved, the antirust performance can reach three years, and the technical problem that the antirust time of old products does not exceed one year is solved; in addition, the long-term antirust grease uses raw materials which are purchased on negotiation, has simple process operation and relatively reduces production cost; and the long-term antirust grease is applicable to the corrosion prevention and lubrication of bolts at various positions such as rail joints, concrete sleepers, railway switches, bridges and so on, and has certain acid, alkali and salt resistance.

Owner:杨小芳

Method for improving rice eating quality and storage period

InactiveCN102972521AGood passivation effectReduce waist burst rateSeed preservation by irradiation/electric treatmentSeed preservation by heatingNutrientHorticulture

The present invention relates to a method for improving rice eating quality and storage period, which is characterized in that: a lactic acid solution is slowly added in a manner of atomization, so that the rice is in a weak-acid and high-humidity environment, low-dose X-ray irradiation is used to activate the enzymes in rice for some time, then hot air and microwave are combined to treat the rice to produce moderate gelatinization, and at the same time the insect enzyme bacteria in the rice are killed. The method can significantly improve the eating quality and the storage period of rice, slow humidification by atomization and low temperature and high humidity retarding treatment can effectively reduce the rice fissuring rate, and the loss of nutrients is reduced.

Owner:NANCHANG UNIV

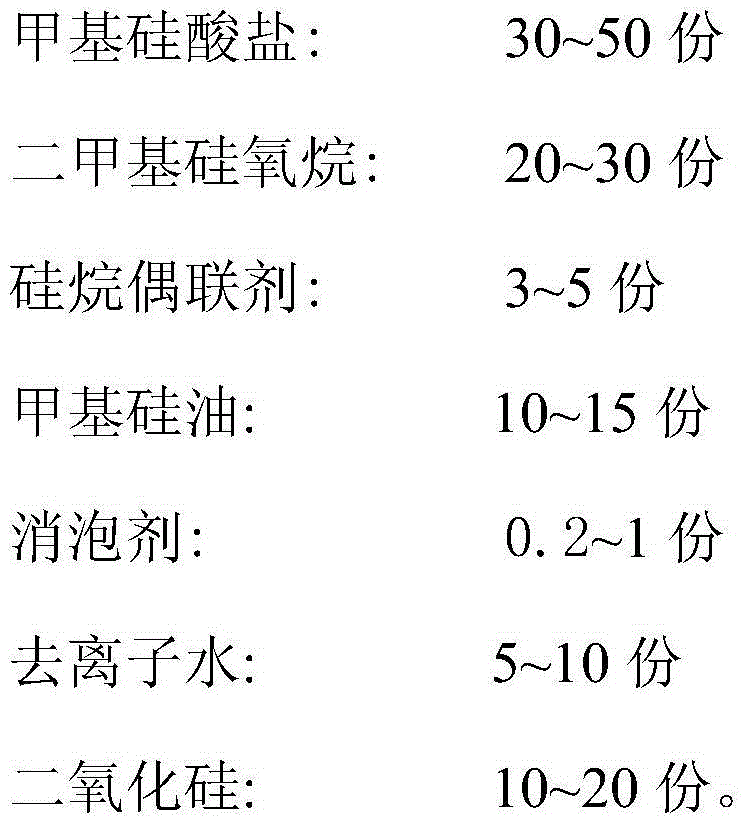

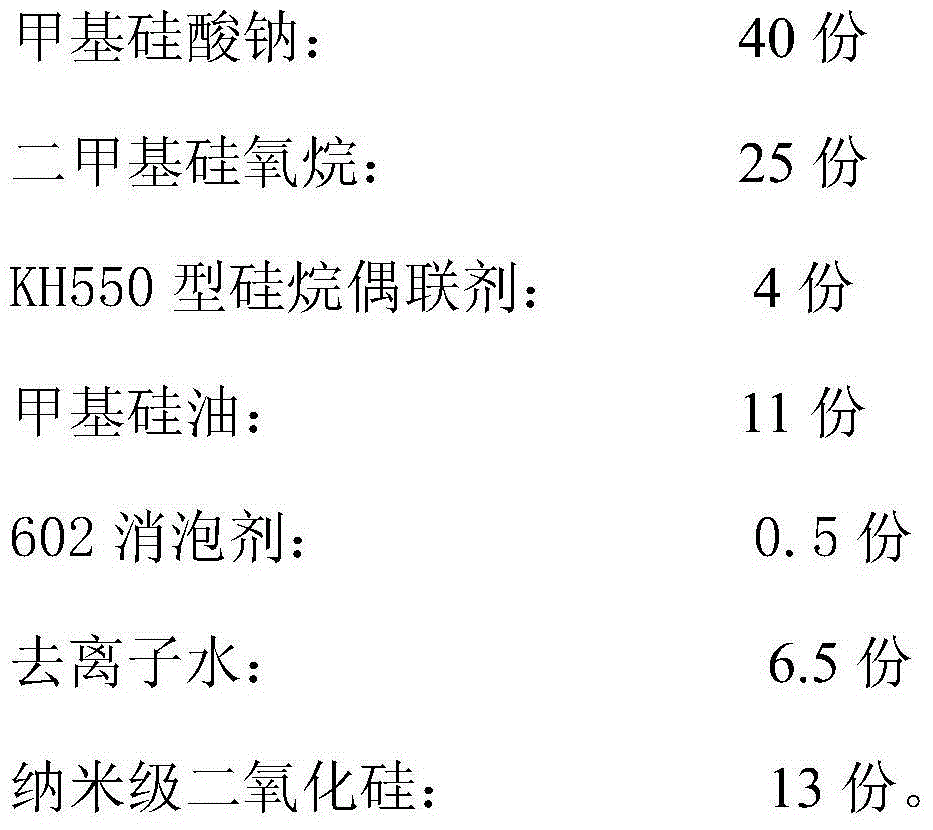

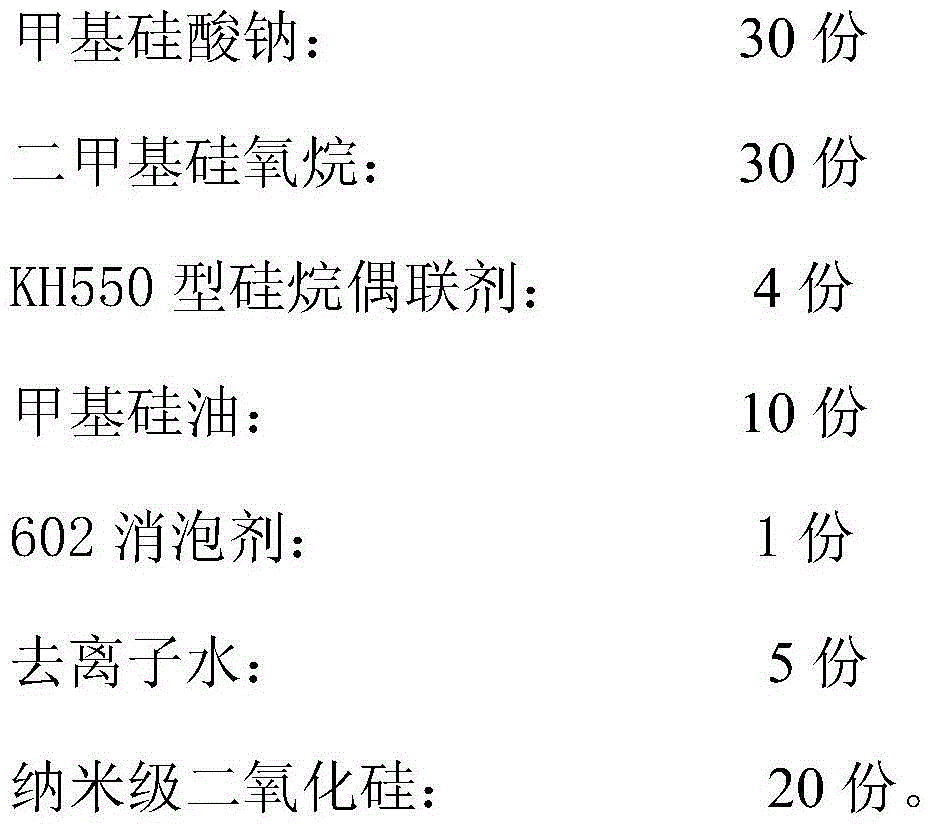

Organosilicon waterproof coating material

The invention discloses an organosilicon waterproof coating material. The organosilicon waterproof coating material is prepared from the following ingredients in parts by weight: 30-50 parts of methyl silicate, 20-30 parts of dimethyl siloxane, 3-5 parts of a silane coupling agent, 10-15 parts of methyl silicone oil, 0.2-1 part of an antifoamer, 5-10 parts of deionized water and 10-20 parts of silicon dioxide. The coating material disclosed by the invention can permeate into a wall by several millimeters and form reticular waterproof films on the surface and interior of the wall so as to improve the waterproof effect, the waterproof films cannot close capillary pores of a base material, and moisture still can spread out from the interior of a wall body, so that waterproof and air-permeable effects are achieved; the coating material is non-toxic, non-combustible, non-explosive, non-volatile, environment-friendly and safe, is free from irritant odors and can be mixed and dissolved with water; the wear resistance is good, and the service life is long; the coating material has a passivating action, is un-rusty to reinforcing steel bars and is wide in range of use; the use is convenient, and the cost is low.

Owner:ZHEJIANG CHUN MING WATERPROOF BUILDING MATERIALS

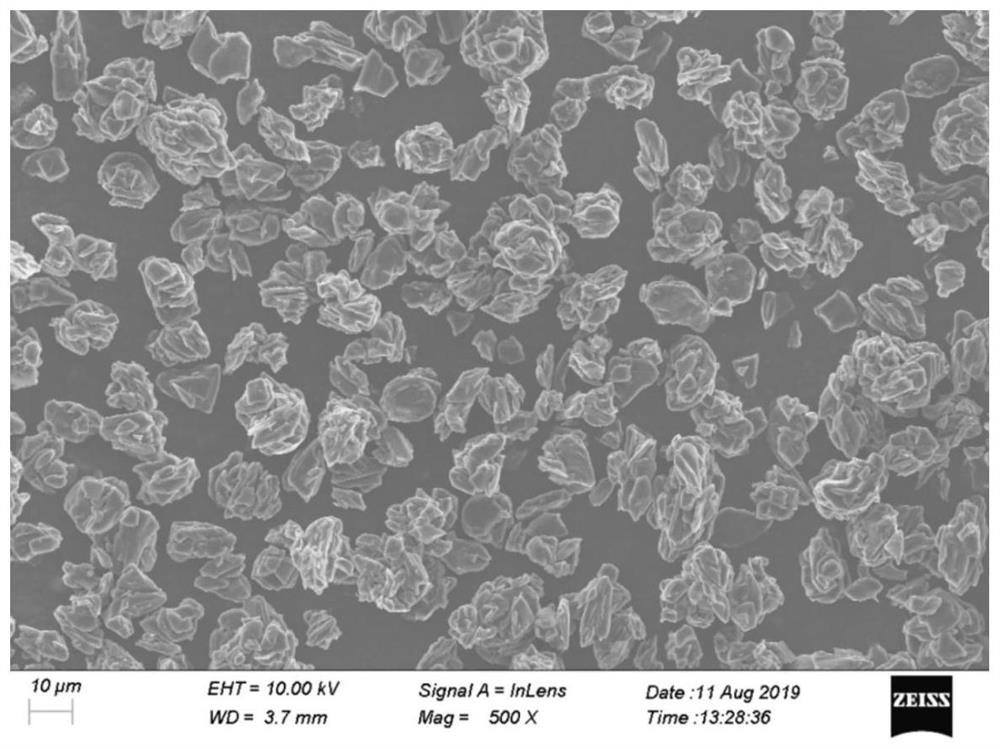

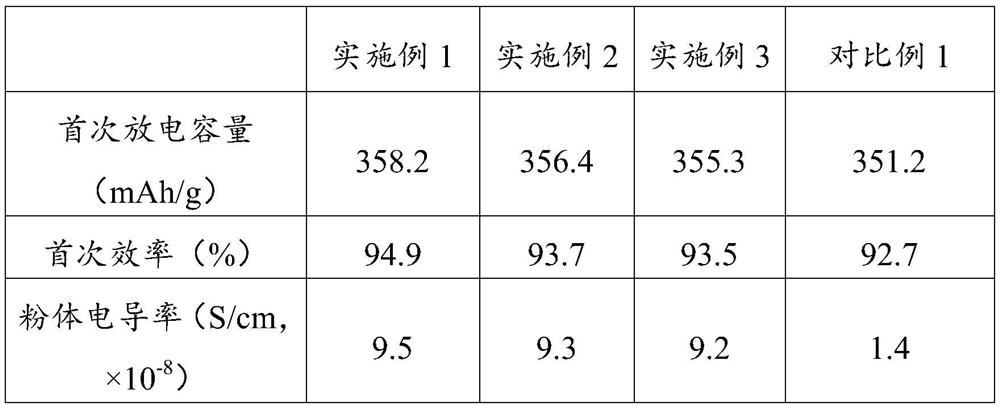

