Decompression diffusion technology for manufacturing high-square-resistance battery pieces

A diffusion process and cell technology, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems that are difficult to meet the high efficiency and low cost development of solar cells, the difficulty of preparing shallow surface PN junctions, and the absorption rate of diffuse phosphorus sources Low-level problems, to achieve the effect of increasing production capacity, reducing consumption, and avoiding turbulent flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

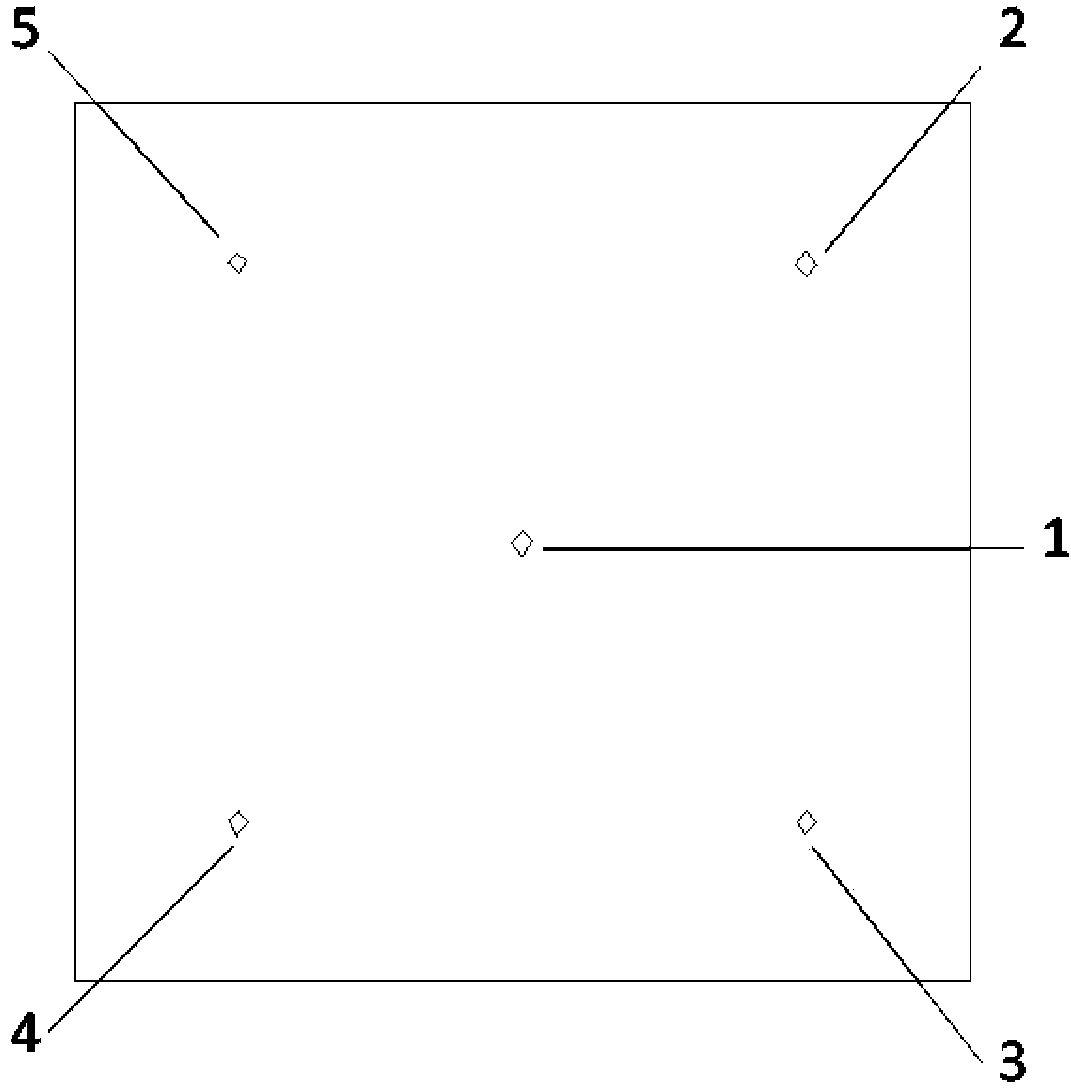

Image

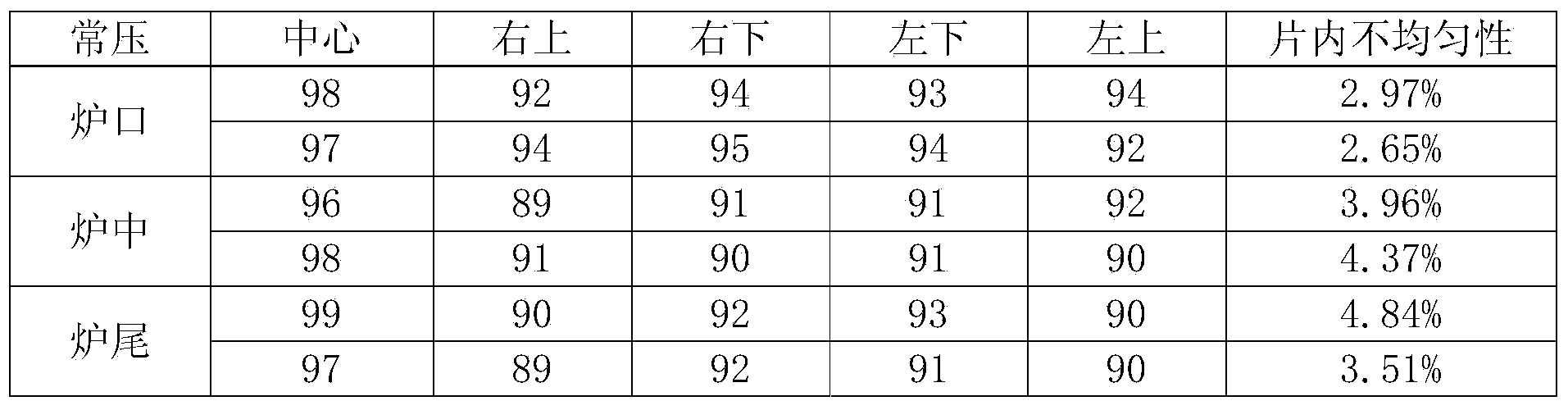

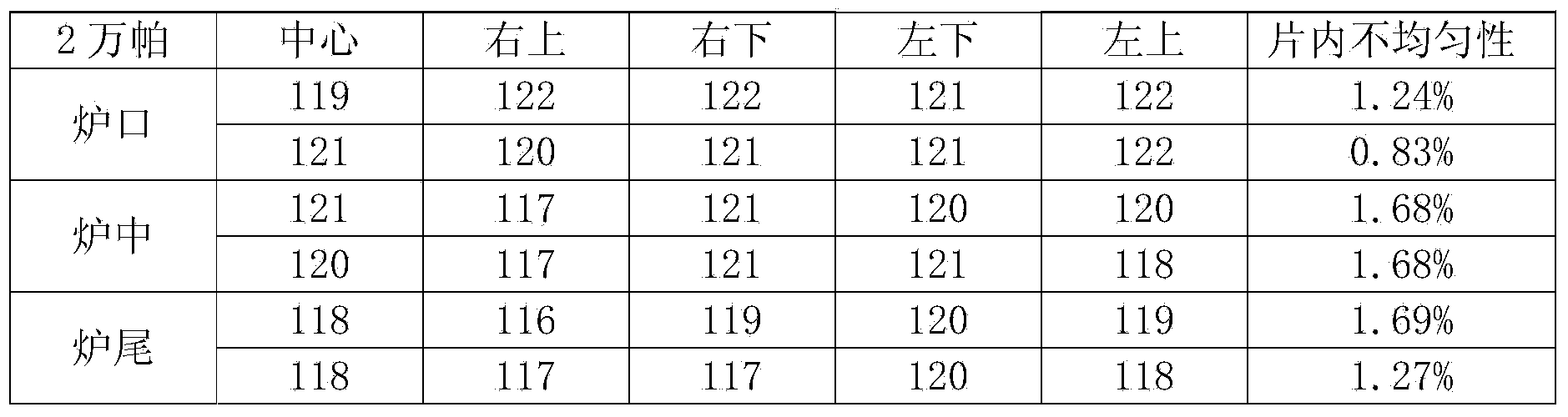

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment the present invention will be further described.

[0028] The present invention provides a decompression diffusion process for preparing high-resistivity cells. Relying on a decompression diffusion furnace, it can be any existing decompression diffusion furnace. This embodiment is preferably the high-temperature decompression diffusion furnace disclosed in 202989354U. Phosphorus diffusion and related processes are carried out on silicon wafers.

[0029] In a typical case, the diffusion process is carried out under the pressure of 20,000 Pa. The specific steps are as follows:

[0030] (1) Carry out the preparation process, insert the textured silicon wafer into the narrow-spaced quartz boat, and the interval between the adjacent silicon wafer slots of the quartz boat is 2.38mm.

[0031] (2) Carry out the process of constant temperature and depressurization, the temperature is controlled at 810°C, 3000sccm of large nitrogen is introdu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com