A vacuum carburizing method with temperature reduction and acceleration

A vacuum carburizing and speed-up technology, applied in the direction of solid-state diffusion coating, coating, metal material coating technology, etc., can solve the problems of high carburizing temperature, uneven carburizing layer structure, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific implementation mode one: the vacuum carburizing treatment method of cooling and increasing speed in this implementation mode is implemented according to the following steps:

[0021] 1. Base material preparation: Surface polishing and cleaning treatment are carried out on the base material in turn to obtain the cleaned base material;

[0022] 2. Compound pretreatment:

[0023] a. Mixing powder: using a ball mill to mix the rare earth oxide powder and the hard ceramic powder to obtain a mixed powder, the content of the rare earth oxide in the mixed powder is 5wt% to 20wt%;

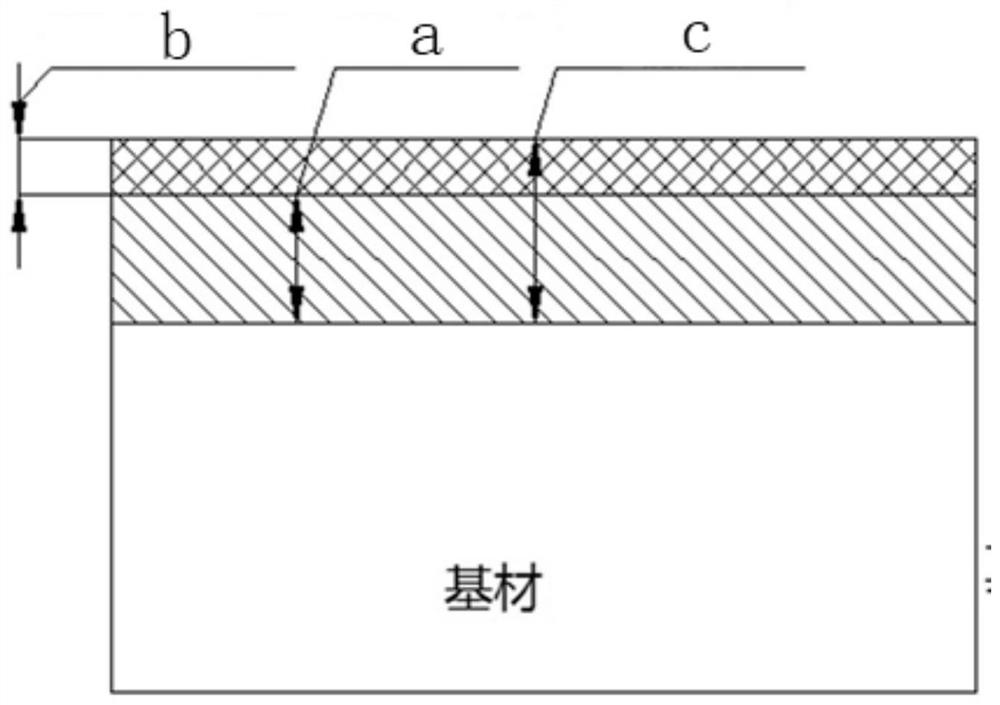

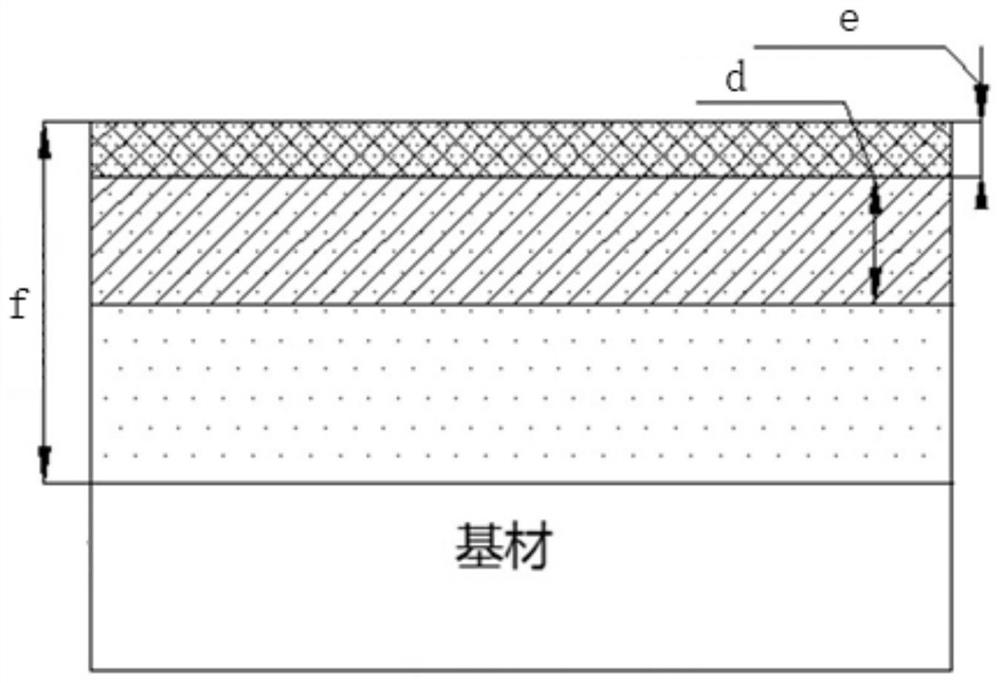

[0024] b. Supersonic particle bombardment: the mixed powder is loaded into the supersonic particle bombardment equipment, and the cleaned substrate is placed under the gun head of the supersonic particle bombardment equipment for supersonic particle bombardment treatment, and the mixed powder is controlled during the supersonic particle bombardment process The vertical spraying distance is ...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the base material in step 2 is low-carbon steel (carbon content<0.25%).

[0029] The low-carbon steel described in this embodiment can be 17CrNiMo6, 18Cr2Ni4WA, 12Cr2Ni4A and the like.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the rare earth oxide described in step two is La 2 o 3 or CeO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com