Back contact heterojunction solar battery based on P-type silicon slice

A solar cell and heterojunction technology, applied in the field of solar cells, can solve problems such as increasing the density of carrier recombination defects, affecting the collection and transmission of photogenerated current, and affecting the conversion efficiency of solar cells, so as to simplify the appearance requirements of the welding process and save energy. Production time, the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

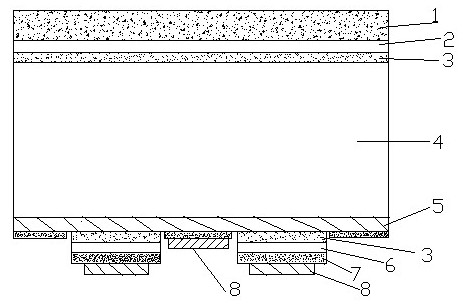

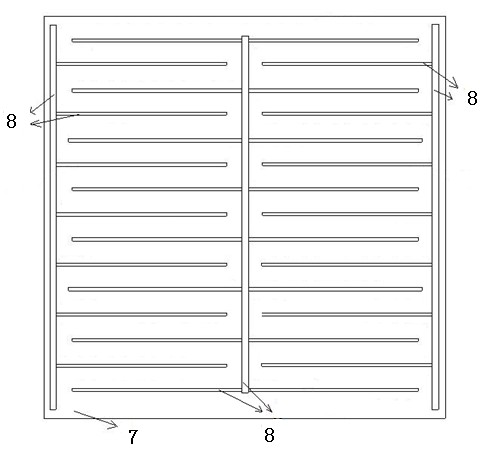

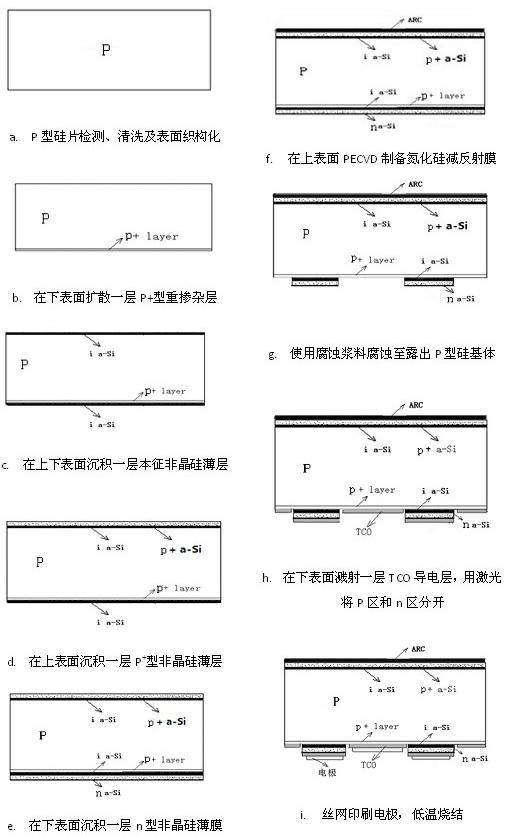

[0029]The P-type crystalline silicon 4 is selected from a P-type single crystal silicon wafer, and the surface of the P-type crystalline silicon 4 is pre-cleaned and surface textured by using a semiconductor cleaning process. The thickness of the P-type crystalline silicon 4 used is 200um, the resistivity is 0.5~3Ω.cm, the silicon dioxide layer on the surface of the silicon wafer is removed with 1~5% hydrofluoric acid, and the concentration is less than 3% NaOH and IPA (isopropyl Alcohol) in the mixed solution at about 80°C to prepare pyramid-shaped suede. Increase the absorption of sunlight, increase the area of the PN junction, and increase the short-circuit current. The subsequent P-type crystalline silicon 4 is cleaned by an acid cleaning process and dried. Put the P-type crystalline silicon 4 after texturing into a diffusion furnace and use borane to perform single-sided re-diffusion at about 850°C, forming a layer of P on the lower surface of the P-type crystalline si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com