Polymer-based antifouling coating based on thermal spraying technology as well as preparation method and application thereof

An anti-fouling coating and polymer technology, applied in anti-fouling/underwater coatings, coatings, devices for coating liquids on surfaces, etc. , to achieve the effect of remarkable antifouling effect, easy availability of raw materials and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In this embodiment, the substrate is selected from 316 stainless steel with a thickness of about 2mm, and the preparation method of the polymer-based antifouling coating based on thermal spraying technology is as follows:

[0049] (1) Clean the substrate with acetone, hydrochloric acid, and deionized water in sequence, and use 60-mesh brown corundum sand to roughen the surface of the substrate to increase the surface roughness of the substrate and improve the bonding strength of the coating. The air used for sandblasting The air pressure is 0.5MPa, and the blasting time is 60s;

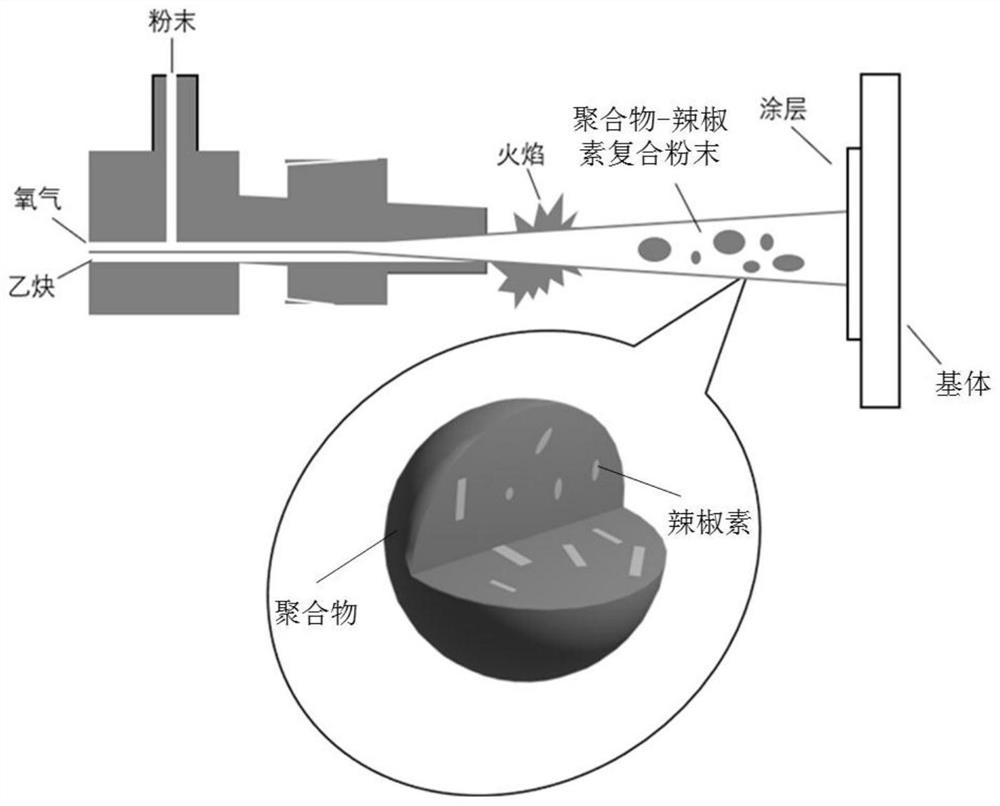

[0050] (2) Adopt the method for flame spraying to prepare polyethylene-capsaicin coating on the substrate surface after roughening treatment, use high-density polyethylene-capsaicin composite powder as spraying material, the massfraction of capsaicin in the composite powder is 2% , the process parameters of flame spraying are: combustion-supporting gas O 2 The pressure is 0.4MPa, the flow rate...

Embodiment 2

[0057] In this embodiment, the substrate is selected from 316 stainless steel with a thickness of about 2mm, and the preparation method of the polymer-based antifouling coating based on thermal spraying technology is as follows:

[0058] (1) Clean the substrate with acetone, hydrochloric acid, and deionized water in sequence, and use 120 mesh brown corundum sand to roughen the surface of the substrate to increase the surface roughness of the substrate and improve the bonding strength of the coating. The air pressure used for sandblasting 0.5MPa, sandblasting time is 60s;

[0059] (2) The flame spraying method is used to prepare polyethylene-capsaicin coating on the surface of the roughened substrate, and the high-density polyethylene-capsaicin composite powder is used as the spraying material, and the mass fraction of capsaicin in the composite powder is 1%. , the process parameters of flame spraying are: combustion-supporting gas O 2 The pressure is 0.6MPa, the flow rate is ...

Embodiment 3

[0065] In this embodiment, the substrate is selected from 316 stainless steel with a thickness of about 2mm, and the preparation method of the polymer-based antifouling coating based on thermal spraying technology is as follows:

[0066] (1) Clean the substrate with acetone, hydrochloric acid, and deionized water in sequence, and use 200 mesh brown corundum sand to roughen the surface of the substrate to increase the surface roughness of the substrate and improve the bonding strength of the coating. The air pressure used for sandblasting 0.5MPa, sandblasting time is 50s;

[0067] (2) The flame spraying method is used to prepare polyethylene-capsaicin coating on the surface of the roughened substrate, and the high-density polyethylene-capsaicin composite powder is used as the spraying material, and the mass fraction of capsaicin in the composite powder is 2.5%. , the process parameters of flame spraying are: combustion-supporting gas O 2 The pressure is 0.8MPa, the flow rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com