Graphite composite material coated with lithium titanium aluminum phosphate, preparation method of graphite composite material and battery negative electrode

ActiveCN112467117AImprove transmission efficiencyStable structureCell electrodesSecondary cellsTitanium phosphateALUMINUM PHOSPHATE

The invention relates to the field of battery materials and particularly relates to a lithium titanium aluminum phosphate coated graphite composite material, a preparation method thereof and a batterynegative electrode. The lithium titanium aluminum phosphate-coated graphite composite material comprises an inner core and an outer core, wherein the material of the inner core comprises graphite; the inner core is coated with the shell layer, and the material of the shell layer comprises lithium aluminum titanium phosphate and carbon; and the passivation layer is coated outside the shell layer.Graphite is coated with lithium aluminum titanium phosphate and carbon, so conductivity can be improved, the lithium aluminum titanium phosphate has relatively high lithium ion conductivity, the transmission efficiency of lithium ions can be improved, and compared with other materials, the lithium aluminum titanium phosphate has the characteristics of stable structure, strong chemical stability, good cycle performance and the like. The passivation layer has a passivation effect on the lithium aluminum titanium phosphate, reduces the side reaction of the lithium aluminum titanium phosphate, andimproves the storage performance and cycle performance of the lithium aluminum titanium phosphate, thereby improving the lithium ion transmission efficiency, rate capability and safety performance ofthe graphite composite material coated with the lithium aluminum titanium phosphate.

Owner:HUNAN SHINZOOM TECH

Heavy metal contaminated farmland soil remediation agent, preparation method thereof and remediation method thereof

InactiveCN110982536AStable passivationImprove fertilityCalcareous fertilisersClimate change adaptationSlagCarbonization

The invention provides a heavy metal contaminated farmland soil remediation agent. The heavy metal contaminated farmland soil remediation agent is prepared from, by weight, 10-25 parts of medical stone powder, 15-27 parts of carbonized rice husks, 10-25 parts of steel slag powder, 10-20 parts of weathered coal, 10-25 parts of lime, 10-25 parts of white carbon black and 12-24 parts of organic fertilizer. The heavy metal contaminated farmland soil remediation agent is applied to a soil surface of a heavy metal contaminated farmland and evenly mixed with soil, the soil moisture is kept to reach the maximum field water-holding capacity, and crops can be planted 5-8 days after balance. Heavy metals in the soil are quickly, efficiently and stably passivated through multiple modes such as combined precipitation, adsorption, complexing and acid-base buffering, the activity of the heavy metals in the soil is reduced, the passivated heavy metals are prevented from being activated again, and theeffect of finally reducing the activity of the heavy metals in the farmland soil is achieved.

