Modified environment-friendly waterborne anticorrosion coating and preparation method thereof

An anti-corrosion coating and environmental-friendly technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of increased coating manufacturing costs, large amount of environmentally friendly anti-rust pigments, and lack of long-term anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

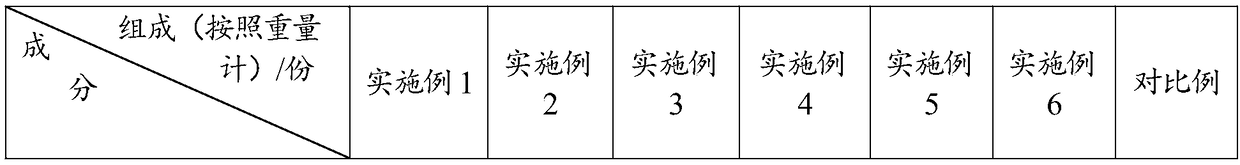

Embodiment 1

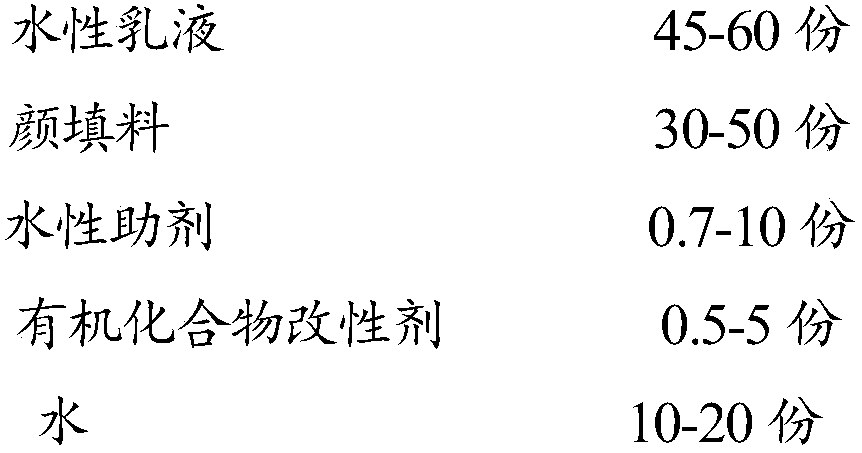

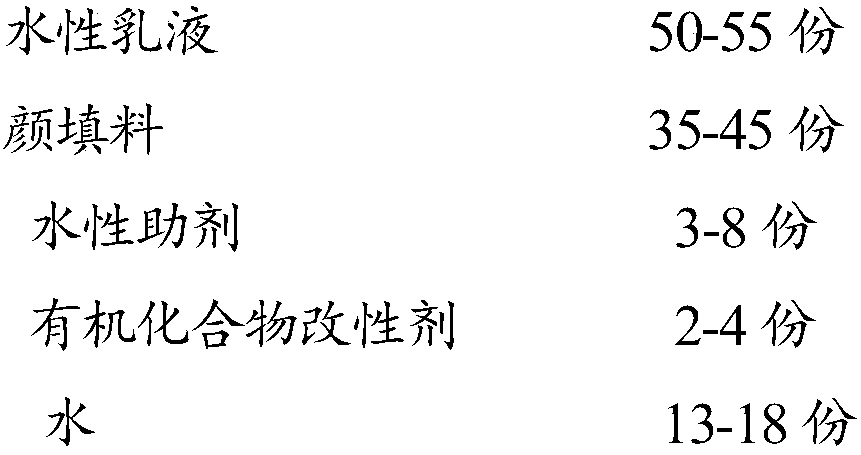

[0033] A modified environment-friendly water-based anti-corrosion coating comprises the following components: water-based emulsion, pigments and fillers, water-based additives, organic compound modifiers and water. Wherein the aqueous emulsion is a styrene-acrylic emulsion, the hydrated particle size of the aqueous emulsion is 300nm, the solid content is 40wt%, the minimum film-forming temperature is 30°C, and the glass transition temperature is 25°C. The organic compound modifier is 142DA from Ascodi, France. The amino group and phosphonic acid group in the organic compound modifier are strong polar groups, which are easy to complex with other components such as substrates, pigments and fillers, and film-forming substances to form chemical bonds, thereby firmly adsorbing on substrates, pigments, etc. The surface of other components such as fillers and film-forming substances improves the adhesion of the coating film; compared with inorganic anti-rust pigments, because the org...

Embodiment 2

[0044] The difference between the modified environment-friendly water-based anticorrosion coating in Example 2 and Example 1 is that the organic compound modifier is 143 from Ascodi, France.

[0045] The pigments and fillers include common commercial 2500 mesh iron yellow.

[0046] The wetting and dispersing agent is Tego 750W from Germany.

[0047] The defoamer is BYK022 from German BYK Chemicals.

[0048] The pH regulator is triethanolamine.

[0049] The co-solvent is the PM of Dow Huaxue.

[0050] The difference between the preparation method of the modified environment-friendly water-based anti-corrosion paint of Example 2 and Example 1 is that the stirring speed in the step (1) is 700r / min, and the stirring time is 8min.

[0051] The grinding time in the step (2) is 26min.

[0052] In the step (3), the stirring speed is 1100r / min, and the stirring time is 13min.

[0053] In the step (4), the stirring speed is 600r / min, and the stirring time is 8min.

[0054] In the ...

Embodiment 3

[0056] The difference between the modified environment-friendly water-based anticorrosion coating in Example 3 and Example 1 is that the organic compound modifier is 144DA from Ascodi, France.

[0057] The pigments and fillers include common commercial 2500 mesh iron black.

[0058] The wetting and dispersing agent is Tego 755W from Germany.

[0059] The defoaming agent is BYK024 from German BYK Chemicals.

[0060] The pH regulator is diethanolamine.

[0061] The co-solvent is DPNP of Dow Huaxue.

[0062] The difference between the preparation method of the modified environment-friendly water-based anti-corrosion paint of embodiment 3 and embodiment 1 is that: in the step (1), the stirring speed is 900r / min, and the stirring time is 12min.

[0063] The grinding time in the step (2) is 37min.

[0064] In the step (3), the stirring speed is 1200r / min, and the stirring time is 15min.

[0065] In the step (4), the stirring speed is 650r / min, and the stirring time is 10min.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com