A kind of high-strength corrosion-resistant steel bar and its manufacturing method

A manufacturing method and corrosion-resistant technology, which is applied in the field of construction steel, can solve the problems of protective layer cracking, peeling, and reducing the mechanical properties of steel bars, and achieve the effect of high-strength corrosion resistance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

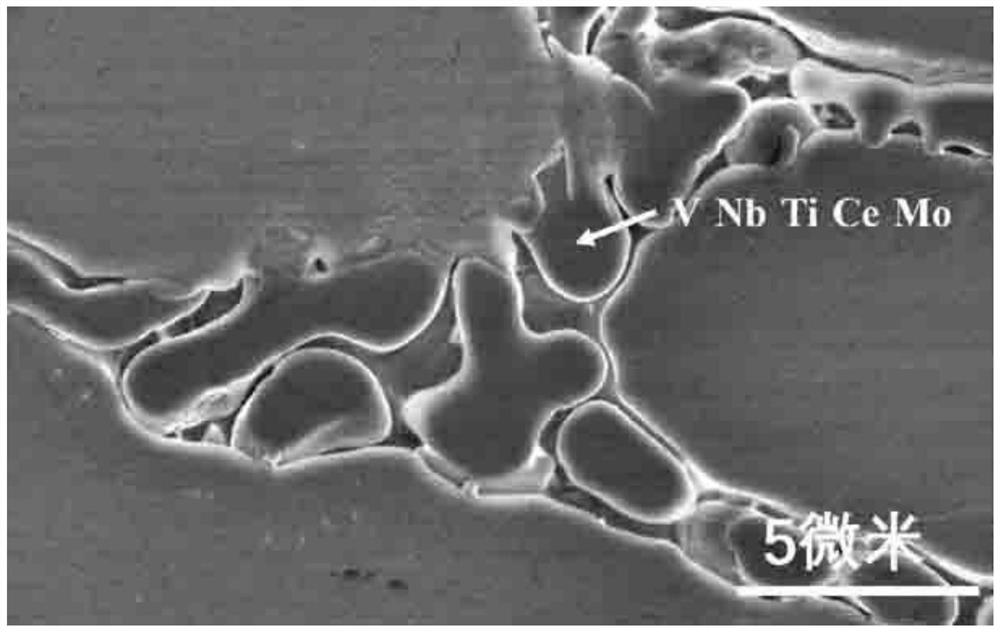

Image

Examples

Embodiment 1

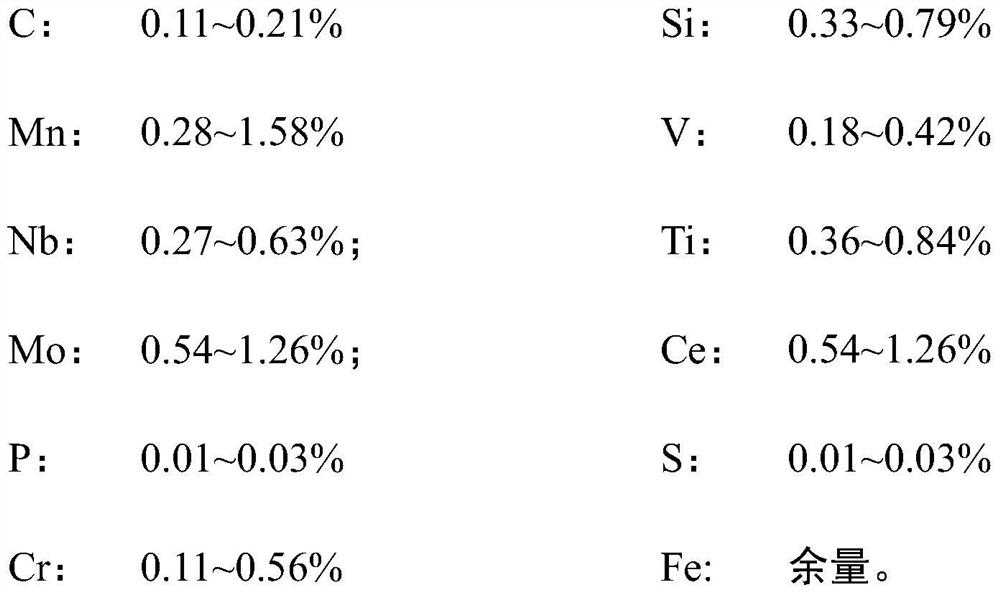

[0031] A high-strength corrosion-resistant steel bar, comprising the following components in mass percentage (wt.%):

[0032]

[0033] In this embodiment, the mass ratio of V, Nb, Ti, Ce and Mo is: V:Nb:Ti:Ce:Mo=1:2:2:3:4.