Owner:纳琦绿能工程有限公司

Stop protection agent and stop protection method for waste heat boiler of gas turbine power plant

The invention relates to a stop protection agent and a stop protection method for the waste heat boiler of a gas turbine power plant. The stop protection agent for the waste heat boiler of the gas turbine power plant comprises water, carbohydrazide used for reducing dissolved oxygen in water and promoting the formation of a complete compact protection film on a metal surface, ammonia water used for adjusting the pH value, and imidazoline-ammonium-salt, wherein the concentration of carbohydrazide is 300-400mg / L, and the concentration of imidazoline-ammonium-salt is 100-200mg / L; the pH value of the stop protection agent is 9.5-10.0. The stop protection method for the waste heat boiler of the gas turbine power plant comprises the following steps of: 1 hour before slide stop, stopping adding phosphate, adding carbohydrazide until the concentration of carbohydrazide is 300-400mg / L, adjusting the pH value to 9.5-10.0 by using ammonia water, and uniformly circulating; when the temperature of main steam is lowered to be below 300 DEG C, adding imidazoline-ammonium-salt in a system, and circulating for more than half an hour. The stop protection agent is good in preservative effect, non-toxic, safe and environment-friendly.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

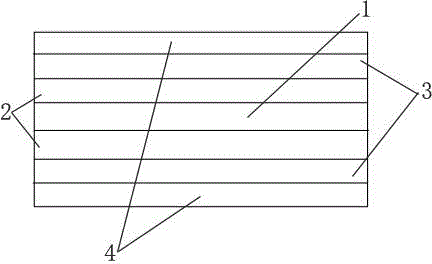

Marine component protective coating and construction method thereof

InactiveCN104085158AImprove performanceReduced shieldingSynthetic resin layered productsElectrolytic organic material coatingSurface layerPolypyrrole

The invention discloses a marine component protective coating and a construction method thereof. The protective coating has a three-layer structure, wherein the bottom layer is a polypyrrole thin film which is polymerized on the surface of a steel component via an electrochemical method; the middle layer is an epoxy coating; the surface layer is one of polyurethane acrylate coating, epoxy acrylate coating and polyurea coating. The construction method comprises the steps of polishing a workpiece, then polymerizing the polypyrrole thin film on the surface at constant potential and sequentially coating the workpiece with the epoxy coating and the surface layer. The marine component protective coating has favorable binding force, is excellent in rotproofness and weather fastness, is long in service life in marine environment and can be applied to the long-acting protection of marine components.

