Corrosion-resistant water-based foliar texture effect paint as well as preparation and construction methods thereof

A texture and water-based technology, applied in the field of anti-corrosion water-based foliage texture effect paint and its preparation, can solve the problems of solvent-based coatings polluting the environment, hidden safety hazards, and endangering human health, and achieve excellent anti-corrosion function, clear lines, and excellent anti-corrosion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

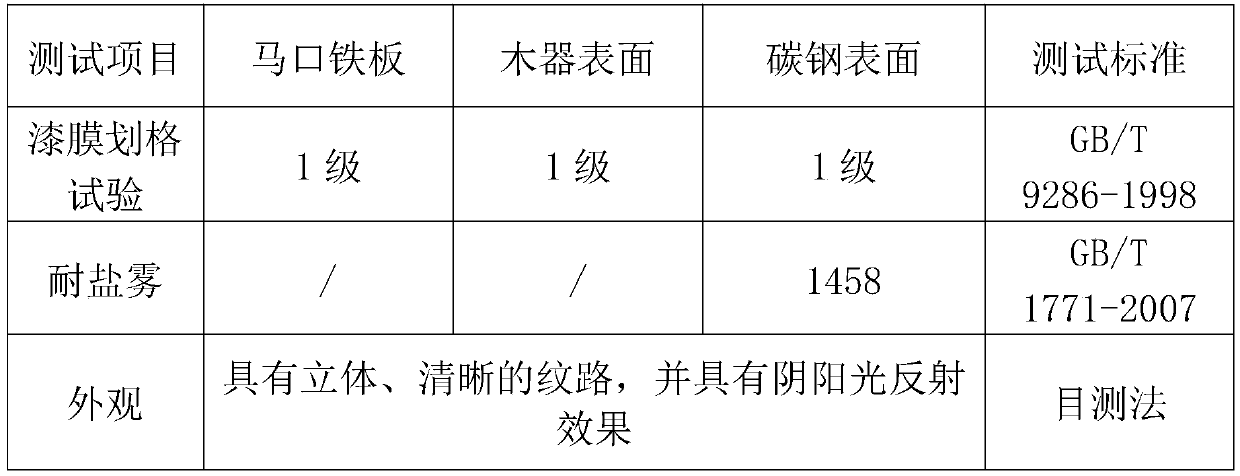

Embodiment 1

[0026] A kind of anti-corrosion water-based foliage texture effect paint, which is composed of A component and B component, wherein A component includes the following ingredients in mass percentage: 40% of water-based epoxy resin, 3% of propylene glycol monomethyl ether, 1,6- Hexylene glycol diglycidyl ether 5%, mineral oil defoamer 2%, oily bentonite 1% (BYK Garamite-7305), phosphate dispersant 2%, cement 45%, titanium dioxide 1%, quartz sand 1 %; B component includes the following mass percentage ingredients: water-based epoxy curing agent 50%, water 38%, water-based bentonite 1% (BENTONE EW), polyether siloxane polymer 0.1%, water-based wetting agent 0.2% ( TEGO-4100), propylene glycol monomethyl ether 2%, zinc phosphate 0.2%, water-based color paste 8.5%.

[0027] The preparation method of the A component: Weigh the raw materials in the A component according to the above formula, add 1,6-hexanediol diglycidyl ether and oily bentonite to the water-based epoxy resin and disp...

