Multifunctional emulsion-type salt-tolerant fracturing fluid and production method thereof

An emulsion type, fracturing fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of inability to meet the temperature resistance, salt resistance and crosslinkability of the reservoir, and achieve the maximum energy Chemical utilization, reduction of surface tension and interfacial tension, and excellent drag reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

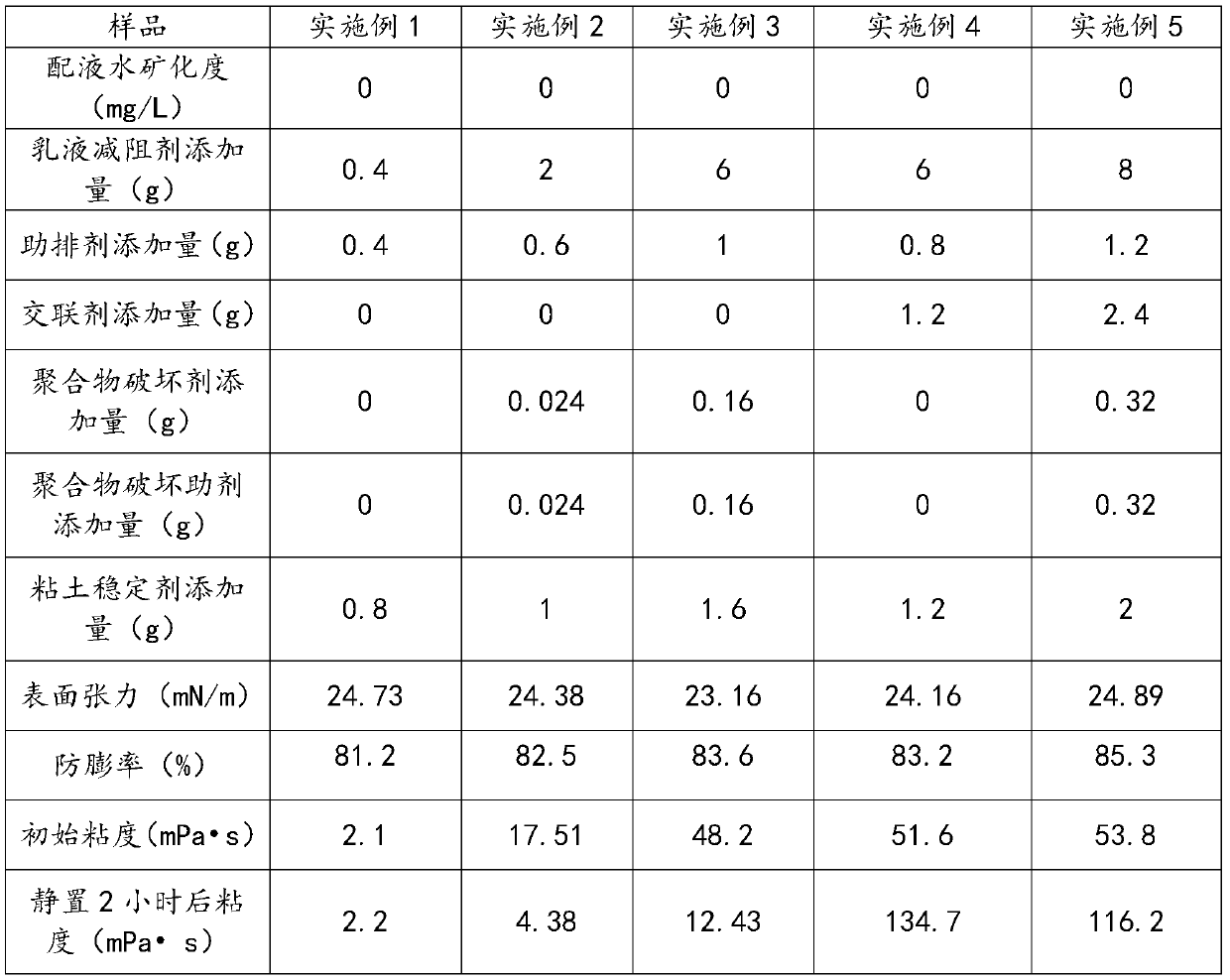

Embodiment 1

[0028] A multifunctional emulsion type salt-resistant fracturing fluid, comprising the following raw materials: 0.4g of emulsion drag reducer, 0.4g of drainage aid, 0.8g of clay stabilizer, and 400g of water; wherein, the emulsion drag reducer is hyperbranched amphoteric Polyacrylamide and its derivatives. The drainage aid is a fluorine-containing drainage aid compounded by a hydrocarbon-based surfactant and a fluorine-containing surfactant. The clay stabilizer is a cationic clay stabilizer and KCl or NH 4 Composite clay stabilizer made of Cl compound.

[0029] The preparation method of the hyperbranched amphoteric polyacrylamide is: adding a certain amount of emulsifier Span-80, emulsifier Span-60, emulsifier OP-10 and solvent Isopar M In the reaction vessel, stir to make it completely dissolved; under the condition of 40-65 ℃ constant temperature water bath, add a certain amount of acrylamide and deionized water to heat-resistant aliphatic hyperbranched polyester, pass N 2...

Embodiment 2

[0032]A multifunctional emulsion type salt-resistant fracturing fluid, including the following raw materials: 2g of emulsion drag reducer, 0.6g of drainage aid, 1g of clay stabilizer, 0.024g of polymer breaker, 0.024g of polymer breakage aid, and 400g of water ; Wherein, the emulsion drag reducer is hyperbranched amphoteric polyacrylamide and its derivatives, and the drainage aid is a fluorine-containing drainage aid compounded by a hydrocarbon-based surfactant and a fluorine-containing surfactant , the clay stabilizer is cationic clay stabilizer and KCl or NH 4 Cl composite compound clay stabilizer; the polymer breaker is benzoyl peroxide; the polymer breaker auxiliary agent is sodium gluconate.

[0033] The preparation method of the hyperbranched amphoteric polyacrylamide is the same as in Example 1.

[0034] The preparation method of the multifunctional emulsion type salt-resistant fracturing fluid is as follows: weighing raw material components according to the formula; a...

Embodiment 3

[0036] A multifunctional emulsion-type salt-resistant fracturing fluid, including the following raw materials: 6g of emulsion drag reducer, 1g of drainage aid, 1.6g of clay stabilizer, 0.16g of polymer breaker, 0.16g of polymer breakage aid, and 400g of water ; Wherein, the emulsion drag reducer is hyperbranched amphoteric polyacrylamide and its derivatives, and the drainage aid is a fluorine-containing drainage aid compounded by a hydrocarbon-based surfactant and a fluorine-containing surfactant , the clay stabilizer is cationic clay stabilizer and KCl or NH 4 Cl composite compound clay stabilizer; the polymer breaker is potassium dichromate; the polymer breaker assistant is hexamethylenetetramine.

[0037] The preparation method of the hyperbranched amphoteric polyacrylamide is the same as in Example 1.

[0038] The preparation method of the multifunctional emulsion type salt-resistant fracturing fluid is the same as that in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com