[0034] A method for preparing high-strength corrosion-resistant steel bars, the specific steps are as follows:

[0035] S1: Smelting: heating scrap steel and molten iron to 1640°C in an electric furnace to completely melt them to obtain molten steel;

[0036] S2: Refining: transfer the molten steel obtained in S1 to the refining furnace, and after heating up to 1650°C, add C, Si, V, Nb, Ti, Ce, Mo, Mn and Cr elements according to the mass ratio into the refining furnace Refining in medium to obtain refined molten steel;

[0037] S3: Continuous casting: control the casting temperature to 1520°C, casting speed to 3.5m / min, and continuously cast to obtain steel slabs;

[0038] S4: Heating: Heating by a walking heating furnace. The furnace is divided int...

Embodiment 2

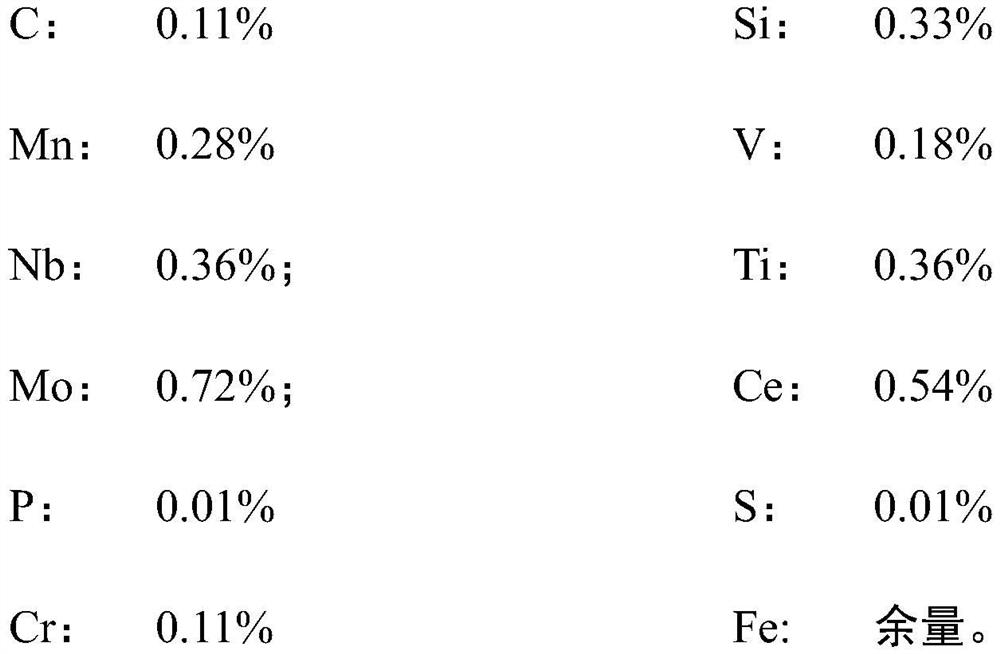

[0042] A high-strength corrosion-resistant steel bar, comprising the following components in mass percentage (wt.%):

[0043]

[0044]

[0045] In this embodiment, the mass ratio of V, Nb, Ti, Ce and Mo is: V:Nb:Ti:Ce:Mo=1:0.8:2:3.7:1.59.

[0046] A method for preparing high-strength corrosion-resistant steel bars, the specific steps are as follows:

[0047] S1: Smelting: heating scrap steel and molten iron to 1660°C in an electric furnace to completely melt them to obtain molten steel;

[0048] S2: Refining: transfer the molten steel obtained in S1 to the refining furnace, and after heating up to 1700°C, add C, Si, V, Nb, Ti, Ce, Mo, Mn and Cr elements prepared according to the mass ratio into the refining furnace Refining in medium to obtain refined molten steel;

[0049] S3: Continuous casting: control the casting temperature to 1530°C, casting speed to 2.9m / min, and continuously cast to obtain steel billets;

[0050]S4: Heating: Heating by a walking heating furnac...

Embodiment 3

[0054] A high-strength corrosion-resistant steel bar, comprising the following components in mass percentage (wt.%):

[0055]

[0056] In this embodiment, the mass ratio of V, Nb, Ti, Ce and Mo is: V:Nb:Ti:Ce:Mo=1:1.5:2:2.43:3.

[0057] A method for preparing high-strength corrosion-resistant steel bars, the specific steps are as follows:

[0058] S1: Smelting: heating scrap steel and molten iron to 1680°C in an electric furnace to completely melt them to obtain molten steel;

[0059] S2: Refining: transfer the molten steel obtained in S1 to the refining furnace, and after heating up to 1750°C, add C, Si, V, Nb, Ti, Ce, Mo, Mn and Cr elements prepared according to the mass ratio into the refining furnace Refining in medium to obtain refined molten steel;

[0060] S3: Continuous casting: control the casting temperature to 1540°C, casting speed to 2.2m / min, and continuously cast to obtain steel slabs;

[0061] S4: Heating: Heating by a walking heating furnace. The furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com