Vacuum switch tube

A vacuum switch tube and shell technology, applied in electrical switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve problems such as limiting the withstand voltage strength, and achieve the effect of high withstand voltage strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

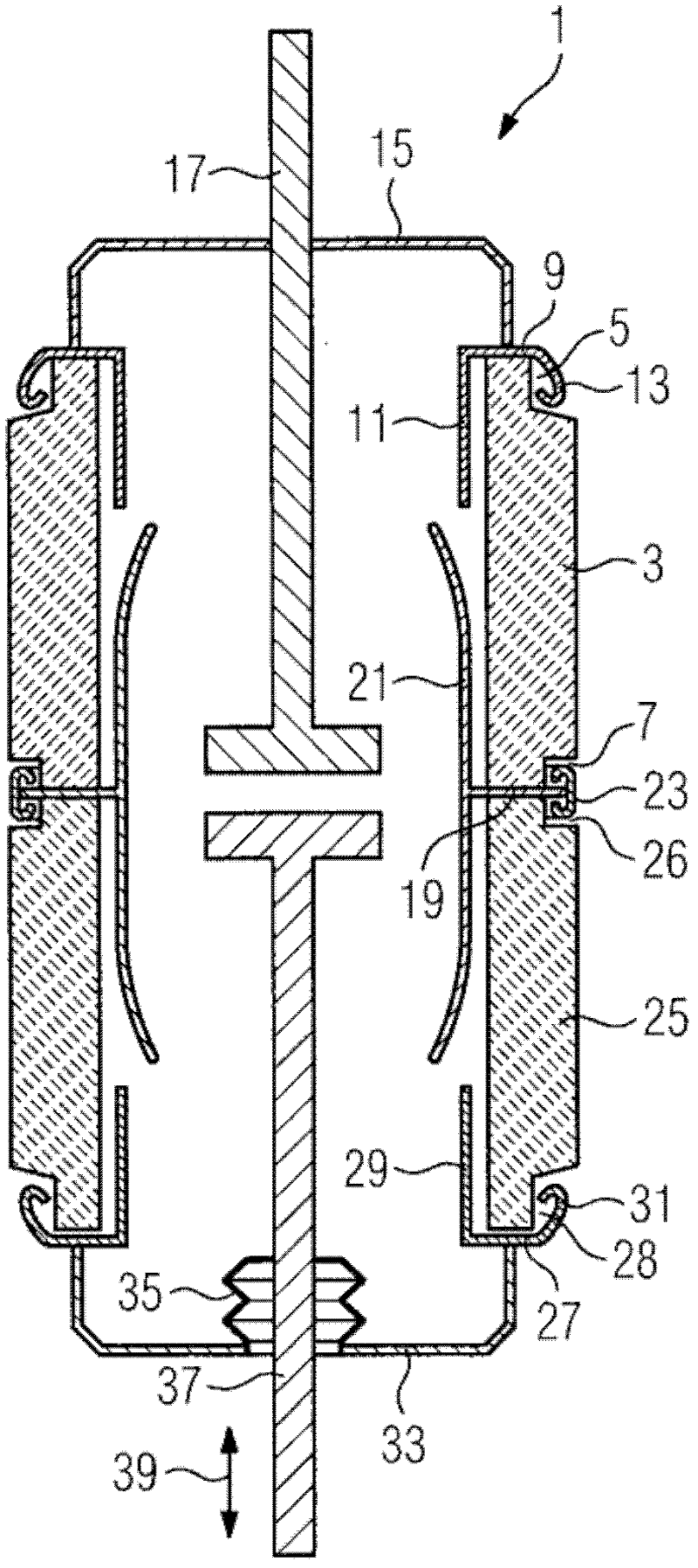

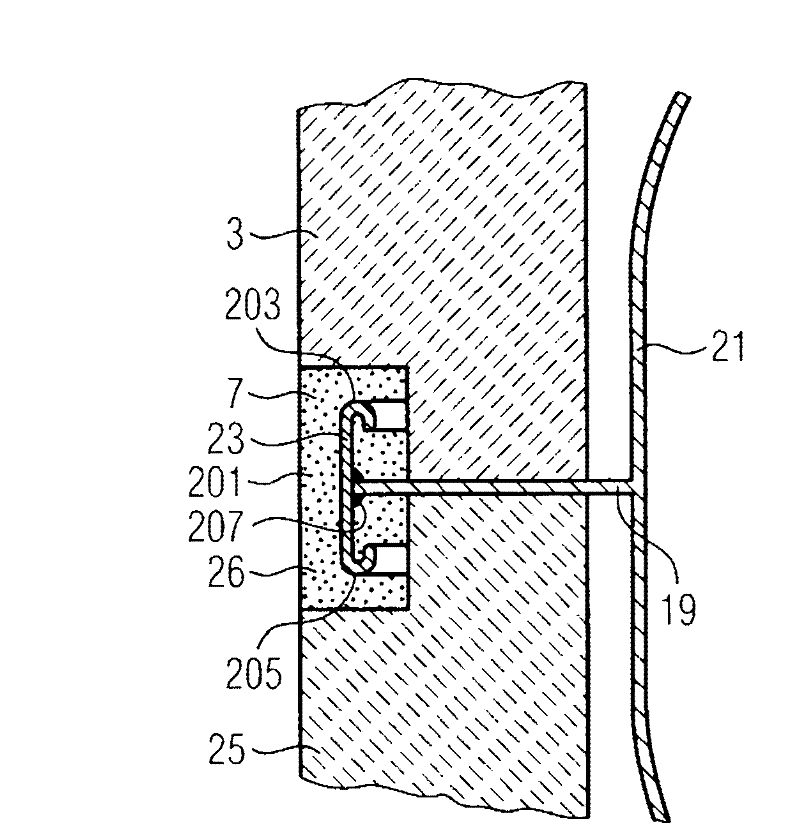

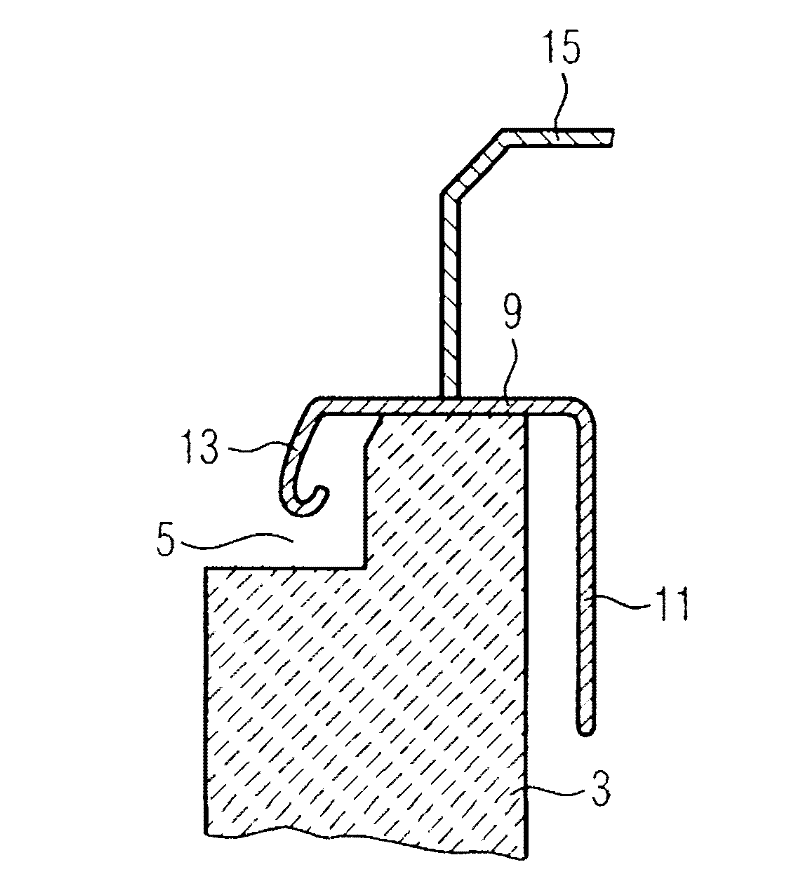

[0020] figure 1 A cross-sectional view of the vacuum interrupter 1 is shown. Such a vacuum interrupter 1 has an essentially cylindrical, electrically insulating first housing part 3 made of ceramic. The first housing part 3 has a substantially hollow-cylindrical shape and has a first recess 5 at one end face and a second recess 7 at the other end face. One end face of the first housing part 3 is vacuum-tightly connected to the first metal part 9 , eg vacuum-tightly welded. The first metal part 9 has a flange-shaped metal ring with a vapor barrier 11 inside the vacuum interrupter and a first field control element 13 at its radially outward end. The first metal part 9 is vacuum-tightly connected to the first metal cover 15 . The static contact 17 passes through the first metal cover 15 and is firmly inserted therein, for example by welding.

[0021] The other end face of the first housing part 3 is connected to the second metal part 19 in a vacuum-tight manner. The second m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com