Owner:南通河海大学海洋与近海工程研究院 +1

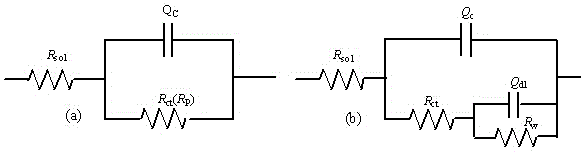

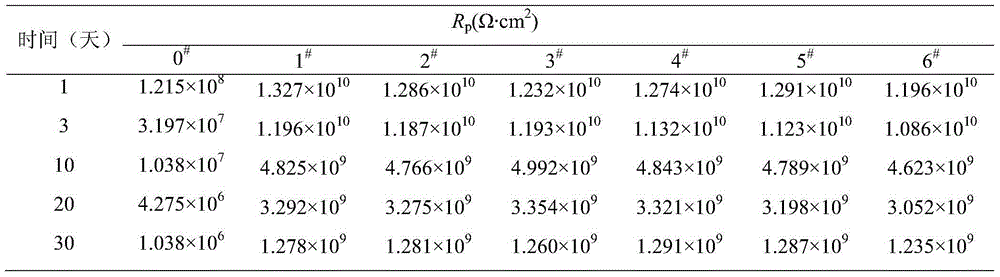

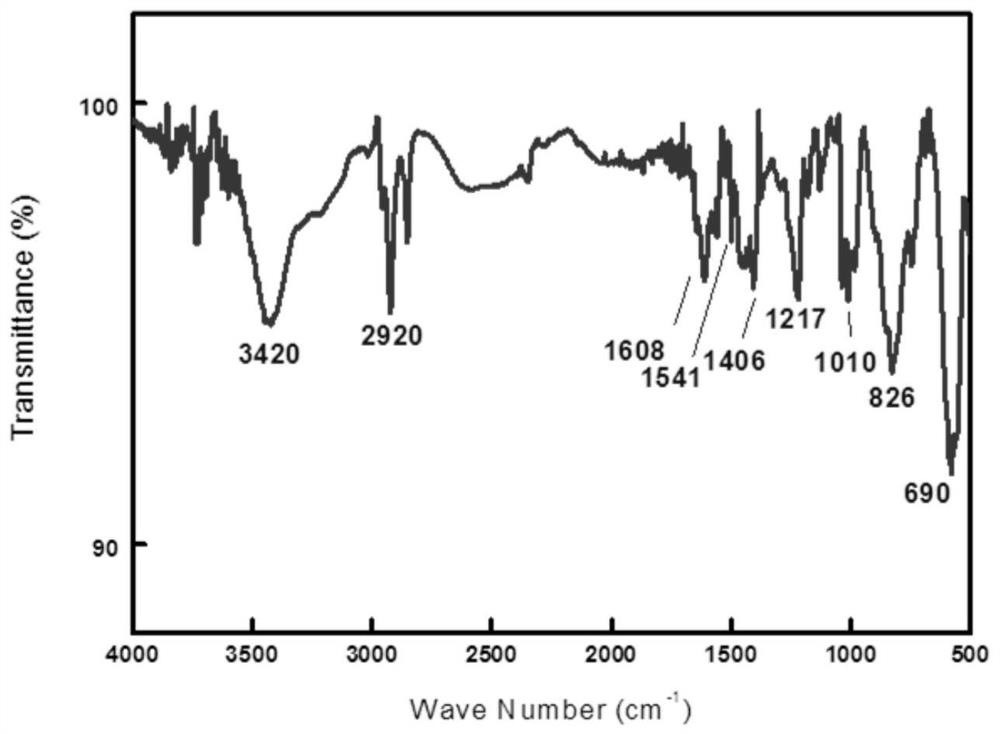

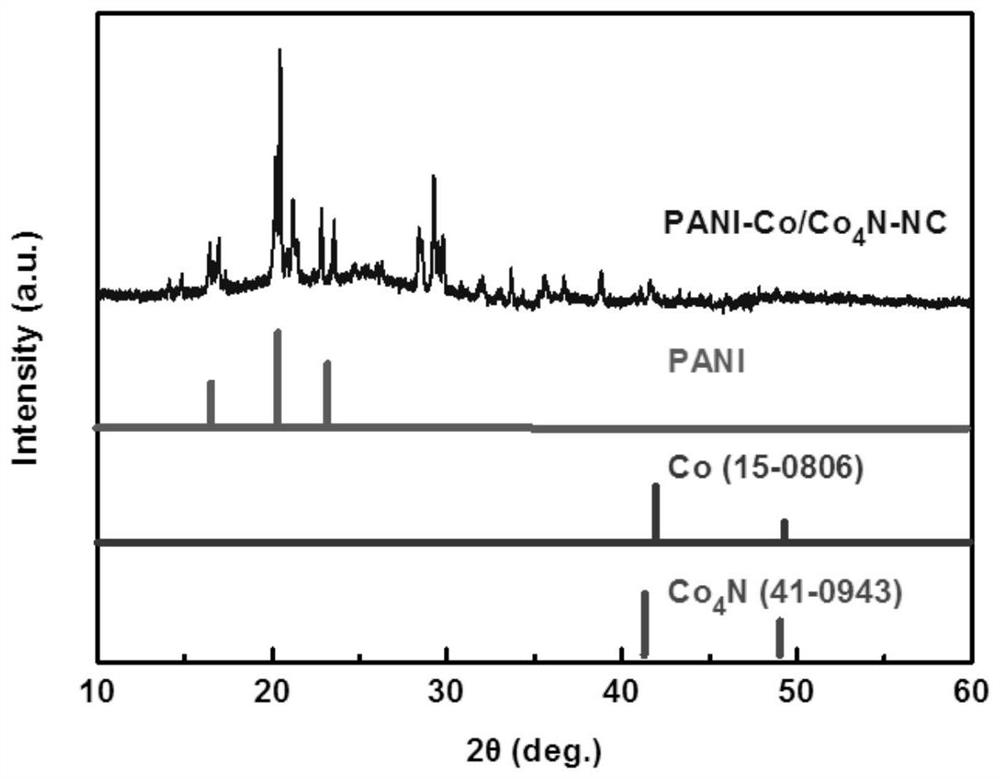

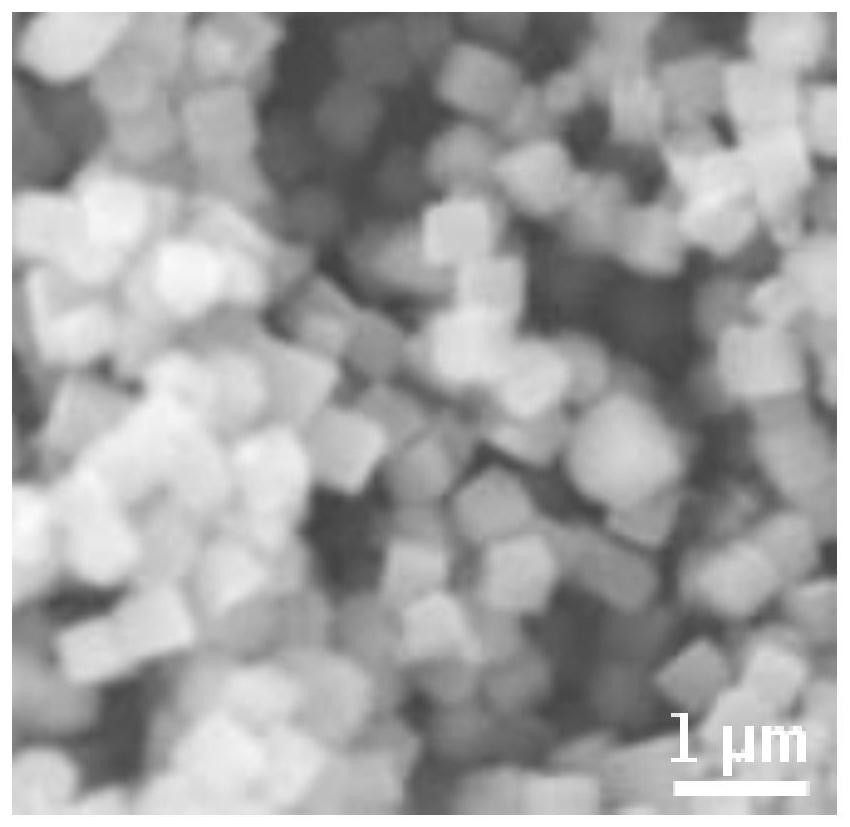

Polyaniline/MOF composite coating electrode material as well as preparation method and application thereof

ActiveCN112500760AHas a barrier effectHas a passivation effectAnti-corrosive paintsEpoxy resin coatingsEpoxyCoated electrodes

The invention provides a polyaniline / MOF composite coating electrode material and a preparation method and application thereof. The coating electrode material is formed by combining a component A, a component B and a component C according to the mass ratio of m(component A) to m (component B) to m(component C) being (1.5-2.5):(1-5):(800-1200). The component A is polyaniline (PANI), the component Bis an MOF structural material (Co / Co4N-N), and the component C is epoxy resin. According to the preparation method, the polyaniline material is modified by doping the MOF structure material, so thatthe electrochemical performance of the polyaniline material is improved, and then the epoxy resin base material is modified by utilizing the modified polyaniline material. The Q235 steel is taken as aresearch object, so that the corrosion protection performance of the epoxy resin base material is improved, and the corrosion resistance of the Q235 steel in a corrosion environment is effectively improved. A process route achieving the best performance is obtained by carrying out experimental exploration on a key material part.

Owner:OCEAN UNIV OF CHINA

Solar cell antireflection film and manufacturing method thereof

InactiveCN104241402AHas a passivation effectImprove passivation effectFinal product manufacturePhotovoltaic energy generationCrystalline siliconSilicon nitride

The invention provides a solar cell antireflection film. The solar cell antireflection film is composed of a non-crystalline silicon layer, a first silicon nitride film and a second silicon nitride film, wherein the non-crystalline silicon layer, the first silicon nitride film and the second silicon nitride film are stacked in sequence. The non-crystalline silicon layer is arranged on the surface of a solar cell silicon wafer. The invention further provides a manufacturing method of the solar cell antireflection film. In the manufacturing process of the antireflection film, the non-crystalline silicon layer, the first silicon nitride film and the second silicon nitride film are deposited on the surface of the solar cell silicon wafer with a plasma enhanced vapor deposition method. The solar cell antireflection film has both the inactivation function and the antireflection function, and therefore the conversion efficiency of a solar cell can be improved easily.

Owner:JINKO SOLAR CO LTD +1

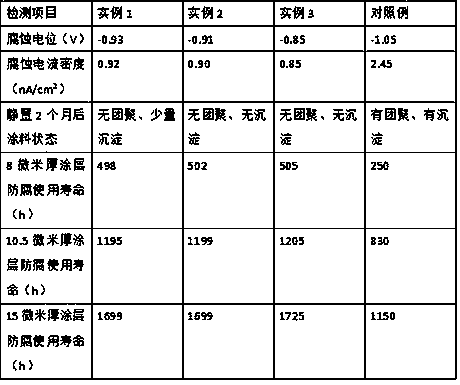

Preparation method of carbon-based metal anticorrosive paint

InactiveCN108485451AIncrease the number of poresAvoid the defects of easy agglomeration and precipitationAnti-corrosive paintsChemistryCarbon chain

The invention relates to a preparation method of carbon-based metal anticorrosive paint, which belongs to the technical field of paint preparation. The shaddock peel with a loose porous structure is used as a raw material and mixed with biogas slurry and metal salt solution after being crushed, finally the mixture is mildewed at a high temperature and high humidity condition, then a mildewed product is carbonized and reacts with long-carbon-chain alkyl acyl chloride to obtain a pre-modified charcoal, finally the pre-modified charcoal is finally modified by utilizing microorganisms and grease to obtain modified biological porous carbon, and the modified biological porous carbon is used as filler to be mixed with other raw materials, so that the carbon-based metal anticorrosive paint is finally obtained. According to the carbon-based anticorrosive paint prepared by the invention, the compatibility between the carbon-based filler and the paint matrix is good, no clustering precipitate iseasy to generate, the anticorrosive effect is excellent, and the application prospect is wide.

Owner:郦璋

Composite microbial soil remediation agent and preparation method thereof

PendingCN114409445AHas a passivation effectReduce contentAgriculture tools and machinesBio-organic fraction processingBacillus licheniformisMicrobial agent

The invention discloses a composite microbial soil remediation agent and a preparation method thereof. The composite microbial soil remediation agent is prepared from the following raw materials in parts by weight: 10-18 parts of a composite microbial agent, 30-70 parts of organic matters and 10-25 parts of inorganic raw materials, the compound microorganisms are prepared from the following microorganisms in parts by weight: 0.5 to 5 parts of bacillus subtilis, 0.5 to 5 parts of bacillus licheniformis, 0.3 to 4 parts of bacillus mucilaginosus, 0.2 to 3 parts of bacillus megaterium and 0.2 to 3 parts of purpureocillium lilacinum; the organic matter is crop waste; the inorganic raw material is a mixture of sepiolite, medical stone and apatite; the compound microorganism soil remediation agent has a good heavy metal contaminated soil remediation effect and has a remarkable effect in the aspects of improving the physical and chemical properties of soil and remediating soil pollution, the remediation rate of the heavy metal contaminated soil reaches 50% or above, and the yield of crops can be remarkably increased.

