Method for quickly producing porcelain pot with different colors on inner surface and outer surface

A technology of internal and external surfaces and production methods, applied in the field of ceramics, can solve the problems of no clear dividing line of enamel color, unsatisfactory product effect, single color of ceramic pot, etc., achieve clear and obvious dividing line, shorten production cycle, and save firing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

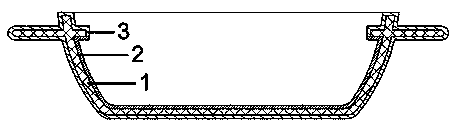

Image

Examples

Embodiment 1

[0019] Example 1: (1) After the porcelain clay is molded into a ceramic pot body through conventional ingredients, ball milling, sieving, dehydration, aging, smelting, and grouting in the ceramic production process, it is then bisque fired at 750°C for 5 hours;

[0020] (2) Mix 20% of gasoline and 80% of wax by weight percentage, and heat to 60°C to make spacer fluid for later use;

[0021] (3) According to weight percentage, 6% alumina, 42.973% petalite feldspar, 16% quartz, 8% talc, 6% calcium oxide, 9% kaolin, 9% feldspar, 0.004% rhodium, 0.015% nickel, tungsten 0.005%, molybdenum 0.003%, iron oxide 3%, after mixing, put it into a ball mill, add clear water, the weight ratio of the above mixed materials and clear water is 1:1, and the slurry passed through the ball mill passes through a 325 mesh sieve to make an inner glaze for later use;

[0022] According to weight percentage, alumina 6%, petalite feldspar 42.939%, quartz 16%, talc 8%, calcium oxide 6%, kaolin 9%, feldspa...

Embodiment 2

[0025] Example 2: The difference from Example 1 is that in the step (4), after immersing the ceramic pot body in the outer glaze for glazing and drying it, first place the ceramic pot body in a -6°C freezer for 6 minutes, and then put the Place the ceramic pot body in an oven at 25°C for 6 minutes; then place the ceramic pot body in a -18°C freezer for 12 minutes, then place the ceramic pot body in an oven at 45°C for 12 minutes, and finally enter the step ( 5) production process, the product of embodiment 2 is obtained. The glaze texture of the product of Example 2 is firmer, and the glaze surface is scratched with a paper cutter, without leaving any knife marks, and the glossiness is better than that of the product of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com