Preparation method of carbon-based metal anticorrosive paint

A technology for anti-corrosion coatings and base metals, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of affecting the anti-corrosion performance of coatings, easy agglomeration and precipitation of carbon materials, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

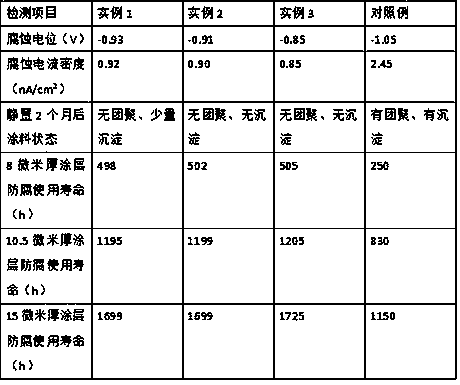

Examples

example 1

[0021] Weigh the pomelo peel and put it into a jet mill to pulverize for 1 hour to obtain the pulverized grapefruit peel, mix the pulverized grapefruit peel with biogas slurry and a zinc chloride solution with a mass fraction of 30% in a mass ratio of 10:15:7, and then flatten Spread the stainless steel trays on stainless steel trays, then move the stainless steel trays into a greenhouse with a temperature of 30°C and a relative air humidity of 60%, and let them stand for moldy treatment for 5 days to obtain moldy substances; move the moldy substances into a carbonization furnace under nitrogen protection. , heated up to 600°C, kept warm and carbonized for 1 hour to obtain porous biochar, mixed porous biochar with methylene chloride and triethylamine at a mass ratio of 5:25:1, and then stirred with a mixer at a speed of 800r / min. During the stirring process, octadecanoyl chloride with a mass of 20% of the porous biochar was added dropwise, and the stirring reaction was continue...

example 2

[0023] Weigh the pomelo peel and put it into a jet mill to pulverize for 2 hours to obtain the pulverized grapefruit peel, mix the pulverized grapefruit peel with biogas slurry and a zinc chloride solution with a mass fraction of 30% in a mass ratio of 10:15:7, and then flatten Lay it on a stainless steel tray, then move the stainless steel tray into a greenhouse with a temperature of 33°C and a relative air humidity of 65%, and let it stand for moldy treatment for 6 days to obtain moldy matter; move the moldy matter into a carbonization furnace, under nitrogen protection , heated to 650°C, kept warm and carbonized for 2 hours to obtain porous biochar, mixed porous biochar with dichloromethane and triethylamine according to the mass ratio of 5:25:1, and then stirred with a mixer at a speed of 850r / min, During the stirring process, octadecanoyl chloride with a mass of 20% porous biochar was added dropwise, and the stirring reaction was continued for 4 hours. After the reaction w...

example 3

[0025] Weigh the pomelo peel and put it into a jet mill to pulverize for 2 hours to obtain the pulverized grapefruit peel, mix the pulverized grapefruit peel with biogas slurry and a zinc chloride solution with a mass fraction of 30% in a mass ratio of 10:15:7, and then flatten Spread it on a stainless steel tray, and then move the stainless steel tray into a greenhouse with a temperature of 35°C and a relative air humidity of 70%, and let it stand for 7 days for moldy treatment to obtain moldy matter; move the moldy matter into a carbonization furnace, under nitrogen protection. , heated to 700°C, kept warm and carbonized for 2 hours to obtain porous biochar, mixed porous biochar with methylene chloride and triethylamine according to the mass ratio of 5:25:1, and then stirred with a stirrer at a speed of 900r / min. During the stirring process, octadecanoyl chloride with 20% of the mass of porous biochar was added dropwise, and the stirring reaction was continued for 4 hours. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com