Surface treatment method and device for nickel-chromium alloy wire

A surface treatment device, a technology of nickel-chromium alloy, which is applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of inability to stabilize the rust layer, high toxicity of the treatment solution, and high environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

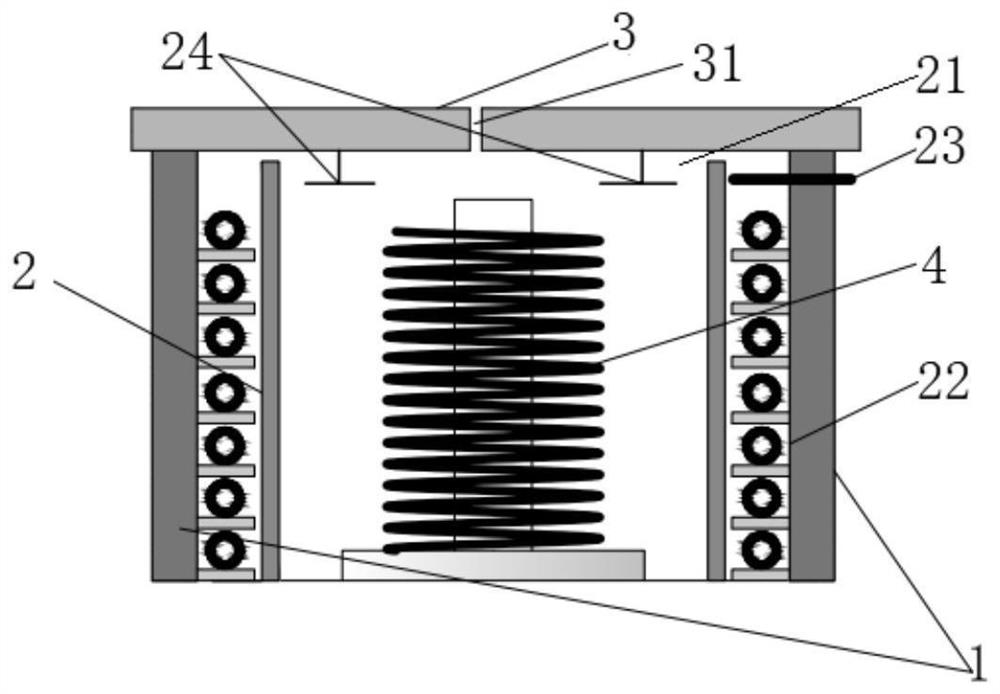

[0060] 1. A surface treatment device for nickel-chromium alloy wire, comprising a furnace body, a furnace furnace and a furnace cover,

[0061] The furnace is arranged inside the furnace body, the furnace is provided with an opening, the wall of the furnace is provided with an electric furnace wire, and the hollow part of the furnace is provided with a place for placing a nickel-chromium alloy wire. A heat treatment chamber, the heat treatment chamber is provided with an air agitator;

[0062] The furnace cover is arranged on the opening, the furnace cover is detachably connected to the furnace, and the furnace cover is provided with a vent.

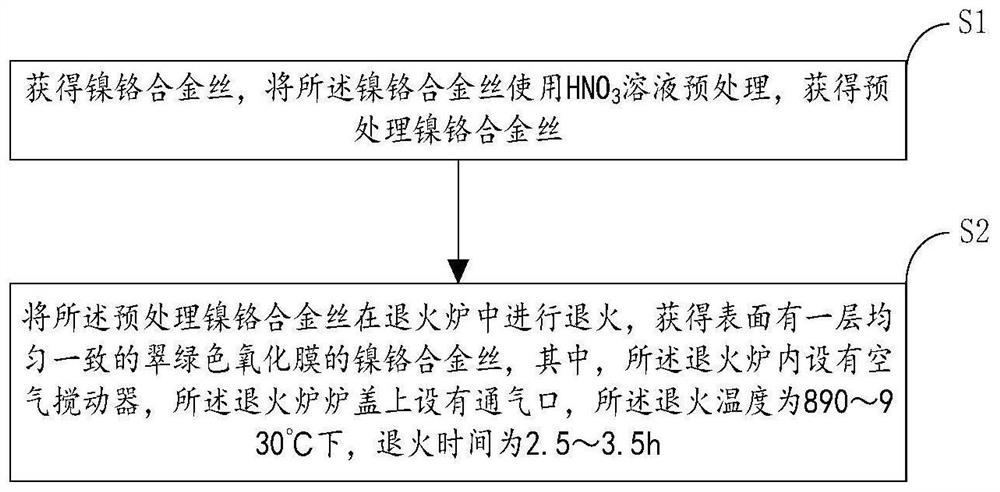

[0063] 2. A surface treatment method for nickel-chromium alloy wire, said method comprising:

[0064] A nickel-chromium alloy wire is obtained, and the chemical composition of the nickel-chromium alloy wire includes: C: 0.01%-0.02%; Si: 0.9%-1.5%; Mn: 0.15%-0.2%; Cr: 20.5%- 22%; P<0.015%; S<0.0015%; Al: 0.2%~0.6%; Fe: 0.2%~1.5%; Re: 0....

Embodiment 2

[0068] HNO described in this example 3 The concentration of the solution is 150g / l, the flow rate of the air agitator is 80m 3 / min, the annealing temperature is 890°C, and the annealing time is 3.5h.

Embodiment 3

[0070] HNO described in this example 3 The concentration of the solution is 90g / l, the flow rate of the air agitator is 90m 3 / min, the annealing temperature is 930°C, and the annealing time is 2.5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com