Electrocatalyst for efficiently decomposing water into hydrogen and oxygen and preparation method of electrocatalyst

An electrocatalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problems of low electron transfer rate, expensive catalyst, low conductivity, etc., and achieve optimized morphology and structure, good Electron conductivity and efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the above-mentioned electrocatalyst for efficiently decomposing water to produce hydrogen and oxygen, the method comprises the following steps:

[0039] Step 1) Mix divalent nickel salt and divalent cobalt salt with hexamethylenetetramine according to a certain ratio, and then add methanol solution and stir evenly to obtain a mixed solution;

[0040] Step 2) placing Ni foam of a certain size and the completely dissolved solution in step 1) in a reaction kettle, and performing a hydrothermal reaction to obtain a precursor product;

[0041] Step 3) After taking out the precursor product obtained in step 2), washing and drying;

[0042] Step 4) Put the precursor product and a certain amount of sulfidation solution in the reaction kettle, and perform a secondary hydrothermal reaction to obtain the product catalyst.

[0043] Further, the hydrothermal growth condition in step 2) is 170-190°C, and the growth time is 8-12h.

[0044] Further, the seco...

Embodiment 1

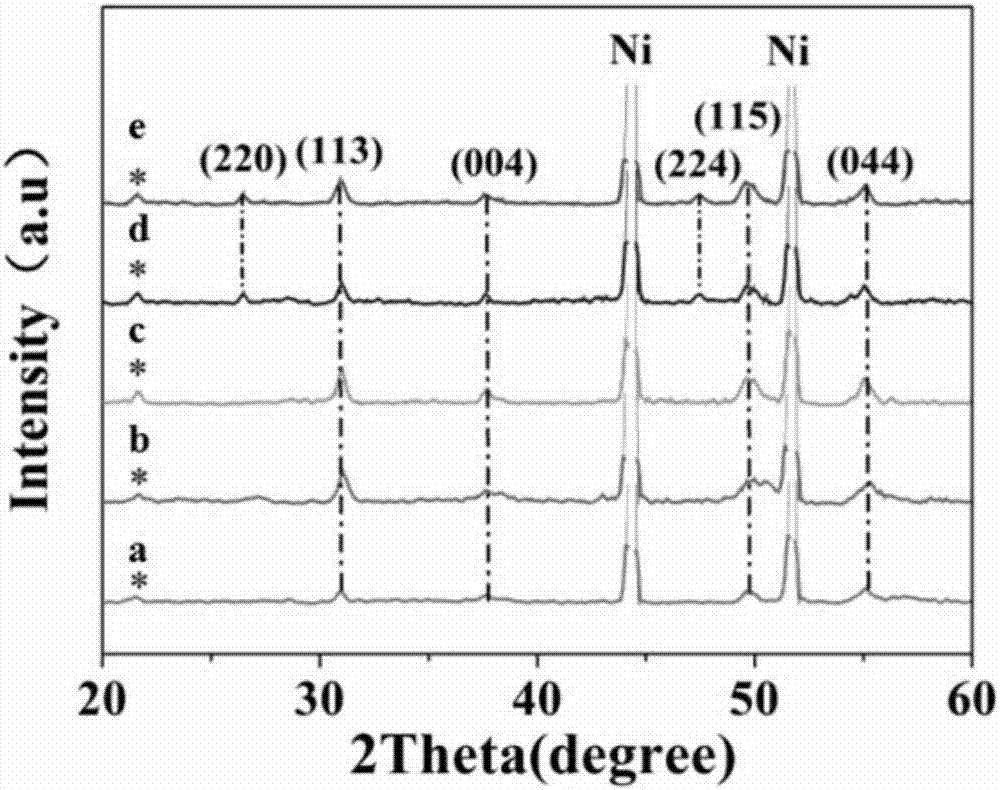

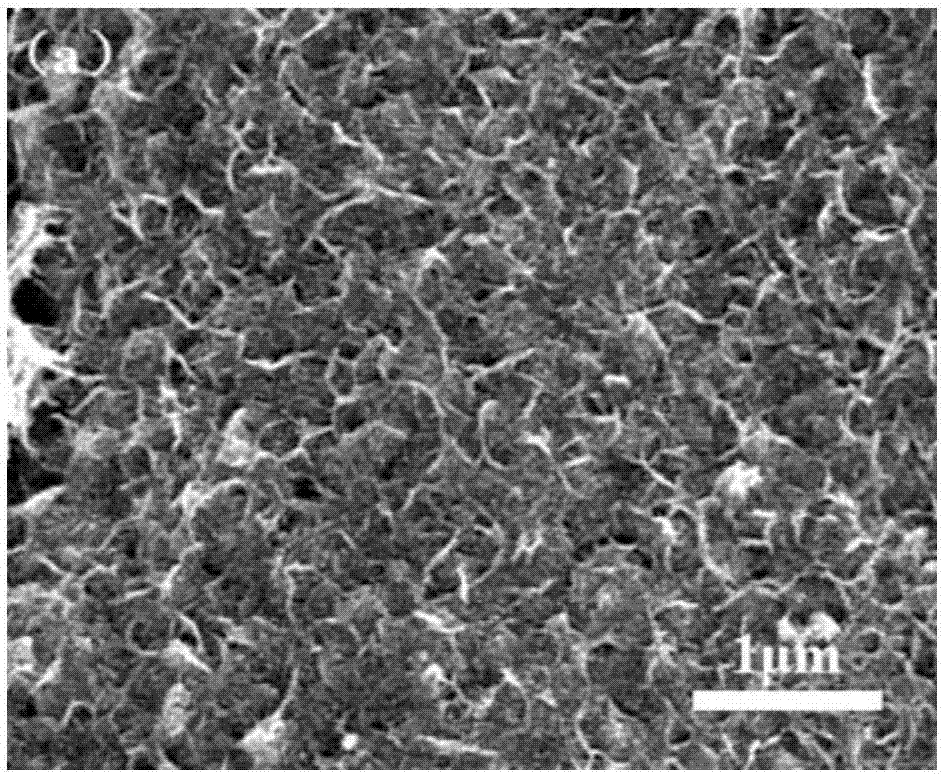

[0049] NiCo 2 S 4 The preparation method of nano sheet electrocatalyst material, comprises the following steps:

[0050] (1) Put a 1cm×1.5cm nickel foam in 1M hydrochloric acid for ultrasonic cleaning for 10 minutes, take it out, rinse it with a large amount of deionized water, and then dry it in a vacuum oven at 40°C.

[0051] (2) Prepare NiCo-LDH growth solution: weigh 14.5 mg of Ni(NO 3 ) 2 ·6H 2 O, 29mg of Co(NO 3 ) 2 ·6H 2 O and 60mg of hexamethylenetetramine were mixed and dissolved in 30mL of methanol, then magnetically stirred for 30min to mix them uniformly to obtain a clear growth solution with an elemental ratio of Ni and Co of 1:2.

[0052] (3) Put the dried Ni foam into a 50 mL reactor, and pour the growth solution slowly so that the filling volume is about 80%. The reaction kettle was sealed in a stainless steel sleeve, and then placed in a blast drying oven for heat treatment. The reaction temperature was kept at 180° C., and the reaction time was 10 h. ...

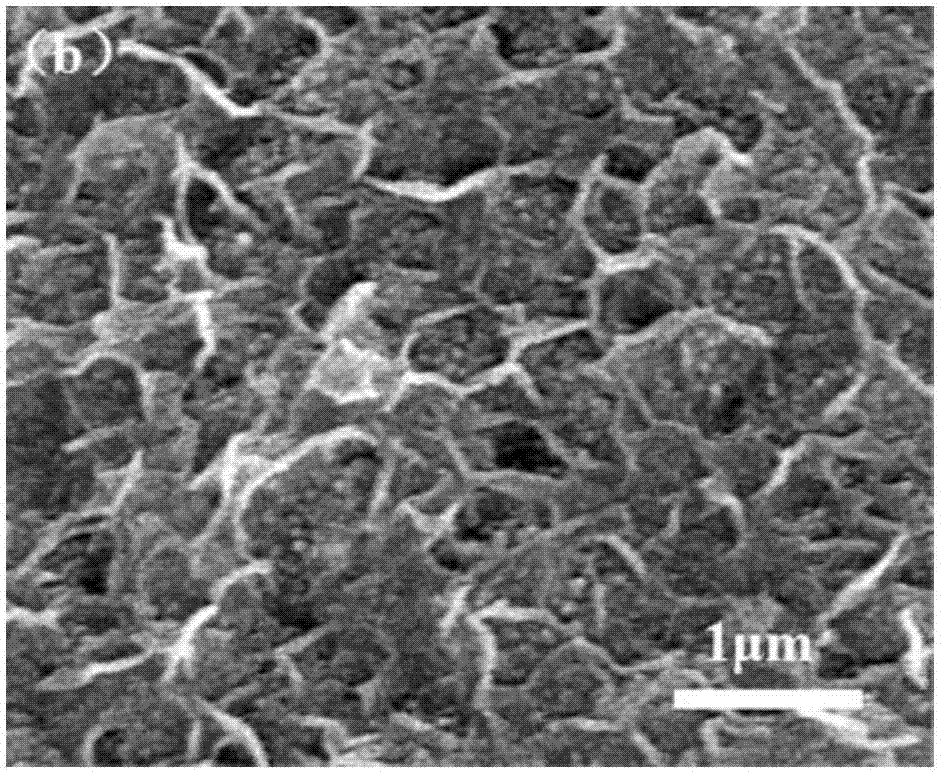

Embodiment 2

[0056] Other steps are as embodiment 1, only step (2) is changed into: the Ni(NO 3 ) 2 ·6H 2 O, 58mg of Co(NO 3 ) 2 ·6H 2 O and 120 mg of hexamethylenetetramine were mixed and dissolved in 30 mL of methanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com