Enriched energizer for low-temperature gas carburization of large-sized high-speed and heavy-duty thin-walled gear

A low-temperature gas, large-scale technology, used in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of complex infiltrating agent formulation, high cracking temperature, blockage of pipelines, etc., and increase the carbon diffusion coefficient. , The effect of reducing carburizing temperature and avoiding pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

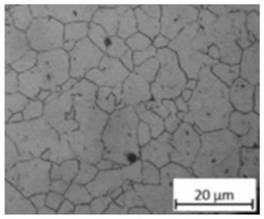

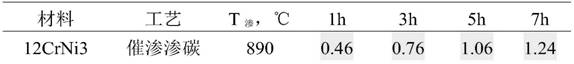

[0011] The permeation agent comprises 6% by weight of rare earth, 12% of carbon tetrachloride, 3% of lithium zirconate and the balance of isomeric alcohol. The rare earth is composed of 90% lanthanum oxide and 10% cerium oxide. Weigh the raw materials according to the above ratio, mix them uniformly to form a penetrating agent, and dilute them with methanol at a ratio of 1:10. Put the 12CrNi3 workpiece with the surface passivation film removed into the carburizing furnace, vacuumize, feed the carburizing gas, heat the carburizing furnace, and start the carburizing treatment with the infusion agent dripping system at the same time, and set the carbon potential to 1.05%. Two carburizing temperatures of 890 and 930°C are designed, and four carburizing times are 1h, 3h, 5h and 7h respectively. After the carburizing is completed, the depth of the carburizing layer is measured by metallographic method. After detection and analysis, the depth of the carburized layer of this materia...

Embodiment example 2

[0017] The permeation agent includes 6% rare earth by weight, 12% carbon tetrachloride, 3% lithium zirconate, and the balance of isomeric alcohol. The rare earth is composed of 90% lanthanum oxide and 10% cerium oxide. Weigh the raw materials according to the above ratio, mix them uniformly to form a penetrating agent, and dilute them with methanol at a ratio of 1:10. Put the 18CrNiMo7 workpiece with the surface passivation film removed into the carburizing furnace, vacuumize, feed the carburizing gas, heat the carburizing furnace, and start the carburizing treatment with the infusion agent dripping system at the same time, and set the carbon potential to 1.05%. Two carburizing temperatures of 890 and 930°C are designed, and four carburizing times are 1h, 3h, 5h and 7h respectively. After the carburizing program is completed, the depth of the carburizing layer is measured by metallographic method, and the infiltration effect is shown in Table 1.

Embodiment example 3

[0019] The permeation agent includes 6% rare earth by weight, 12% carbon tetrachloride, 3% lithium zirconate, and the balance of isomeric alcohol. The rare earth is composed of 90% lanthanum oxide and 10% cerium oxide. Weigh the raw materials according to the above ratio, mix them uniformly to form a penetrating agent, and dilute them with methanol at a ratio of 1:10. Put the 20Cr2Ni4A workpiece with the surface passivation film removed into the carburizing furnace, vacuumize, feed the carburizing gas, heat the carburizing furnace, and start the carburizing treatment by turning on the infiltrating agent dripping system at the same time, setting the carbon potential to 1.05%. Two carburizing temperatures of 890 and 930°C were designed, and four carburizing times were 1h, 3h, 5h and 7h. After completing the carburizing procedure, the metallographic method was used to measure the depth of the carburizing layer, and the infiltration effect is shown in Table 1.

[0020] Table 1 R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com