Polyaniline/MOF composite coating electrode material as well as preparation method and application thereof

A composite coating and electrode material technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of poor metal structure adhesion, limited PANI application, low solubility, etc., to improve performance, wide application and Market value, effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A kind of polyaniline / MOF composite coating electrode material of the present invention, is synthesized by A component, B component, C component;

[0079] Specific steps are as follows:

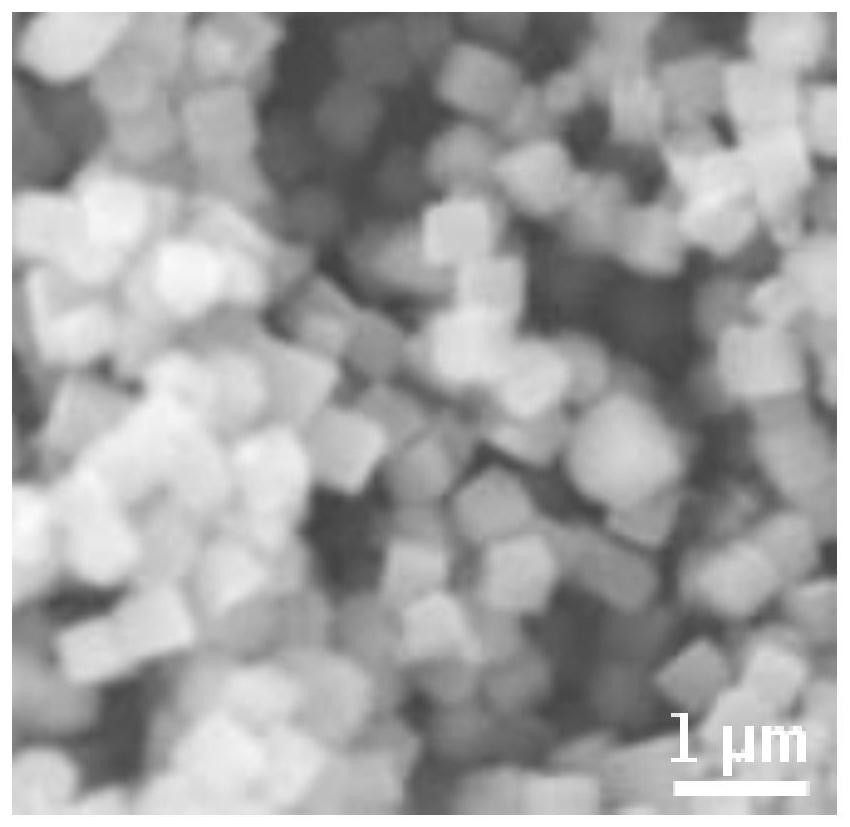

[0080] 1) Synthesis of component B: Dissolve 1160mg Co(NO 3 ) 2 ·6H 2 0 and 20mg CTAB, and stirred rapidly; the above solution was quickly dissolved in a mixed solution composed of 18160mg 2-methylimidazole and 280mL deionized water, and vigorously stirred at room temperature for 6h; the precipitate was centrifuged and washed with ethanol 3 times to clarification; The material was placed in a vacuum oven for 12 hours to obtain a ZIF-67 precursor.