Owner:春华秋实科技集团有限公司

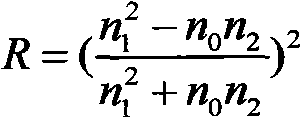

Multi-layered anti-reflecting film for solar cells

InactiveCN104659118AHas a passivation effectSimple preparation processSemiconductor devicesRefractive indexSolar cell

The invention discloses a multi-layered anti-reflecting film for solar cells. The multi-layered anti-reflecting film comprises a solar cell layer, wherein SiO2 films are arranged onto and beneath a cell window layer; anti-reflecting films are arranged on the SiO2 films arranged onto and beneath the cell window layer; the thickness of the SiO2 films is 3-60 nm; the anti-reflecting films are transmitting films with the thickness of 30-120 nm and the reflection rate of 2.3-2.5. The multi-layered anti-reflecting film can seek the novel technical approach to replace the conventional SiNx single-layered anti-reflecting film commonly used in industry; by adopting the multi-layered film structure, optical matching and the electrical passivation effect can be realized, the anti-reflecting passivation effect of the multi-layered film structure is similar to that of the SiNx single-layered anti-reflecting film; besides, the multi-layered film structure is simple in preparation technology and low in equipment cost, and is a relatively ideal structure; furthermore, the multi-layered film structure is a composite structure with an upper structure and a lower structure which are the same, so that the passivation effect and the anti-reflecting effect are improved.

Owner:WUXI SAIJING SOLAR

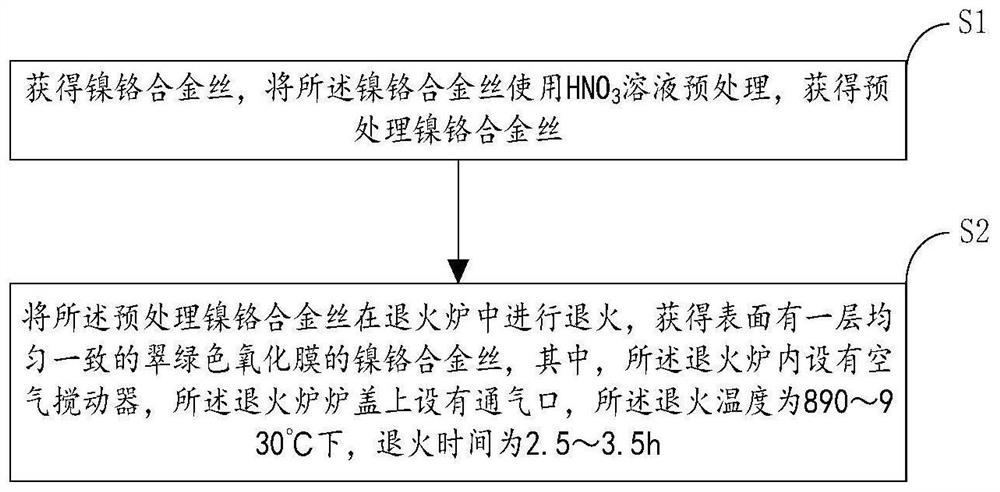

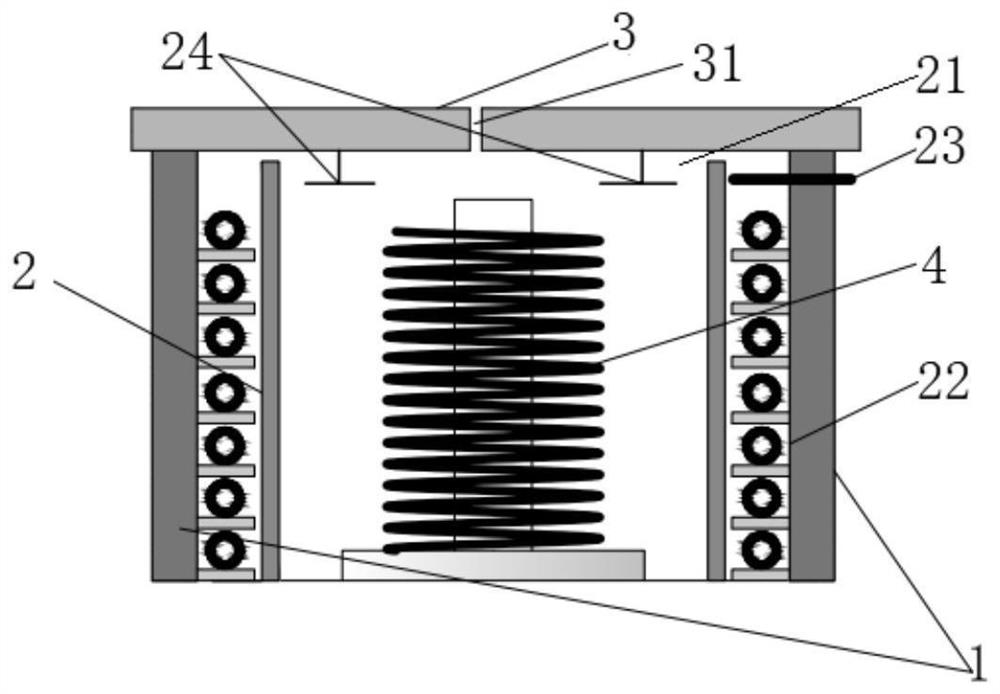

Surface treatment method and device for nickel-chromium alloy wire

ActiveCN112080749AHigh chemical potentialReduce the formation temperatureSolid state diffusion coatingNickel chromium alloyNichrome

The invention discloses a surface treatment method for a nickel-chromium alloy wire. The surface treatment method comprises the steps of obtaining the nickel-chromium alloy wire, and pretreating the nickel-chromium alloy wire with an HNO3 solution to obtain a pretreated nickel-chromium alloy wire; and annealing the pretreated nickel-chromium alloy wire in an annealing furnace to obtain the nickel-chromium alloy wire with a uniform, consistent emerald green oxide film on the surface, specifically, an air agitator is arranged in the annealing furnace, an air vent is formed in a furnace cover ofthe annealing furnace, the annealing temperature is 890-930 DEG C, and the annealing time is 2.5-3.5 hours. According to the surface treatment method, the nickel-chromium alloy wire with the uniform,consistent emerald green oxide film on the surface can be obtained, the oxidation color of the nickel-chromium alloy wire is uniform and stable, the color is emerald green, the requirements of customers are met to the greatest extent, and the surface treatment method is very helpful for improving the quality of the product.

Owner:BEIJING SHOUGANG GITANE NEW MATERIALS

Glass flake-based anticorrosive pigment and preparation method thereof

ActiveCN106280550AGood compatibilityGood dispersionAnti-corrosive paintsPigment treatment with macromolecular organic compoundsDispersitySlurry

The invention belongs to the technical field of anticorrosive pigments, and relates to a glass flake-based anticorrosive pigment and a preparation method thereof. The preparation method comprises the steps that glass flakes are added into hydrochloric acid for acid treatment, and filtering and washing are conducted to obtain acid-treated glass flake filter cakes; the acid-treated glass flake filter cakes are added into deionized water, stirring is conducted for 30 min, the liquid is heated to constant temperature, the pH value is regulated, a ferric trichloride solution and a sodium hydroxide solution are dropwise added under the constant-temperature stirring condition simultaneously, after dropwise adding is completed, reacting by stirring is conducted for 1-4 h, and glass flake iron oxide slurry is obtained; the glass flake iron oxide slurry is cooled to constant temperature, anline is added, stirring is conducted for a period of time at constant temperature, then an ammonium persulfate solution is added, reacting by stirring is conducted, suction filtration is conducted, washing is conducted with deionized water until filtrate is colorless, polyaniline outer membrane glass flake iron oxide filter cakes are obtained, drying is conducted, and the finished product is obtained. Accordingly, the dispersity of the anticorrosive pigment in resin can be improved, the anticorrosive property is enhanced, and priming paint does not need to be applied.

