Diffusing process with low temperature, low surface concentration and high sheet resistance

A diffusion process and low-surface technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing the surface recombination rate and reducing the conversion efficiency of silicon wafers of solar cells, so as to reduce the surface recombination rate and improve the efficiency of the battery. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

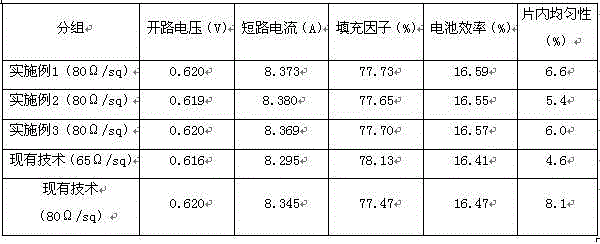

specific Embodiment 1

[0040] (1) Entering the boat: start the diffusion furnace, and put the silicon wafer to be processed into the furnace tube when the temperature in the furnace tube reaches 750°C;

[0041] After the furnace door is closed, the temperature in the furnace tube is raised to a stable temperature of 750°C, the atmosphere in the furnace is a nitrogen atmosphere, and the nitrogen gas is continuously introduced until the diffusion is completed, and the flow rate is 6L / min;

[0042] (2) Oxidation: At a temperature of 750°C, pass O into the furnace tube 2 , and the time is 15 minutes, forming an oxide film on the surface of the silicon wafer to protect the surface of the silicon wafer and increase the uniformity of diffusion;

[0043] (3) The first step of deposition: At a temperature of 750 ° C, 900 sccmN is passed into the furnace tube 2 POCl 3 , the time is 20min, to complete the constant surface concentration diffusion at low temperature;

[0044] (4) The second step of deposition...

specific Embodiment 2

[0048] (1) Entering the boat: start the diffusion furnace, and put the silicon wafer to be processed into the furnace tube when the temperature in the furnace tube reaches 760°C;

[0049] After closing the furnace door, the temperature in the furnace tube was raised to a stable temperature of 760°C, the atmosphere in the furnace was a nitrogen atmosphere, and the nitrogen gas continued to flow in until the diffusion was completed, with a flow rate of 15 L / min;

[0050] (2) Oxidation: At a temperature of 760°C, pass O into the furnace tube 2 , the time is 10min, a layer of oxide film is formed on the surface of the silicon wafer to protect the surface of the silicon wafer and increase the uniformity of diffusion;

[0051] (3) The first step of deposition: at a temperature of 760 ° C, 800 sccmN is passed into the furnace tube 2 POCl 3 , the time is 15min, to complete the constant surface concentration diffusion at low temperature;

[0052] (4) The second step of deposition: r...

specific Embodiment 3

[0056] (1) Entering the boat: start the diffusion furnace, and when the temperature in the furnace tube reaches 770°C, put the silicon wafer to be processed into the furnace tube; after closing the furnace door, stabilize the temperature in the furnace tube at 770°C, and the atmosphere in the furnace is nitrogen Atmosphere, nitrogen gas is continuously fed until the diffusion is completed, and the flow rate is 10L / min;

[0057] (2) Oxidation: At a temperature of 770°C, pass O into the furnace tube 2 , and the time is 7 minutes, forming an oxide film on the surface of the silicon wafer to protect the surface of the silicon wafer and increase the uniformity of diffusion;

[0058] (3) The first step of deposition: at a temperature of 770 ° C, 600 sccmN is passed into the furnace tube 2 POCl 3 , the time is 10min, to complete the constant surface concentration diffusion at low temperature;

[0059] (4) The second step of deposition: raise the temperature in the furnace tube to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com