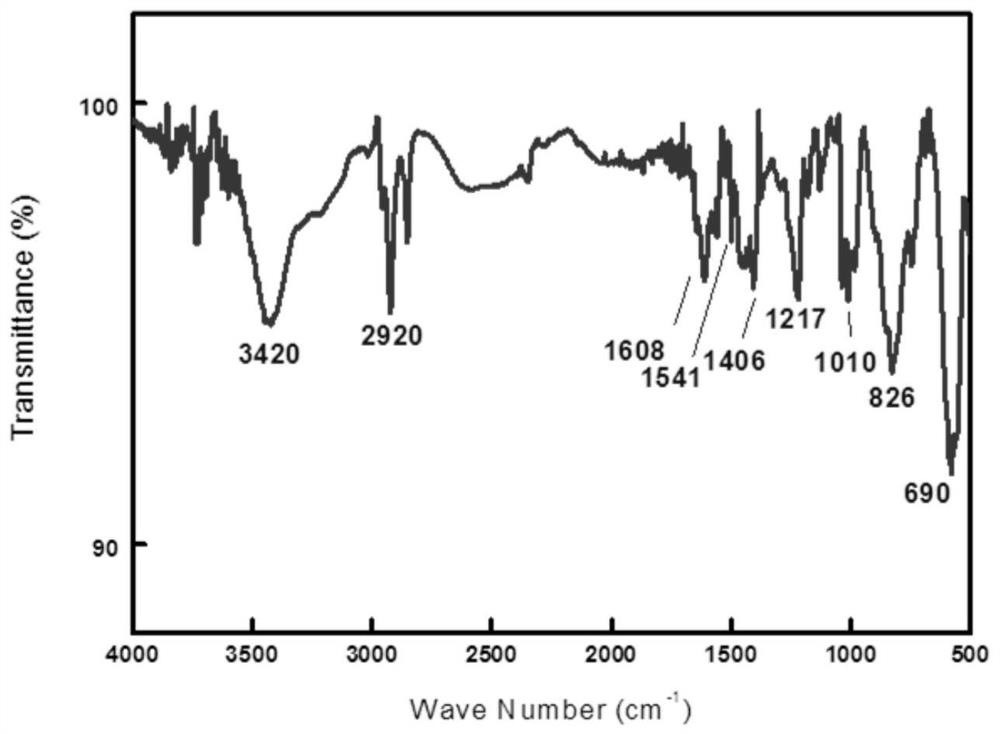

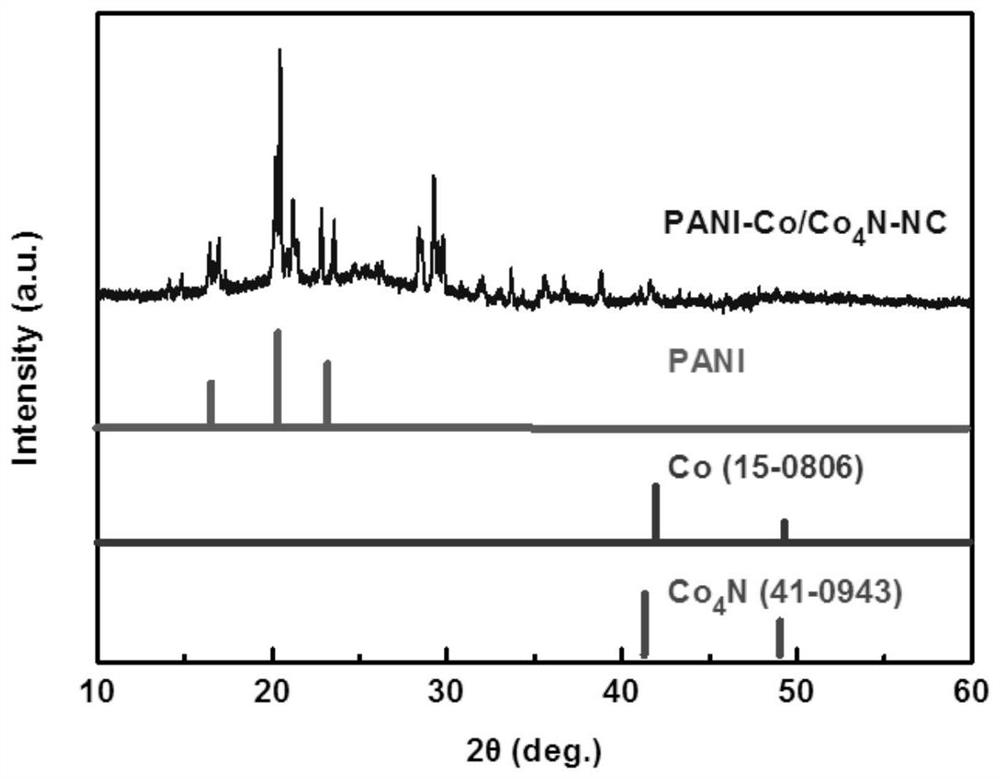

[0081] The prepared ZIF-67 precursor was placed in a porcelain boat, and heated in a tube furnace at 5 °C min -1 The speed is heated to 900°C, and deep heat treatment is carried out under N2 atmosphere for 2h; after the burnt material is slowly cooled to room temperature, the Co / Co 4 N-NC; will Co / Co 4 N-NC is ground into powder in a m...

Embodiment 2

[0094] A kind of polyaniline / MOF composite coating electrode material of the present invention, is synthesized by A component, B component, C component;

[0095] Specific steps are as follows:

[0096] 1) Synthesis of component B: Dissolve 1160mg Co(NO 3 ) 2 ·6H 2 0 and 20mg CTAB, and stirred rapidly; the above solution was quickly dissolved in a mixed solution composed of 18160mg 2-methylimidazole and 280mL deionized water, and vigorously stirred at room temperature for 6h; the precipitate was centrifuged and washed with ethanol 3 times to clarification; The material was placed in a vacuum oven for 12 hours to obtain a ZIF-67 precursor.

[0097] Place the prepared ZIF-67 precursor in a porcelain boat, heat it up to 900°C in a tube furnace at a rate of 5°C / min-1, and conduct a deep heat treatment for 2 hours in an N2 atmosphere; cool the fired material slowly After reaching room temperature, the Co / Co 4 N-NC; will Co / Co 4 N-NC is ground into powder in a mortar.

[0098]...

Embodiment 3

[0110] Embodiment three is the same as embodiment one, except that the composite coating electrode material is combined according to the ratio of mass ratio m (component A): m (component B): m (component C) = 1.5: 1: 800 become;

[0111] Step 3) When making the epoxy resin working electrode, the epoxy resin for potting is prepared at a mass ratio of epoxy resin:polyamide:solvent 2=7:3:0.5 and then centrifuged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com