A kind of catalyzed infiltration method for improving low-temperature gas carburizing speed of austenitic stainless steel

A technology of austenitic stainless steel and low-temperature gas, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., to achieve the effects of reducing production costs, accelerating diffusion rate, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

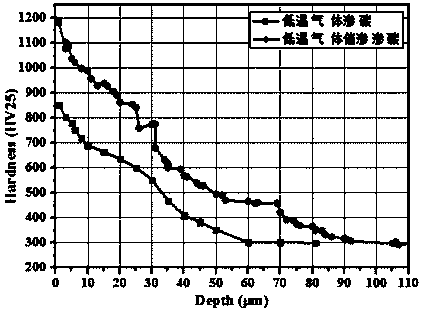

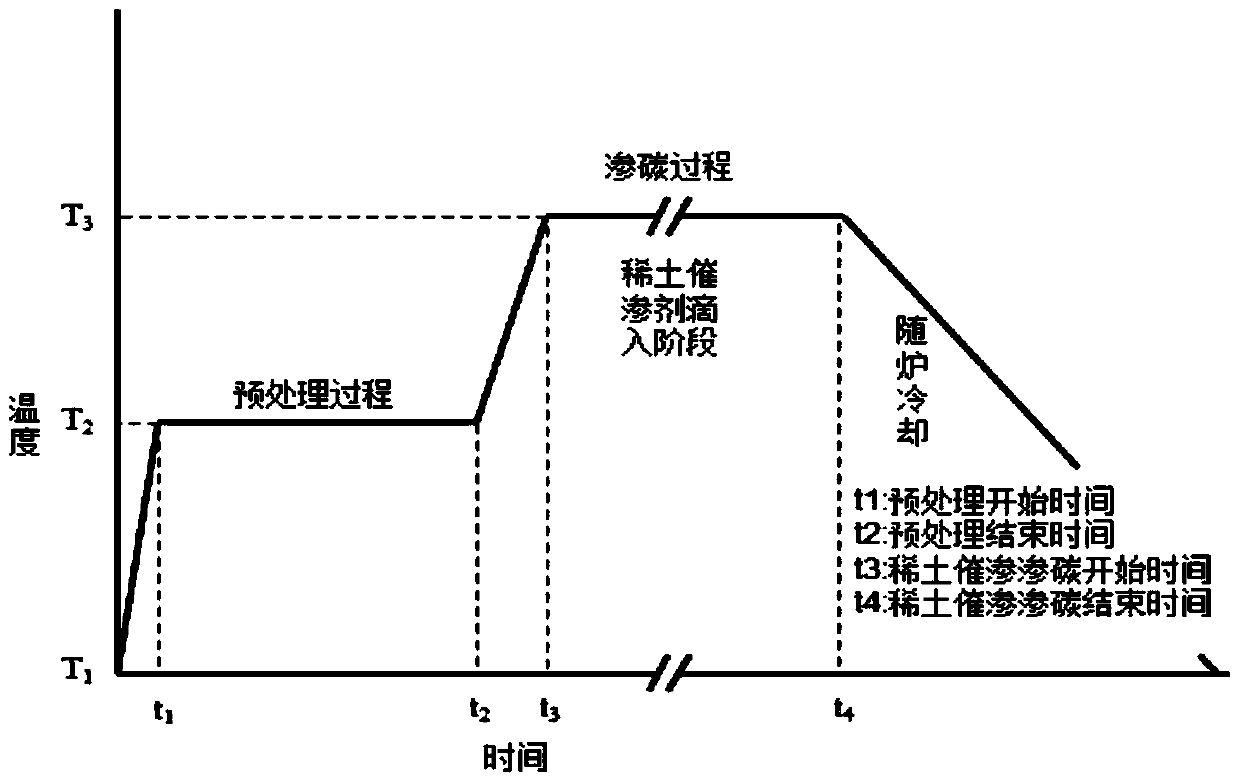

[0029] Example 1: Carburization and carburization of AISI316 austenitic stainless steel by low-temperature gas lanthanum chloride.

[0030] 1. Prepare gas phase carburizing agent:

[0031] According to the volume fraction of gas phase carburizing agent, the composition is (35%~15%)CO+10%H 2 +(55%~75%)N 2 , to prepare gas-phase carburizing agent, the mass of the obtained gas-phase carburizing agent per unit volume is 1.13g / L.

[0032] 2. Preparation of liquid-phase rare earth permeation agent:

[0033] A liquid-phase rare earth permeation agent composed of rare earth chloride and methanol solution, the rare earth chloride uses lanthanum chloride (LaCl) with a molecular weight of about 246 3 ); under stirring condition, 20g lanthanum chloride is completely dissolved in 100ml methanol, is mixed with liquid phase rare earth osmotic agent, obtains the unit volume liquid phase rare earth osmotic agent quality and is: lanthanum chloride 0.2g / ml, corresponding to lanthanum Element 0...

Embodiment 2

[0041] Example 2: AISI316 austenitic stainless steel is infiltrated by low-temperature gas lanthanum chloride, and carburized in a short time.

[0042] 1. Prepare gas phase carburizing agent:

[0043] According to the volume fraction of gas phase carburizing agent, the composition is (35%~15%)CO+10%H 2 +(55%~75%)N 2 , to prepare gas-phase carburizing agent, the mass of the obtained gas-phase carburizing agent per unit volume is 1.13g / L.

[0044] 2. Preparation of liquid-phase rare earth permeation agent:

[0045] A liquid-phase rare earth permeation agent composed of rare earth chloride and methanol solution, the rare earth chloride uses lanthanum chloride (LaCl) with a molecular weight of about 246 3 ); under stirring condition, 20g lanthanum chloride is completely dissolved in 100ml methanol, is mixed with liquid phase rare earth osmotic agent, obtains the unit volume liquid phase rare earth osmotic agent quality and is: lanthanum chloride 0.2g / ml, corresponding to lantha...

Embodiment 3

[0053] Example 3: AISI316 austenitic stainless steel is catalyzed and carburized by low-temperature gas mixed with rare earth chloride.

[0054] 1. Prepare gas phase carburizing agent:

[0055] According to the volume fraction of gas phase carburizing agent, the composition is (35%~15%)CO+10%H 2 +(55%~75%)N 2 , to prepare gas-phase carburizing agent, the mass of the obtained gas-phase carburizing agent per unit volume is 1.13g / L.

[0056] 2. Preparation of liquid-phase rare earth permeation agent:

[0057] The liquid-phase rare earth penetrating agent composed of rare earth chloride and methanol solution, the rare earth chloride adopts mixed rare earth chloride (29.3% LaCl 3 , 50.4% CeCl 3 , 5.1% PrCl 3 , 15.1% NdCl 3 ) Average molecular weight 247; Under stirring condition, 20g above-mentioned mixed rare earth chlorides are completely dissolved in 100ml methanol, are mixed with liquid phase rare earth osmotic agent, obtain the quality of unit volume liquid phase rare ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com