Polyethylene-polystyrene foam and preparation method thereof

A polystyrene foam, polystyrene technology, applied in the field of polyethylene-polystyrene foam and its preparation, can solve the problems affecting processing and foam product performance, poor strength, poor toughness, etc., to avoid homopolymerization and polymerization. Side reactions such as cross-linking and/or degradation, uniform concentration distribution, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

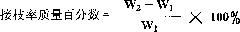

Method used

Image

Examples

Embodiment 1

[0021] Example 1 Low-density polyethylene was pre-irradiated with β rays on an electron accelerator device under an air atmosphere, and the pre-irradiation dose was 5 kGy.

[0022] 5 parts by mass of pre-irradiated low-density polyethylene, 70 parts by mass of deionized water, 3.3 parts by mass of styrene, 0.08 parts by mass of sodium dodecylbenzenesulfonate, and 0.05 parts by mass of calcium phosphate powder , 0.08 parts by mass of ferrous chloride were added to a reactor equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen gas introduction tube and a heating device, and nitrogen gas was introduced, heated, stirred, and maintained at 50° C. for 1 hour, and the reactor was The temperature of the inner liquid is raised to 80°C, and the suspension grafting reaction is carried out. After 8 hours of reaction, the temperature is lowered to 30°C, and 0.099 parts by mass of pentane foaming agent is added into the reactor, sealed, and the temperature is raised to 110°...

Embodiment 2

[0028] Example 2 An ethylene-1-butene copolymer with a butene mass percentage of 5% was placed in an air atmosphere at 60 The Co device is pre-irradiated with γ-rays, and the pre-irradiation dose is 30kGy.

[0029] 12 parts by mass of pre-irradiated ethylene-1-butene copolymer, 105 parts by mass of deionized water, 7.5 parts by mass of styrene, 1 part by mass of sodium dodecylbenzenesulfonate, silicon dioxide Add 0.2 parts by mass of powder and 0.5 parts by mass of cuprous chloride into a reactor equipped with a stirrer, thermometer, reflux condenser, nitrogen gas introduction tube and heating device, feed nitrogen gas, heat and stir, and maintain at 50°C for 3 hours , raise the temperature of the liquid in the reactor to 125°C, carry out the suspension grafting reaction, after 10 hours of reaction, cool down to 30°C, add 1.875 parts by mass of pentane blowing agent into the reactor, seal it, and raise the temperature to 125°C, Maintain for 6 hours, lower the temperature to 4...

Embodiment 3

[0030] Example 3 An ethylene-1-octene copolymer with a mass percentage of octene of 9% was pre-irradiated with β rays on an electron accelerator device in an air atmosphere, and the pre-irradiation dose was 45 kGy.

[0031] 12 parts by mass of pre-irradiated ethylene-1-octene copolymer, 70 parts by mass of deionized water, 3.3 parts by mass of styrene, 0.6 parts by mass of sodium lauryl sulfate, and 0.05 parts by mass of titanium dioxide powder Parts, 0.1 parts by mass of ferrous chloride were added to a reactor equipped with a stirrer, a thermometer, a reflux condenser, a nitrogen introduction pipe and a heating device, nitrogen was introduced, heated, stirred, and maintained at 50°C for 1 hour, and the reaction The temperature of the liquid in the vessel was raised to 90°C, and the suspension grafting reaction was carried out. After 8 hours of reaction, the temperature was lowered to 50°C, and 0.165 parts by mass of cyclopentane foaming agent was added to the reactor, sealed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com