Neodymium-iron-boron permanent magnet material prepared from Dy and preparation method of neodymium-iron-boron permanent magnet material

A permanent magnet material, neodymium iron boron technology, applied in the field of materials, can solve the problems of reducing the magnetic moment of iron atoms, complexity, and reduction of remanence, and achieve the effect of improving coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

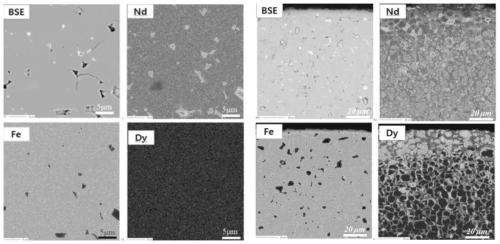

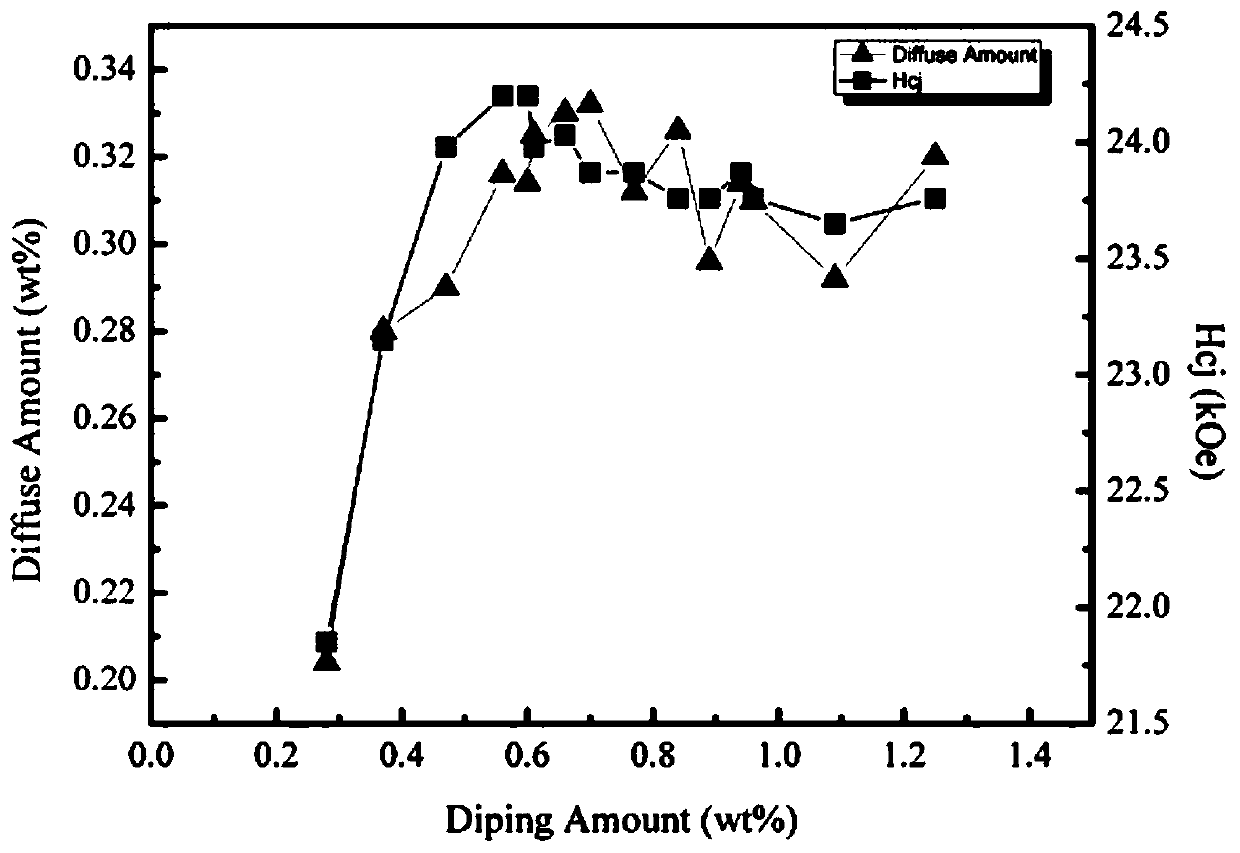

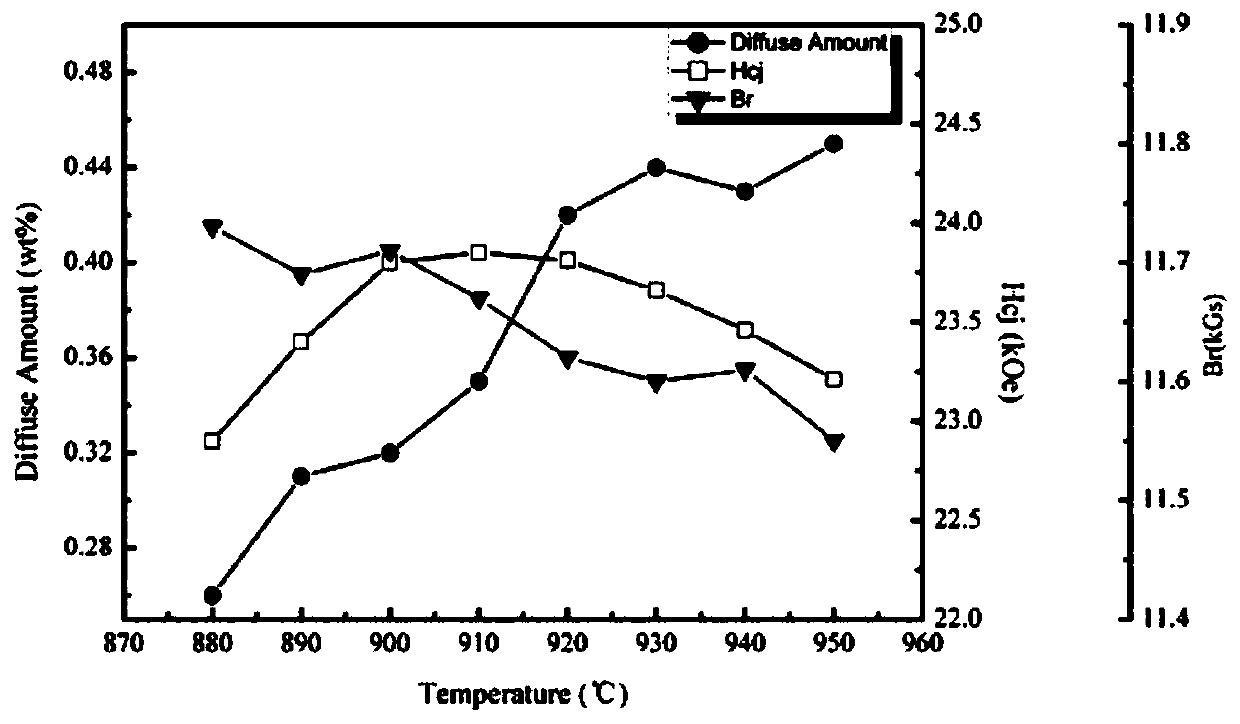

[0035] Preparation of Dy grain boundary diffusion in NdFeB magnets with heavy rare earth wrapped Nd 2 Fe 14 The method for the core-shell structure permanent magnet material of B phase, the process parameter of each magnetic performance optimum comprises following main steps:

[0036] (1) Take the NdFeB regenerative magnet sample. According to the mold specification of the sintering furnace: 12.5mm×12.5mm×4mm, and considering that the thickness of the sample increases by about 0.5mm after coating, the sample is processed into 12.5mm× 12.5mm×3.5mm sample, where the orientation direction is used as the diffusion direction;

[0037] (2) After the sample is surface treated (pickling, degreasing, derusting), it is dried for use;

[0038] (3) Dysprosium fluoride (DyF 3 ) as a diffusion source, after the dysprosium fluoride precipitate is dried, it is made into a suspension with anhydrous alcohol in a certain proportion, and is ready for use;

[0039] (4) Coat the suspension on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com