A carburizing method for suppressing reticular carbide structure of high chromium and high cobalt carburizing steel and increasing carburizing speed

A network carbide and carburizing steel technology, which is applied in the direction of liquid chemical plating, solid diffusion coating, vacuum evaporation plating, etc., can solve the problems of poor fatigue resistance and high material brittleness, so as to improve carburizing speed, Effect of reducing production cost and shortening carburizing heat treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

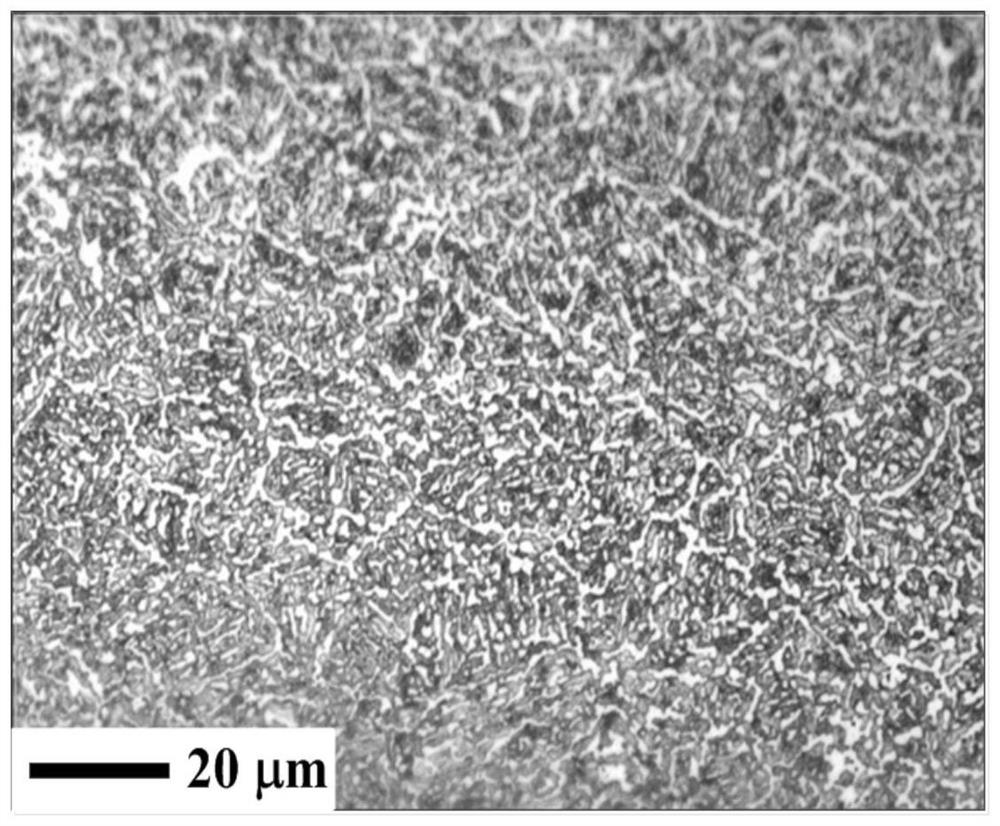

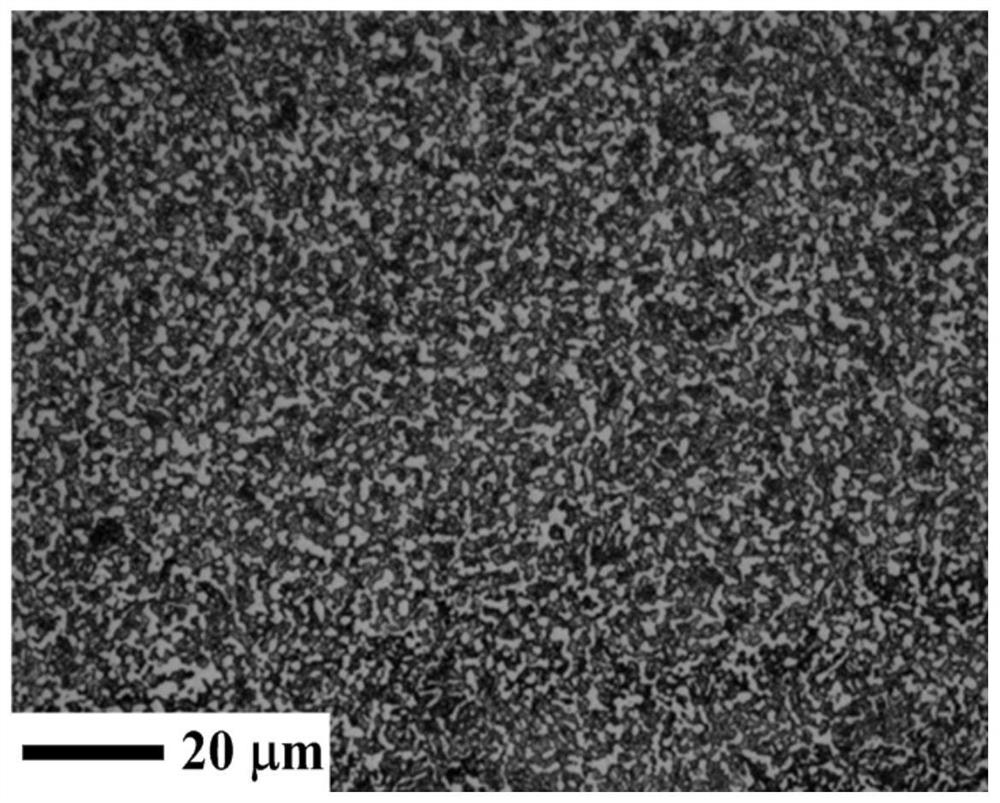

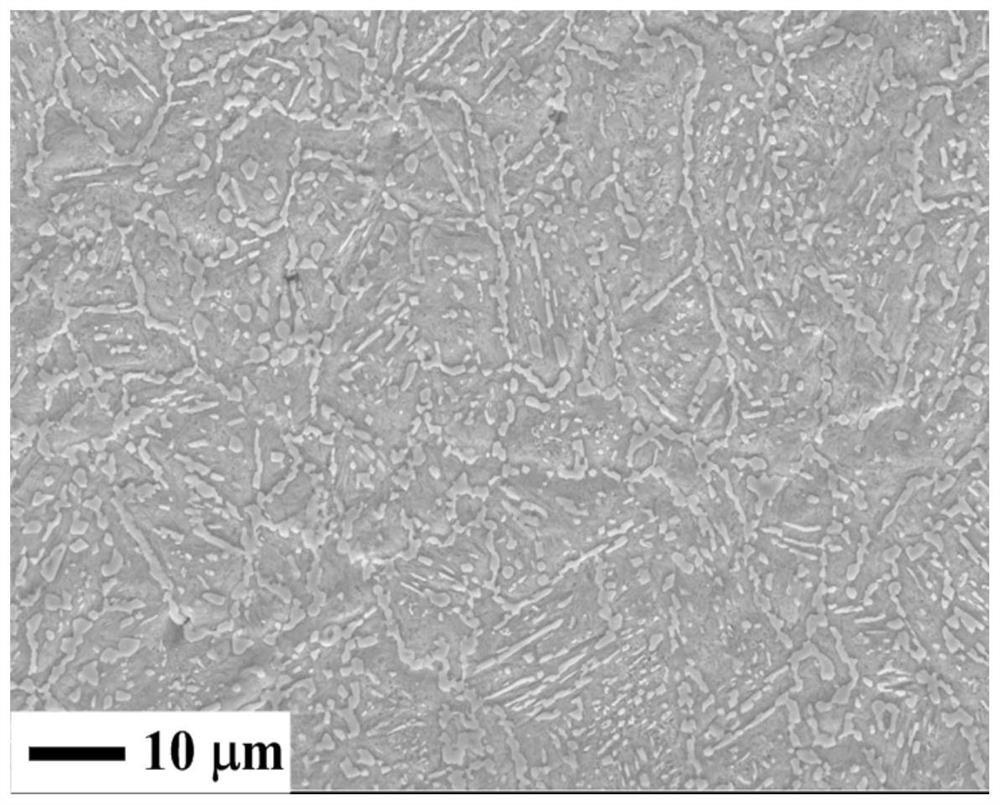

[0025] Specific embodiment one: present embodiment is a kind of carburizing method that suppresses reticular carbide structure of high chromium and high cobalt carburizing steel and improves carburizing speed, specifically carries out according to the following steps:

[0026] 1. Coating: Coating a metal film on the surface of high chromium and high cobalt carburizing steel, controlling the thickness of the metal film to be 1 μm to 50 μm to obtain a coated workpiece;

[0027] 2. Carburizing: use vacuum pulse carburizing technology to carburize the coated workpiece obtained in step 1, and control the carburizing temperature at 800°C to 1000°C; complete the inhibition of the reticular carbide structure of high chromium and high cobalt carburizing steel A carburizing method that increases the carburizing speed.

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that the coating method in step 1 is vacuum evaporation, magnetron sputtering coating, multi-arc ion coating, electroplating or electroless plating. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the coating process in step one is: adopt the method of direct current electroplating to coat a layer of alloy film on the surface of high chromium and high cobalt carburized steel, wherein the electroplating solution Composition: nickel chloride concentration is 0.2mol / L, nickel sulfate concentration is 0.5mol / L, ferrous sulfate concentration is 0.5mol / L, boric acid concentration is 0.5mol / L, control current density is 10mA / cm 2 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com