Back contact heterojunction solar battery based on P-type silicon slice

A solar cell and heterojunction technology, applied in the field of solar cells, can solve problems such as increasing the density of carrier recombination defects, affecting the collection and transmission of photogenerated current, and affecting the conversion efficiency of solar cells, so as to simplify the appearance requirements of the welding process and save energy. Production time, the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

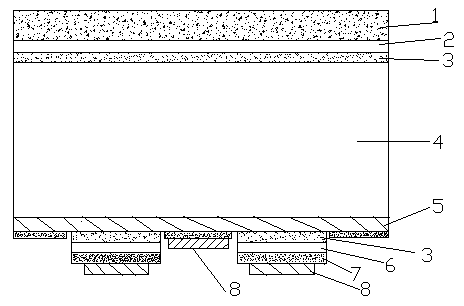

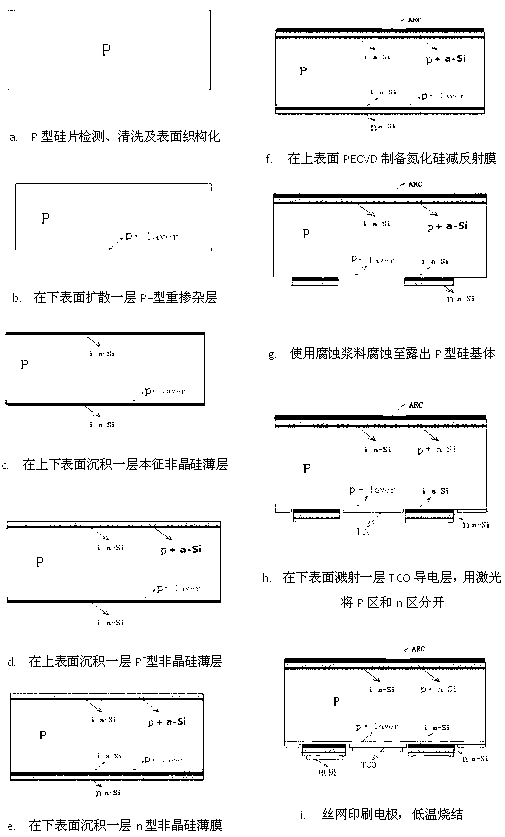

[0030] Using the plasma enhanced chemical vapor deposition (PECVD) process, a layer of intrinsic amorphous silicon film 3 is deposited on the upper and lower surfaces of the crystalline silicon after diffusion at 250°C, with a thickness of about 5nm, which has a passivation effect. Deposit a high-concentration P+ a-Si amorphous silicon film 2 on the upper surface of crystalline silicon with a thickness of 5-10nm; deposit a thin layer of N-a-si amorphous silicon 6 on the back surface with a thickness of 5-10nm; at 400°C Next, use PECVD to grow silicon nitride light-receiving surface anti-reflection film 1 on the front surface of the silicon wafer, with a thickness of 85nm and a refractive index of 2.05; its function reduces the reflection loss on the surface of the battery, and the light reflection loss of the solar battery after coating can be reduced to 4 % within; at the same time, effectively passivate the surface and volume of the battery, reduce the recombination center, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com