Owner:ZHEJIANG COLORAY TECH DEV

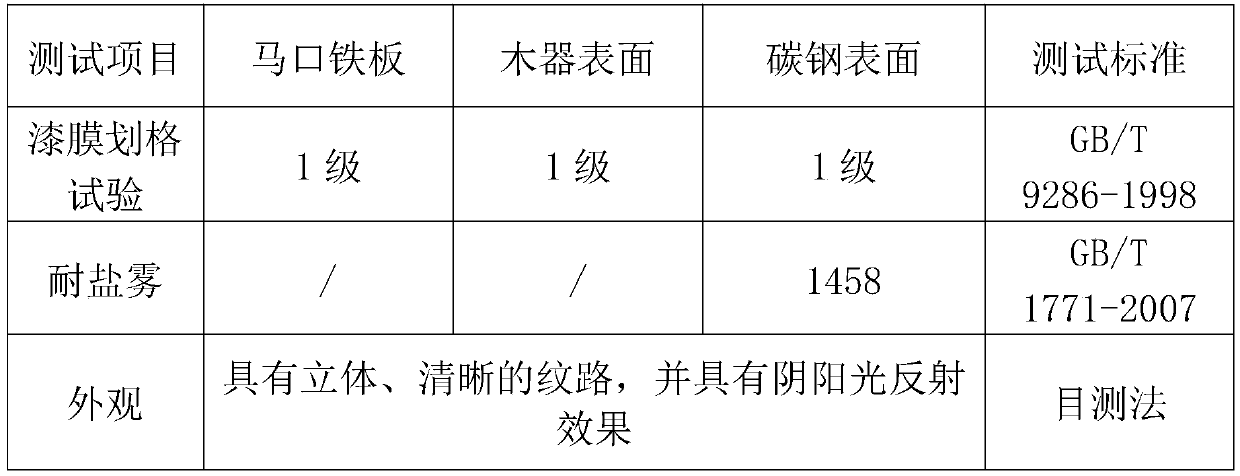

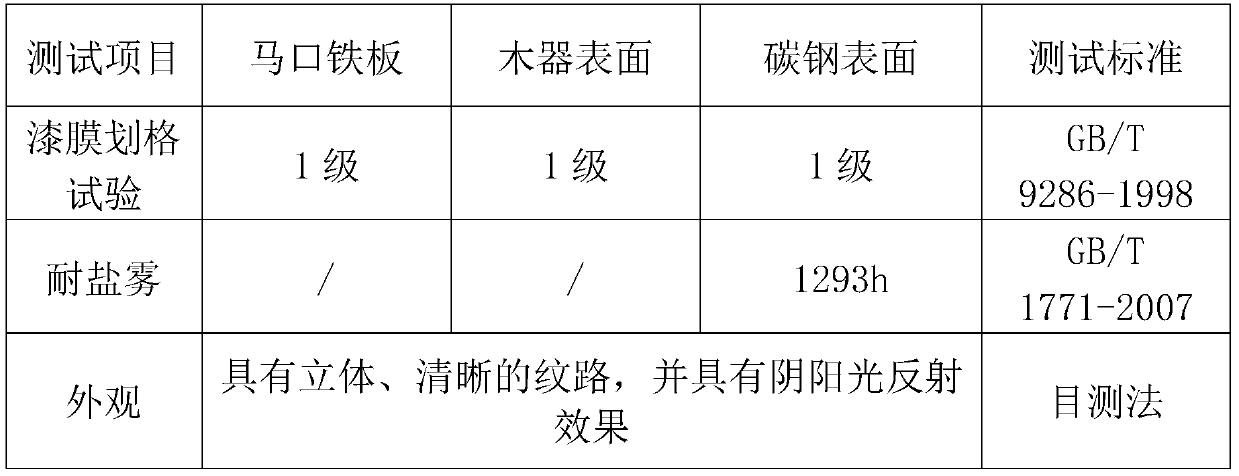

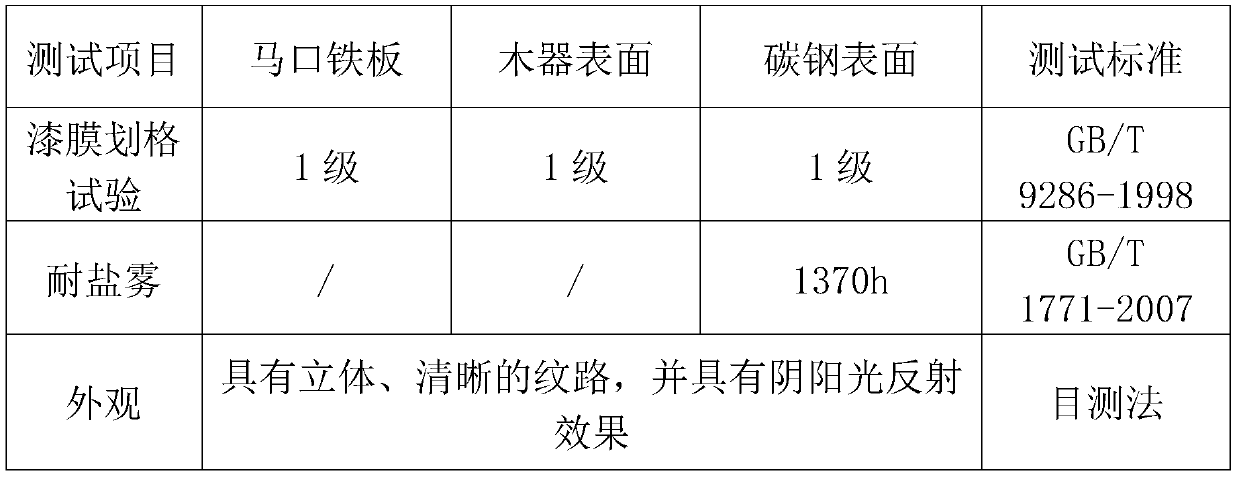

Corrosion-resistant water-based foliar texture effect paint as well as preparation and construction methods thereof

ActiveCN110305561AImprove anti-corrosion performanceGood anti-corrosion functionAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention relates to the technical field of water-based coatings, provides a corrosion-resistant water-based foliar texture effect paint as well as preparation and construction methods thereof andsolves the problem that a solvent coating in the art results in environment pollution and human health hazards and has great potential safety hazards in a production process. The corrosion-resistantwater-based foliar texture effect paint is composed of a component A and a component B, wherein the component A comprises the following ingredients in percentage by mass: 40-50% of water-based epoxy resin, 0-3% of film forming additives, 0-5% of epoxy diluent, 0-2% of defoaming agent I, 0-1% of oil-based bentonite, 0-2% of dispersing agent, 30-50% of cement and 0-20% of pigments and fillers; and the component B comprises the following components in percentage by mass: 50-60% of water-based curing agent, 30-40% of water, 0-1% of water-based bentonite, 0-1% of defoaming agent II, 0-1% of water-based wetting agent, 2-4% of film forming additives, 0-5% of antirust additives and 0-10% of water-based color paste.

