Method for connecting hollow glass bodies and discharge vessel

A technology of hollow glass and discharge vessel, applied in the field of discharge vessel, can solve the problems of impossibility, wipe-out cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

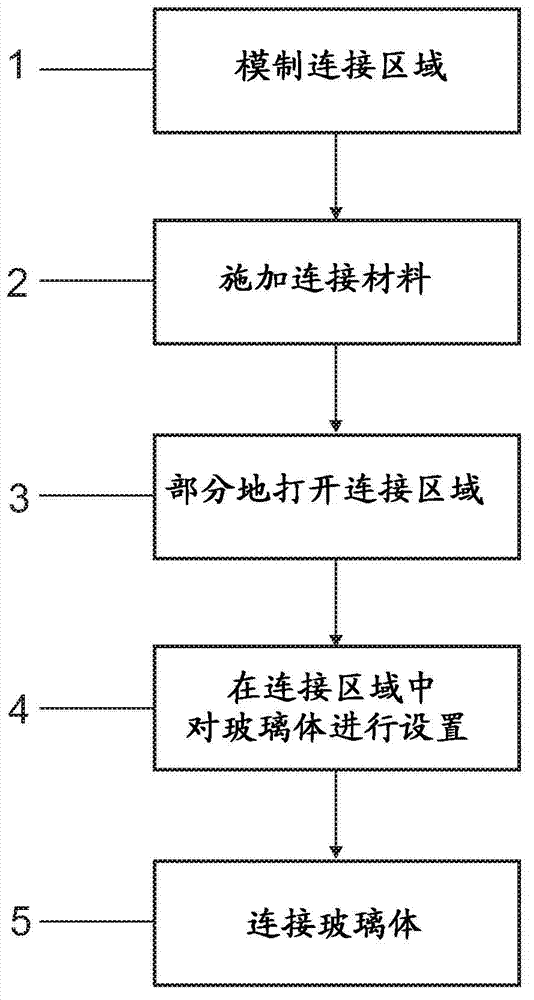

[0046] figure 1 A schematic diagram showing a flow diagram of an embodiment of a method for producing a fluid connection between hollow glass bodies. The method according to an embodiment comprises the steps of respectively molding the connecting region (1) at the glass body, applying the connecting material (2), at least partially opening the connecting region (3), forming a contact with the glass body in the region of the connecting region (4) Make settings and attach glass body (5). It is also possible to insert other advantageous intermediate steps between the steps of the illustrated embodiment or to modify the steps. In particular, the fifth step ( 5 ) can comprise joining the glass bodies via the connecting material, so that the glass bodies are each fused to the connecting material and the connecting materials are fused to each other.

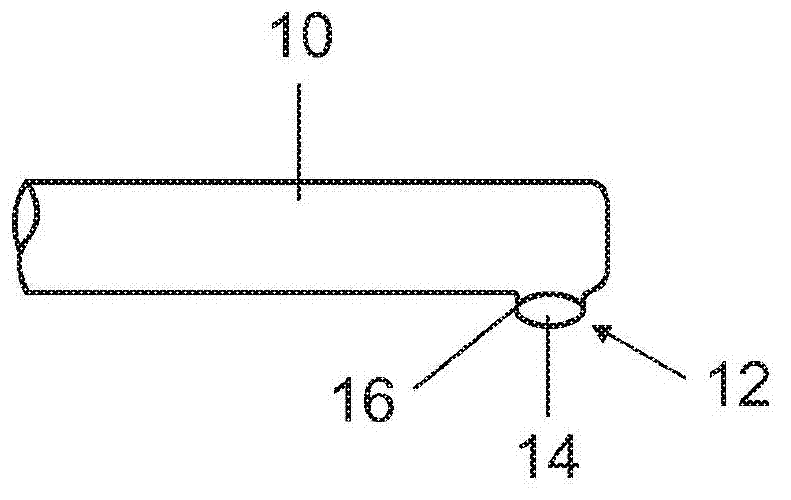

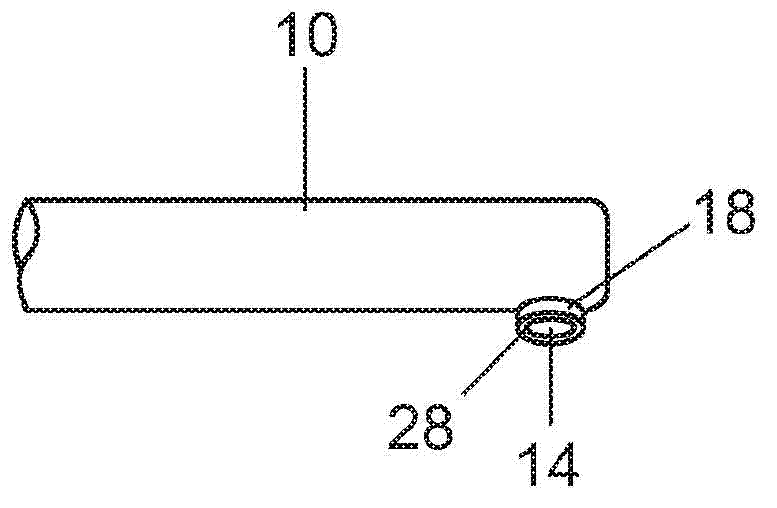

[0047] according to Figures 2a to 2c A first embodiment of the method will be explained in detail. Figure 2a A schematic illustr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com