Organosilicon waterproof coating material

A waterproof coating and silicone technology, applied in the coating and other directions, can solve the problems of secondary pollution, low tensile strength and elongation at break, etc., and achieve the effects of low cost, improved waterproof effect, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

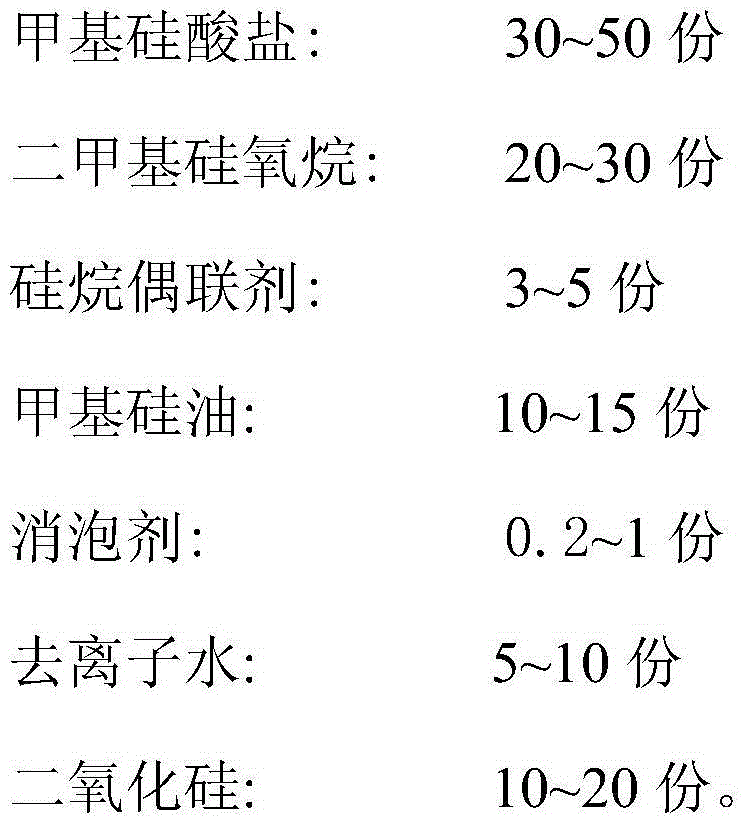

[0017] A kind of organosilicon waterproof coating of the present invention, is made up of the component of following parts by weight,

[0018]

[0019] The main component of the KH550 type silane coupling agent is 3-aminopropyltriethoxysilane.

[0020] The main component of the 602 defoamer is hexameric dioleate.