Owner:XINHE NEW MATERIALS CO LTD

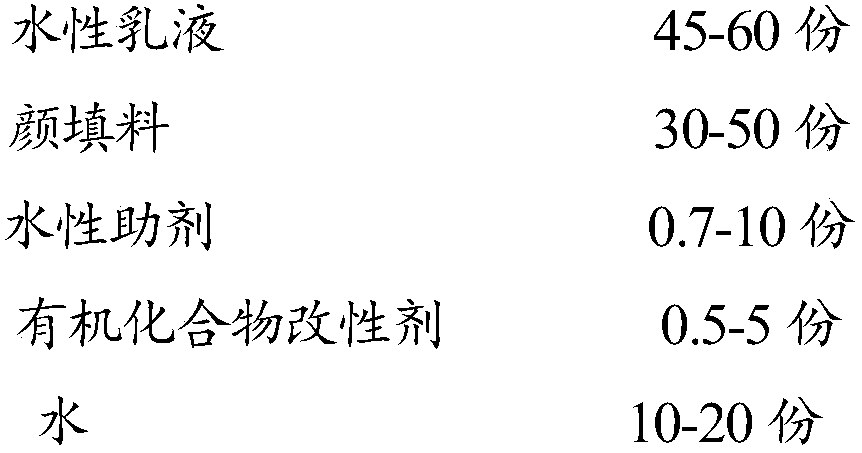

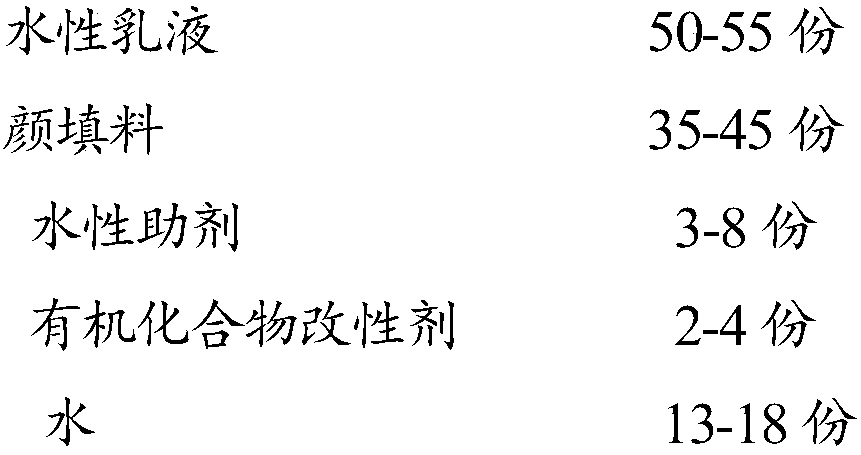

Modified environment-friendly waterborne anticorrosion coating and preparation method thereof

ActiveCN108410277ARealize multiple modificationWith sustained releaseAnti-corrosive paintsChemical LinkageEmulsion

The invention relates to a modified environment-friendly waterborne anticorrosion coating and a preparation method thereof, and belongs to the field of waterborne propylene anticorrosion coatings. Thecoating comprises waterborne emulsion and an organic compound modifying agent, and the organic compound modifying agent is at least one of organic amine, an organic amine derivative, organic phosphine and an organic phosphine derivative. According to the coating, a chemical bond is formed through other components such as strongly polar groups in the organic compound modifying agent, base materials, pigments and fillers and film forming matters, multiple modification of the base materials, the pigments, the fillers and the film forming matters is achieved, the coating has slow-release and passivation functions of inorganic rust-proof pigments and further has a shielding function absented by the inorganic rust-proof pigments, the coating has a long-term multiple anticorrosion function, theadhesive force of the coating reaches a level 0, optimal salt fog resistance cannot generate bubble and get rusty for 1000 hours or more, and optimal salt water resistance cannot generate bubble and get rusty for 600 hours or more.

Owner:GUANGZHOU JOINTAS CHEM

Method for grafting and cultivating cucumbers

InactiveCN107347463AImprove resistance to pests and diseasesEnhance resiliencePlant growth regulatorsBiocideAbamectinGrowth promoting

The invention discloses a cucumber grafting cultivation method, which is characterized in that it includes the following aspects: (1) seed detoxification, mixing cucumber and loofah seeds, and using abamectin solution to carry out atomization detoxification treatment; (2) For storage, add ethanol to the selenium-enriched fermentation liquid, put the seeds in and store them at low temperature for 8-10 days, and then carry out germination treatment; (3) For seedling cultivation, mix loess and organic fertilizer to lay seedling boxes, adjust the seedlings after sowing Indoor carbon dioxide and pressure for cultivation; (4) Grafting, cucumber seedlings and loofah seedlings are grafted when they grow to 4-6 true leaves, the incision is soaked in a growth-promoting agent, and the incision is wrapped after docking; (5) Daily management, regular use The growth-promoting agent and the selenium-enriched fermentation liquid are sprayed and watered on the cucumber grafted plants, and the cultivation temperature is adjusted, and the seedlings are raised about 20 days after grafting and then transplanted.

Owner:宁国市绿缘蔬菜种植专业合作社

Method for preparing environment-friendly type anti-corrosive and anti-fingerprint metal surface coating

InactiveCN101392142BCorrosion resistanceHas a passivation effectPretreated surfacesAnti-corrosive paintsEpoxyMicrocrystalline wax

The invention relates to a composition for protecting metal surfaces, in particular to a preparation method of an environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. The composition contains an A component and a B component, the A component takes waterborne epoxy resin as a matrix resin and nano-silica, a silane coupling agent, microcrystalline wax disperse liquid, zirconium complex, deionized water, defoamer and a levelling agent are added, thus obtaining the A component; the B component contains a waterborne epoxy modified amine curing agent and a certain quantity of epoxy curing promoter. The two components are mixed and stirred evenly at a ratio of 4:1 to 3:1 to form the environmentally friendly anticorrosive fingerprint resistant paint for metal surfaces. After coating, metal can be heated by going through a baking channel at a certain temperature, the film forming time can be controlled by adjusting the heating period and finally a transparent coating layer which has quite good anticorrosive protection function over metal and fingerprint resistant function is formed.

Owner:TONGJI UNIV

A kind of pesticide slow-release rate-control film and preparation method thereof

ActiveCN104798773BLong release periodProlong duration of drug effectBiocidePlant growth regulatorsMAGNESIUM AMINO ACID CHELATEAdditive ingredient

The invention discloses a pesticide slow release speed-control film and a preparing method thereof, and belongs to the technical field of agricultural production. The pesticide slow release speed-control film comprises the following recipe ingredients in parts by weight: 1 to 50 parts of curing agents, 1 to 5 parts of inner replacing agents, 0.1 to 5 parts of one-way infiltrating films, 0.1 to 5 parts of bridge connecting agents, 0.2 to 5 parts of magnesium amino acid chelate and 1.5 to 2.5 parts of water. The preparing method comprises the following steps that a substance A is obtained after the curing agents, the bridge connecting agents and the water are mixed; the inner replacing agents are added into the substance A in different times, and stirring is carried out; a substance B is obtained; the substance B is subjected to temperature reducing treatment, then, the one-way infiltrating films are added, and a substance C is obtained; the substance C is subjected to temperature reducing processing, then, the magnesium amino acid chelate is added, the temperature reduction is carried out again, and finished products are obtained. The pesticide slow release speed-control film and the preparing method have the characteristics that the pesticide effect continuing period is obviously prolonged, the cost investment is reduced, the release uniformity of pesticide effective ingredients is improved, the applicability is high, and the application field is wide.

