AlSb/CIS thin film solar cell of mechanical laminated layer

A thin-film solar cell and lamination technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficult control of chemical ratio, reduced efficiency, and high work function of CdTe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

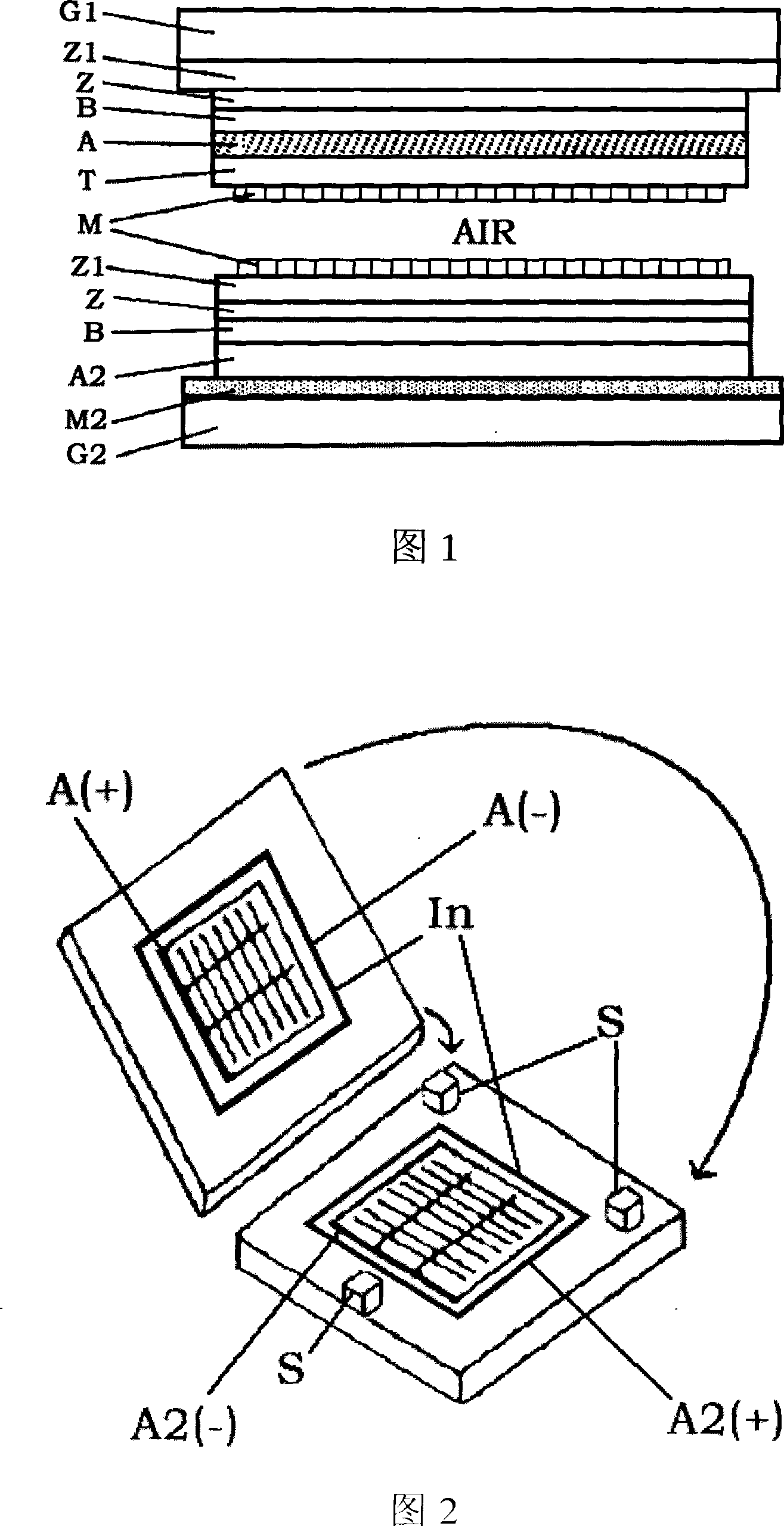

[0018] 1 Preparation of CIS (A2) bottom cell

[0019] 1.1 On Soda lime glass (G2), use a molybdenum target with a purity of 99.999%, in a background vacuum of ~10-4 Pa, the working gas is argon, the sputtering pressure is ~1Pa, and the sputtering power is 20~300W. Molybdenum (M2) with a thickness of about 0.9-1.5 μm;

[0020] 1.2 Take out the sample Soda lime glass (G2) / molybdenum (M2) after sputtering, in a vacuum of ~10 -4 Pa, adopt copper, indium, selenium three sources (purity is 99.99%) co-evaporation method to prepare CIS (A2), when sample temperature is 300 ℃, adjust the speed ratio (0.3~0.7) of copper, indium, selenium: (0.8 ~1.2):(2.2~2.6), deposit copper-rich CIS with a thickness of 0.5~1.5μm, then adjust the sample temperature to 450°C, and adjust the speed ratio to (0.1~0.5):(0.8~1.2):(1.8~2.2) , and then deposited a poor copper CIS 1.5 ~ 2.5μm;

[0021] 1.3 After the sample Soda lime glass (G2) / molybdenum (M2) / CIS (A2) is cooled, it is taken out, and the buffer...

Embodiment 2

[0034] The preparation method of ~50nm buffer layer cadmium sulfide (B) in step 1.3 and step 2.2 in embodiment 1 is changed to radio frequency sputtering method to obtain nanostructured buffer layer cadmium sulfide (B). Among them, the purity of CdS target is 99.99%, and the background vacuum is ~10 -4 Pa, the working gas is argon oxygen (oxygen 1% ~ 2%), the working pressure is 1 ~ 2Pa, the sputtering power is 30 ~ 100W, under the above conditions, the buffer layer cadmium sulfide (B ). Other processes are unchanged, the same as in Embodiment 1. Similarly, a double-junction four-terminal AlSb / CIS mechanical stack battery with a buffer layer of cadmium sulfide (B) in nanostructures can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com