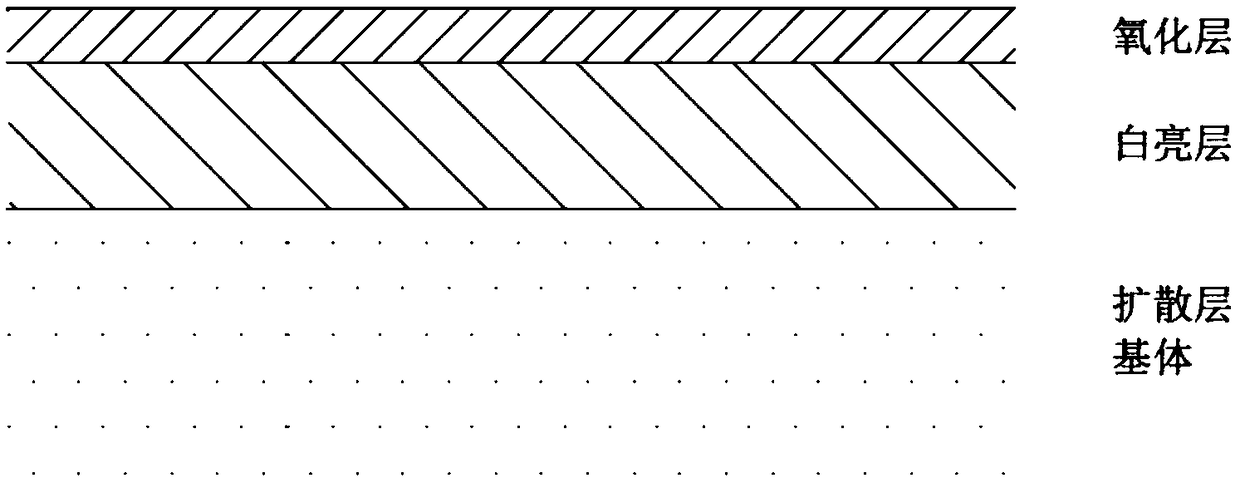

Gas nitrocarburizing and post-oxidation compounded treatment process

A technology of compound treatment and gas nitrogen, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of no related reports on oxidation compound treatment technology, reduction of fatigue resistance of materials, reduction of production efficiency, etc. , to achieve the effect of reducing friction coefficient, improving corrosion resistance and wear resistance, and easy operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0044] The steel is treated by gas nitrocarburizing and post-oxidation composite treatment process, the specific process is as follows: polishing → furnace loading → pre-cleaning → pre-oxidation (temperature is 420 ° C) → gas nitrocarburizing (NH 3 +N 2 +CO 2 , temperature 600→560°C, time 4h, oil cooling)→polishing→post-oxidation (water vapor, temperature 500°C, time 2h)→rust prevention; the differences in process parameters of Examples 1-5 are as shown in Table 1, and The materials treated in Examples 1-5 were tested for white bright layer, oxide layer thickness, surface hardness and 120h salt spray test, and the results are shown in Table 1.

[0045] Table 1

[0046]

[0047] In summary, compared with QPQ salt bath composite treatment, gas nitrocarburizing + post-oxidation composite treatment uses nitrogen, ammonia, carbon dioxide, and water vapor as raw materials, has no pollution problem, is easy to operate, and greatly reduces production costs. White bright layer an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com