Soil heavy metal restoration agent and preparation method thereof

A technology of heavy metals and restorative agents, applied in the field of soil remediation, can solve the problems that the treatment effect cannot be achieved, and the application effect of a single magnetic material is easily affected by soil conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

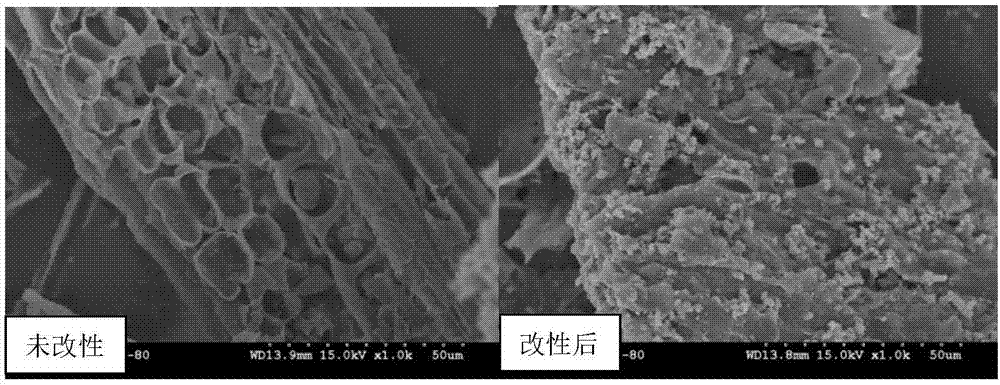

[0038] (1) Mix the ground and sieved rice straw with a particle size of 0.25-1 mm and ferric nitrate solution with a concentration of 0.2 mol / L at a ratio of 3:5 (W / V), stir at room temperature for 24 hours, and then continue to soak Add 20% of the mass of rice stalks into the solution, and at the same time, add manganese chloride at a ratio of 1:25 to the mass of the rice stalks, stir intermittently at room temperature, leave it for 24 hours, and drain the soaked rice stalks , dried at 80°C, heated to 550°C at a rate of 25°C per minute under nitrogen-protected anaerobic conditions, and kept for 3 hours, and then continued to cool to room temperature under the condition of isolated air, that is, the iron-manganese-rich oxide Rice straw charcoal with material and calcium.

[0039] (2) Ferric sulfate heptahydrate and water are made into a solution at a ratio of 1:70, and slowly add 1M potassium hydroxide to adjust the pH of the solution to 12. After filtering, dilute the filtrat...

Embodiment 2

[0041] Grind and sieve corn stalks with a particle size of 0.25-1 mm and ferric chloride solution with a concentration of 0.2 mol / L at a ratio of 1:2 (W / V), stir at room temperature for 24 hours, and then continue to add to the soaking solution Add quicklime of 22% of the mass of the rice straw, and at the same time, add manganese sulfate in a ratio of 1:20 to the mass of the rice straw, stir intermittently at room temperature, place it for 24 hours, drain the soaked rice straw, and heat at 80°C Under the condition of anaerobic under the protection of nitrogen, the temperature was raised to 600°C at a rate of 30°C per minute, and kept for 2 hours, and then continued to cool to room temperature under the condition of isolated air, that is, rich in iron manganese oxides and calcium. Elemental Rice Straw Charcoal.

[0042] Make a solution of ferric sulfate heptahydrate and water at a ratio of 1:80, and slowly add 1M KOH to make the pH of the solution 12. After filtering, dilute t...

Embodiment 3

[0044] Mix the ground and sieved wood chips with a particle size of 0.25-1 mm and the ferric nitrate solution with a concentration of 0.2 mol / L at a ratio of 7:10 (W / V), stir at room temperature for 24 hours, and then continue to add rice to the soaking solution 25% quicklime of the straw mass, and at the same time, add potassium permanganate at a ratio of 1:26 to the mass ratio of the rice straw, stir intermittently at room temperature, place it for 24 hours, drain the soaked rice straw, and heat it at 80°C Under the condition of anaerobic under the protection of nitrogen, the temperature was raised to 600°C at a rate of 30°C per minute, and kept for 2 hours, and then continued to cool to room temperature under the condition of isolated air, that is, rich in iron manganese oxides and calcium. Elemental Rice Straw Charcoal.

[0045] Make a solution of ferric sulfate heptahydrate and water at a ratio of 1:60, and slowly add 1M KOH solution to adjust the pH of the solution to 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com