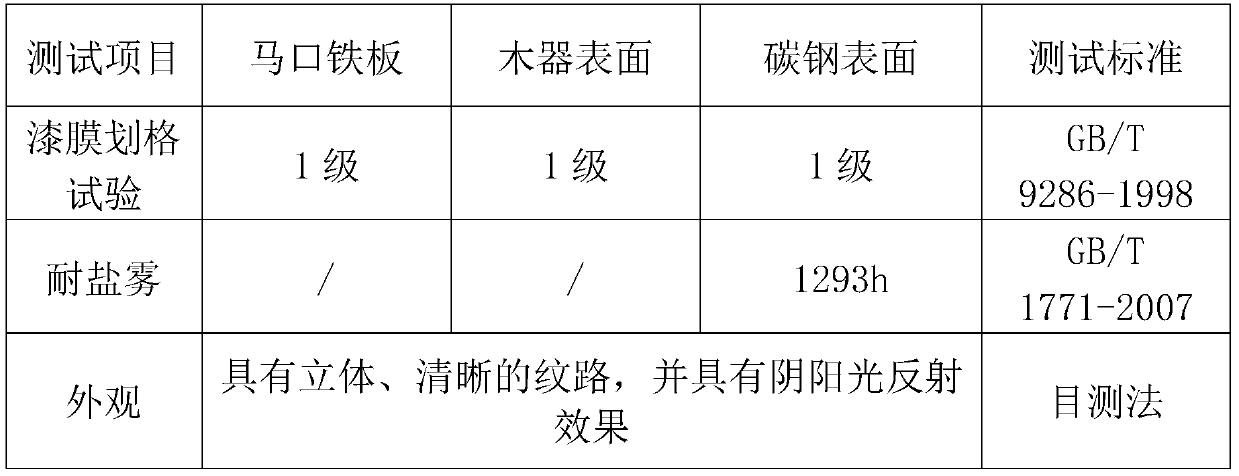

Embodiment 2

[0034] A kind of anti-corrosion water-based foliage texture effect paint, which is composed of A component and B component, wherein the A component includes the following components in mass percentage: 45% of water-based epoxy resin, 1.5% of propylene glycol methyl ether acetate, polypropylene glycol two Glycidyl ether 2%, mineral oil defoamer 1%, oily bentonite 0.1% (BYK Garamite-7305), polyacid homopolymer dispersant 0.4%, cement 40%, azo pigment 4%, precipitated barium sulfate 6 %; B component includes the following mass percentages: water-based epoxy curing agent 55.9%, water 35%, water-based bentonite 0.1%

[0035] (BENTONE EW), polyether siloxane polymer 1%, water-based wetting agent 1% (TEGO-4100), propylene glycol methyl ether acetate 4%, aluminum tripolyphosphate 2.5%, water-based color paste 0.5%.

[0036] The preparation method of the A component: Weigh the raw materials in the A component according to the above formula, add polypropylene glycol diglycidyl ether and...

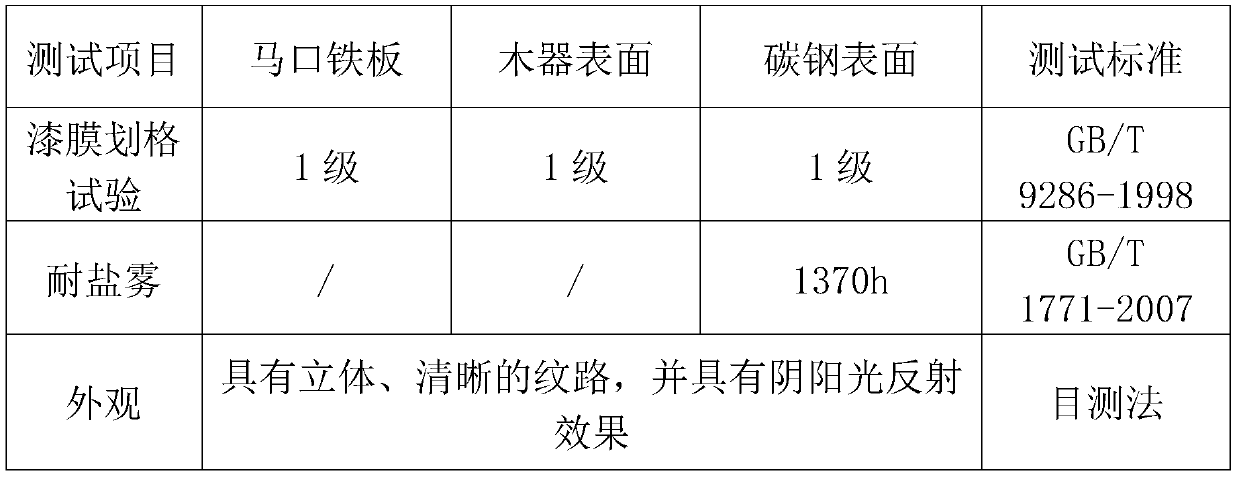

Embodiment 3

[0043] An anti-corrosion water-based foliage texture effect paint, which is composed of A component and B component, wherein A component includes the following components in mass percentage: 50% of water-based epoxy resin, 0.1% of propylene glycol monomethyl ether, o-cresyl shrink Glycerin ether 0.2%, mineral oil defoamer 0.2%, oily bentonite 0.5% (BYK Garamite-7305), polyacid copolymer dispersant 1%, cement 30%, quinacridone pigment 5%, phthalocyanine pigment 3 %, talcum powder 10%; component B includes the following ingredients in mass percentage: water-based epoxy curing agent 58%, water 30%, water-based bentonite 0.5% (BENTONE EW), polyether siloxane polymer 0.5%, water-based emulsifier Wet agent 0.5% (TEGO-4100), propylene glycol monomethyl ether 3%, zinc powder 4.5%, water-based color paste 3%.

[0044] The preparation method of the A component: Weigh the raw materials in the A component according to the above formula, add o-cresyl glycidyl ether and oily bentonite to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com