Manganese cobalt oxide hollow microsphere material and preparation method

A hollow microsphere, manganese cobalt oxide technology, applied in nanotechnology, electrical components, electrochemical generators for materials and surface science, etc., can solve the problems of poor cycle performance and too fast capacity decay, and achieve simple equipment. , The process is simple, the effect of improving the morphology and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

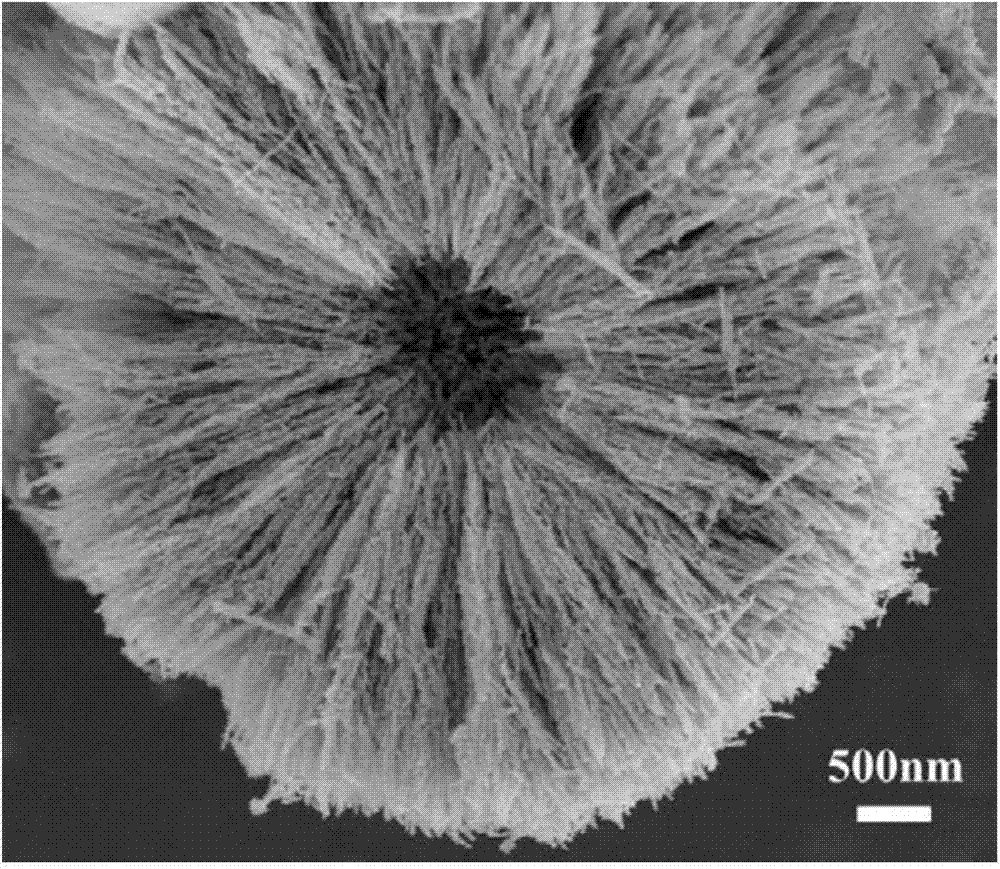

[0029] Add 0.002molMn(NO 3 ) 2 , 0.004Co(NO 3 ) 2 ·6H 2 Dissolve O in 12ml of deionized water, add 24ml of absolute ethanol, and mix well. Add 0.03 mol of urea, mix well, transfer the solution to a hydrothermal reactor, and heat at 90°C for 8 hours. After opening the kettle, the precipitate was centrifuged and washed several times with deionized water and alcohol, and then dried at 80°C. The precursor was placed in a muffle furnace at a heating rate of 1°C / min to 600°C, and then kept for 4 hours to calcinate to obtain hollow microsphere materials assembled from manganese cobaltate nanoneedles. The SEM photo of the prepared manganese cobaltate hollow microsphere material is as follows figure 1 It shows that the prepared product has a hollow structure and is assembled by nanoneedles. The diameter of the nanoneedles is small (≤30nm), the size is uniform, and the diameter of the hollow microspheres is on the micron level (≤6μm). At 200mAg -1 Test its performance under the current ...