Embodiment 2

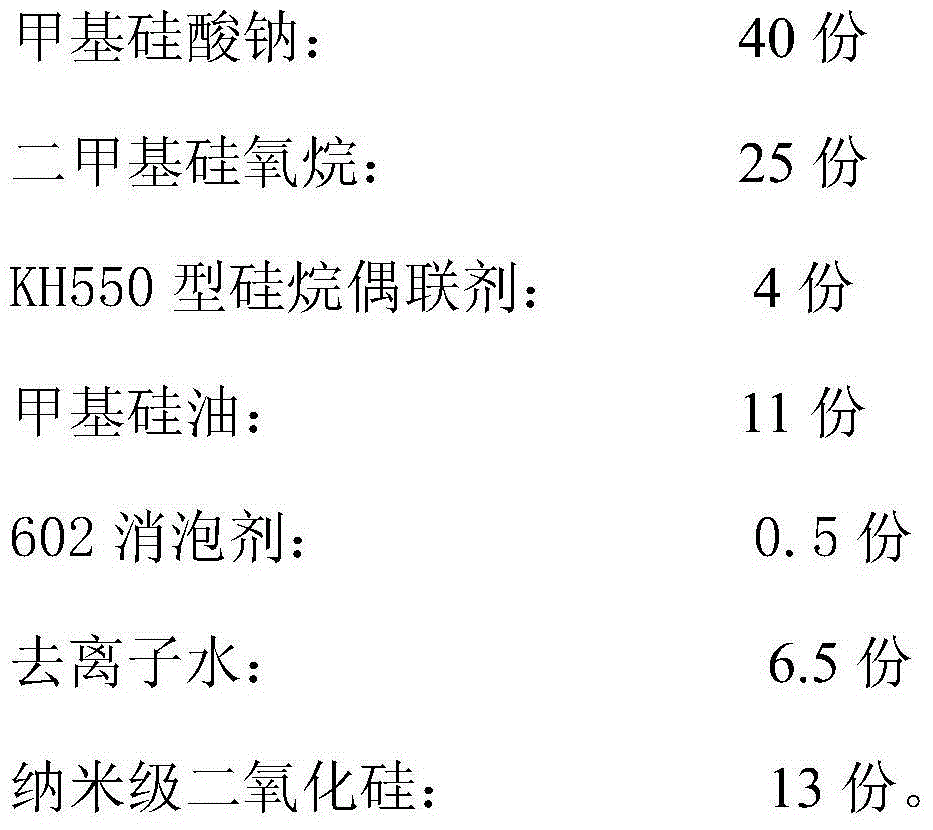

[0022] A kind of organosilicon waterproof coating of the present invention, is made up of the component of following parts by weight,

[0023]

[0024]

Embodiment 3

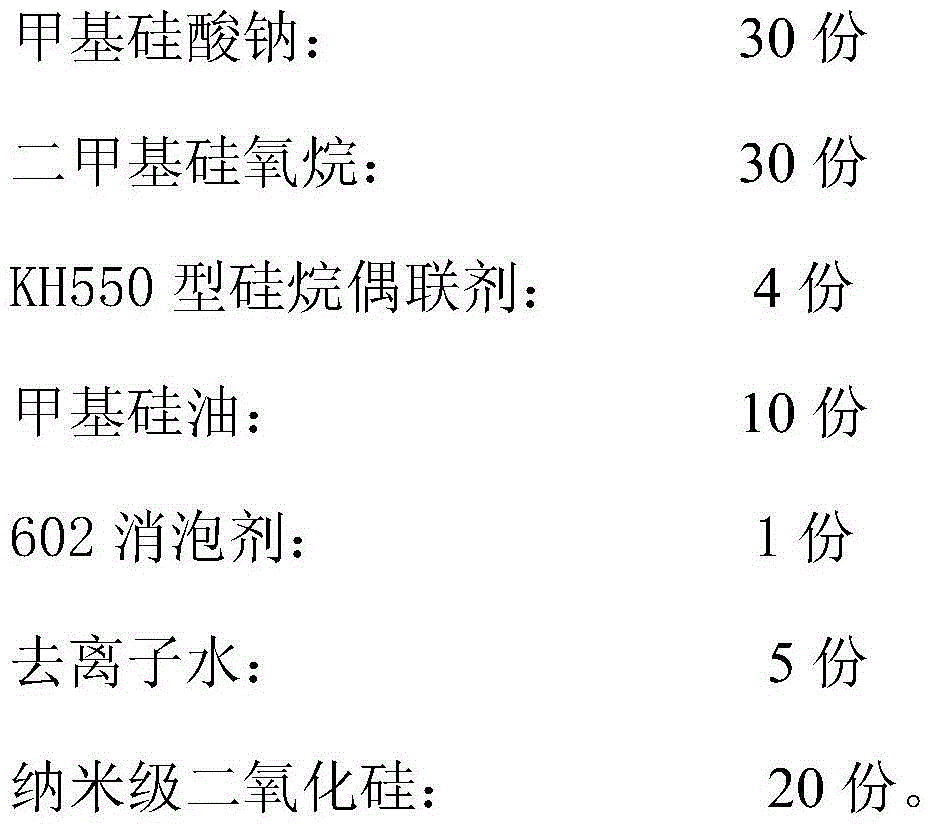

[0026] A kind of organosilicon waterproof coating of the present invention, is made up of the component of following parts by weight,

[0027]

[0028] Working process of the present invention:

[0029] During the working process of the organosilicon waterproof coating of the present invention, the coating can penetrate several millimeters into the wall and form a mesh waterproof film on the surface and inside of the wall to improve the waterproof effect. The waterproof film will not close the capillary pores of the base material, and the moisture can still Scatter from the inside of the wall to achieve waterproof and breathable effect; the paint is non-toxic, non-irritating, non-flammable, non-explosive, non-volatile, miscible with water, environmentally friendly and safe; good wear resistance, long service life; Chemical effect, no corrosion to steel bars, wide application range; easy to use, low cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com