Germanium (Ge) base tri-gate device and manufacturing method thereof

A device, germanium-based technology, applied in the structural form and manufacturing field of germanium-based (Ge) tri-gate (Tri-Gate) transistors, can solve problems such as difficult to control oxidation time, cumbersome operation, and influence on experimental efficiency, and achieve reduction of oxygen The effects of vacancy defects, increased dielectric constant, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical content of the present invention, specific embodiments are described below in conjunction with the accompanying drawings.

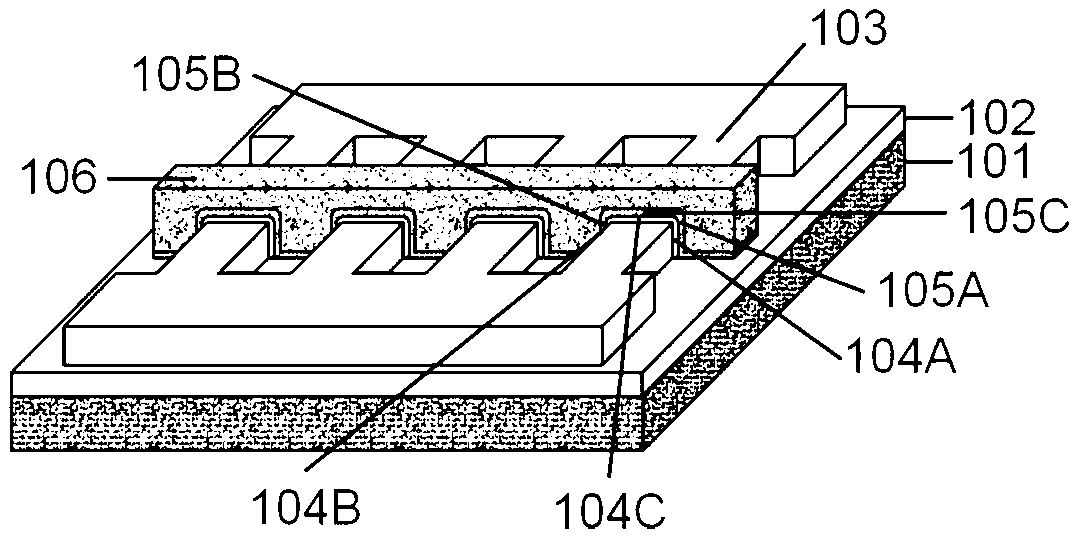

[0026] figure 1 It is a schematic diagram of the overall structure of a high-performance Ge-based tri-gate device. The germanium-based tri-gate device includes a single crystal silicon substrate 101, a silicon dioxide insulating layer 102, a single crystal germanium body 103, a germanium oxide transition layer 104A, 104B, 104C, a gate dielectric layer 105A, 105B, 105C and a gate electrode 106 A silicon dioxide insulating layer is formed on a single crystal silicon substrate, a single crystal germanium body is formed on the silicon dioxide insulating layer, and a germanium oxide transition layer is formed on three sides of the single crystal germanium body and surrounds the single crystal germanium body. On three sides, the gate dielectric layer is formed on the germanium oxide transition layer and surrounds...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com