Adhesive for bonding prefabricated rubber runway

A prefabricated and adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of decreased stability, low cost, insufficient strength, etc., and achieve high stability and not easy to shift , good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] An adhesive for bonding prefabricated rubber runways, including component A and component B stored independently, and component A includes the following components:

[0053] Polyester diol, polyether diol, chain extender, ethyl acetate, propylene glycol methyl ether acetate, catalyst.

[0054] B component is diisocyanate.

[0055] Wherein, polyester glycol is the composite of polyethylene adipate, polybutylene adipate, and the mass ratio of polyethylene adipate, polybutylene adipate is 3:2.

[0056] Wherein, polyether glycol is polyethylene glycol.

[0057] Wherein, the chain extender is 1,4 butanediol.

[0058] Among them, the catalyst is a compound of dibutyltin dilaurate, triethanolamine, bis(2-dimethylaminoethyl) ether, dibutyltin dilaurate, triethanolamine, bis(2-dimethylaminoethyl) ether The mass ratio is 3:5:1.

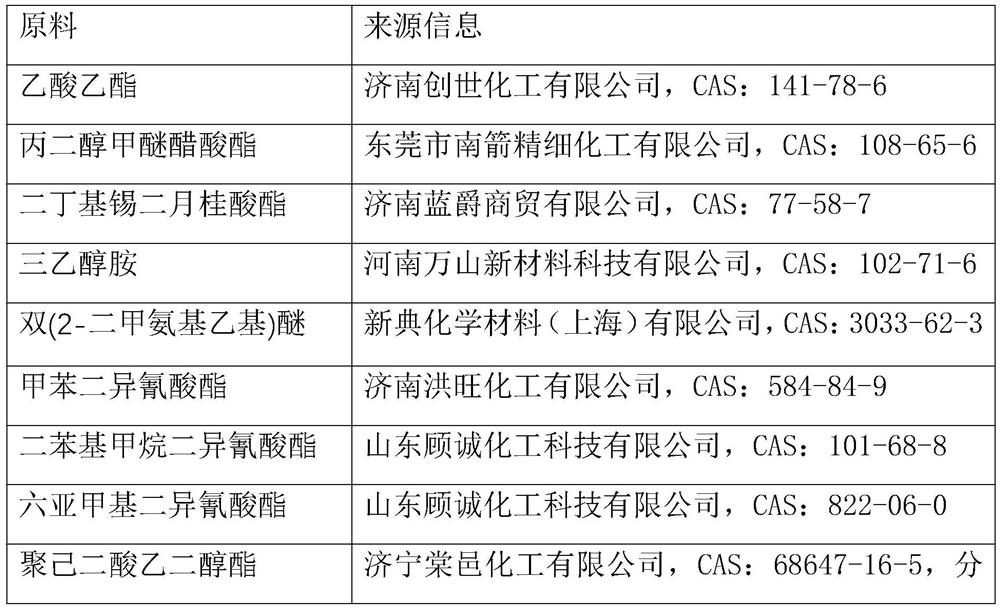

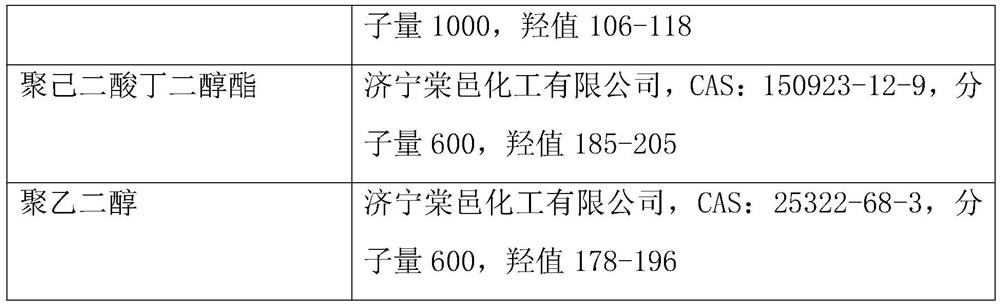

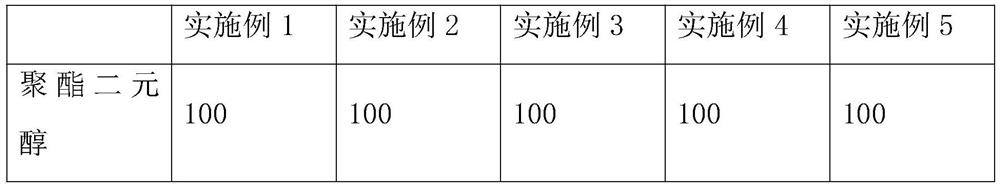

[0059] In Examples 1-5, see Table 2 for the specific input amount (unit: kg) of each component in component A.

[0060] Table 2

[0061]

[00...

Embodiment 1-5

[0066] In embodiment 1-5, the preparation method of A component is as follows:

[0067] Put polyester diol into a stirring tank, heat to 100°C, rotate at 30r / min, keep stirring, then put polyether diol, chain extender, ethyl acetate, propylene glycol methyl ether into polyester diol Acetate and catalyst, rotating at 60r / min, stirring for 5min, cooling to 40°C, subpackaging, pumping out the air in the package to obtain component A.

[0068] In embodiment 1-5, the preparation method of B component is as follows:

[0069] Put the diisocyanate into a stirred tank, heat to 100°C, rotate at 10r / min, stir for 10min, put in nitrogen protection, cool to 40°C, pack separately, and pump out the air in the package to obtain component B.

[0070] By mixing at 100°C, the moisture in each raw material is fully discharged, reducing the influence of moisture on the adhesive.

Embodiment 6

[0072] A prefabricated rubber runway bonding adhesive, compared with embodiment 3, the difference only lies in:

[0073] The mass ratio of dibutyltin dilaurate, triethanolamine and bis(2-dimethylaminoethyl) ether is 1:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com