Owner:青岛海纳生物科技有限公司

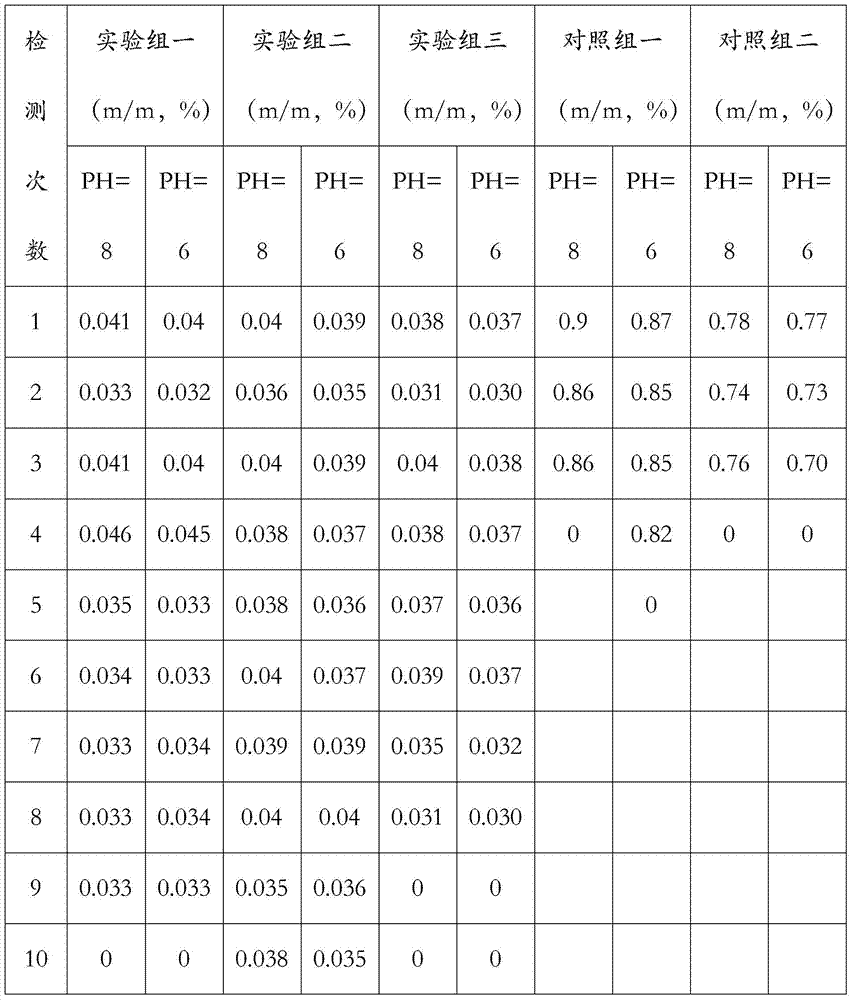

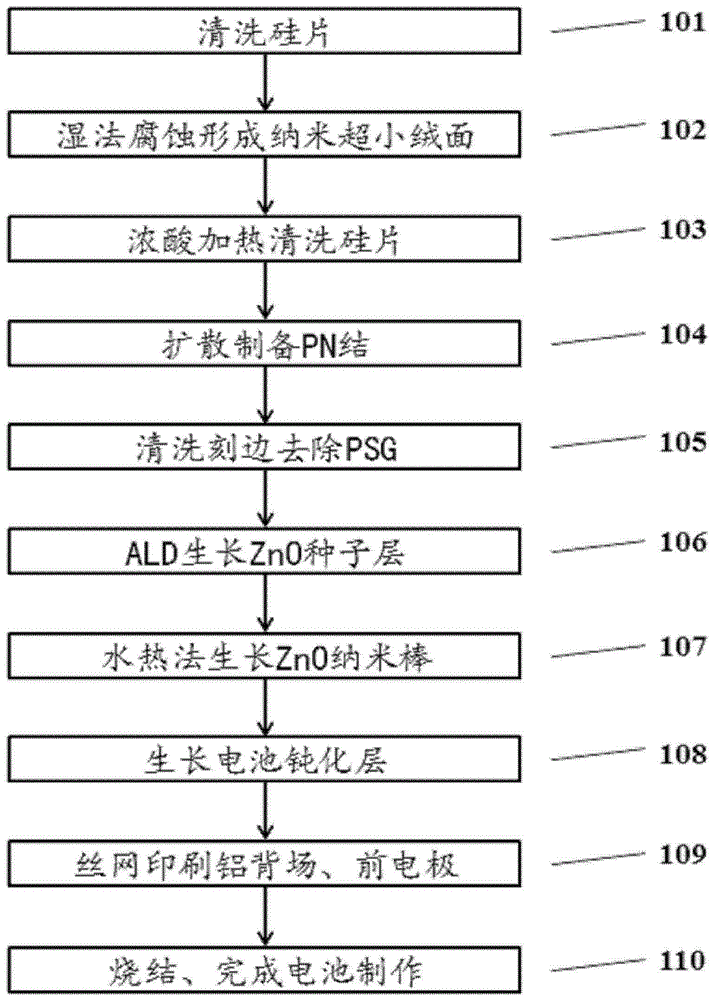

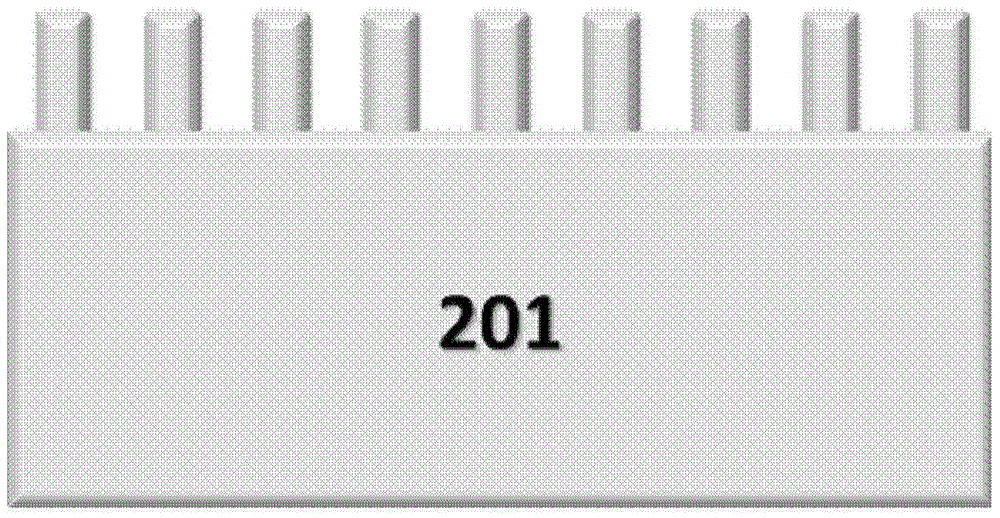

An ultra-small textured solar cell combined with zinc oxide nanostructure and its preparation method

ActiveCN104465814BReduce reflectivityPromote absorptionPhotovoltaic energy generationSemiconductor devicesMicro nanoSilver paste

The invention discloses a super-small suede solar cell combined with a zinc oxide nanostructure and a preparation method of the super-small suede solar cell combined with the zinc oxide nanostructure. The solar cell comprises a silicon wafer, a PN junction, the zinc oxide nanostructure, a passivation layer, silver paste and aluminum paste, wherein the surface of the silicon wafer is provided with super-small suede; the PN junction is formed at the position, close to the nanometer super-small suede structure, of the silicon wafer; the zinc oxide nanostructure grows in the surface and gaps of the super-small suede; the passivation layer is arranged on the side, provided with the super-small suede, of the silicon wafer; the silver paste is arranged on the side, provided with the super-small suede, of the silicon wafer to form a front electrode of the solar cell; the aluminum paste is arranged on the side, not provided with the super-small suede, of the silicon wafer to form a back electrode of the solar cell. According to the super-small suede solar cell, through combination with zinc oxide nanorods, absorption of photons at a short waveband can be further enhanced. Besides, since the gaps of the silicon-based micro-nano structure are filled with zinc oxide, on one hand, the electrode contact area is effectively increased, and good electrode contact is formed; on the other hand, transverse carrier transportation of the super-small suede cell can be enhanced, and meanwhile a certain passivation effect is achieved. The efficiency of the silicon-based nanostructure solar cell is effectively improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com