Embodiment 2

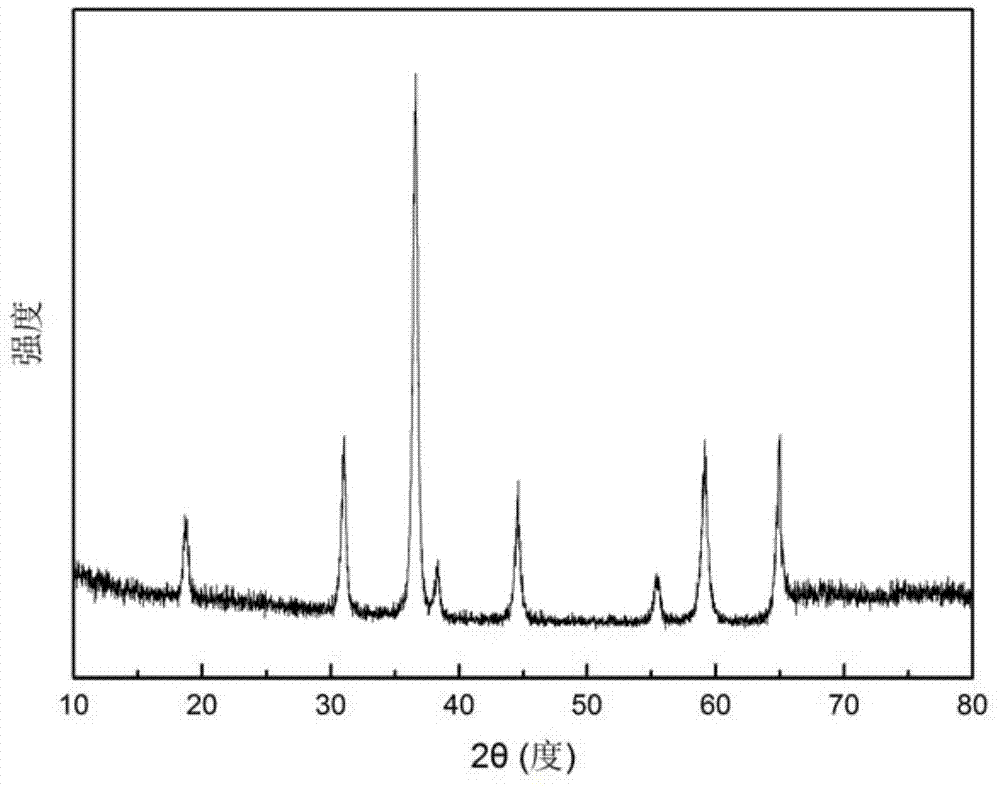

[0031] Add 0.002molMn(NO 3 ) 2 , 0.004Co(NO 3 ) 2 ·6H 2 Dissolve O in 18ml of deionized water, add 18ml of absolute ethanol, and mix well. Add 0.72mol of urea, mix well, transfer the solution to a hydrothermal reactor, and heat it at 110°C for 10h. After opening the kettle, the precipitate was centrifuged and washed several times with deionized water and alcohol, and then dried at 70°C. The precursor was placed in a muffle furnace at a heating rate of 2°C / min to 600°C, and then kept for 5 hours to calcinate to obtain a manganese cobaltate hollow microsphere material. The X-ray diffraction pattern of the prepared manganese cobaltate hollow microsphere material is as follows figure 2 It shows that the prepared product has a pure composition. At 100mAg -1 Test its performance under the current density of, the first discharge capacity can reach 1400mAhg -1 Above, its specific capacity can still reach 750mAhg after 25 cycles -1 the above.

Embodiment 3

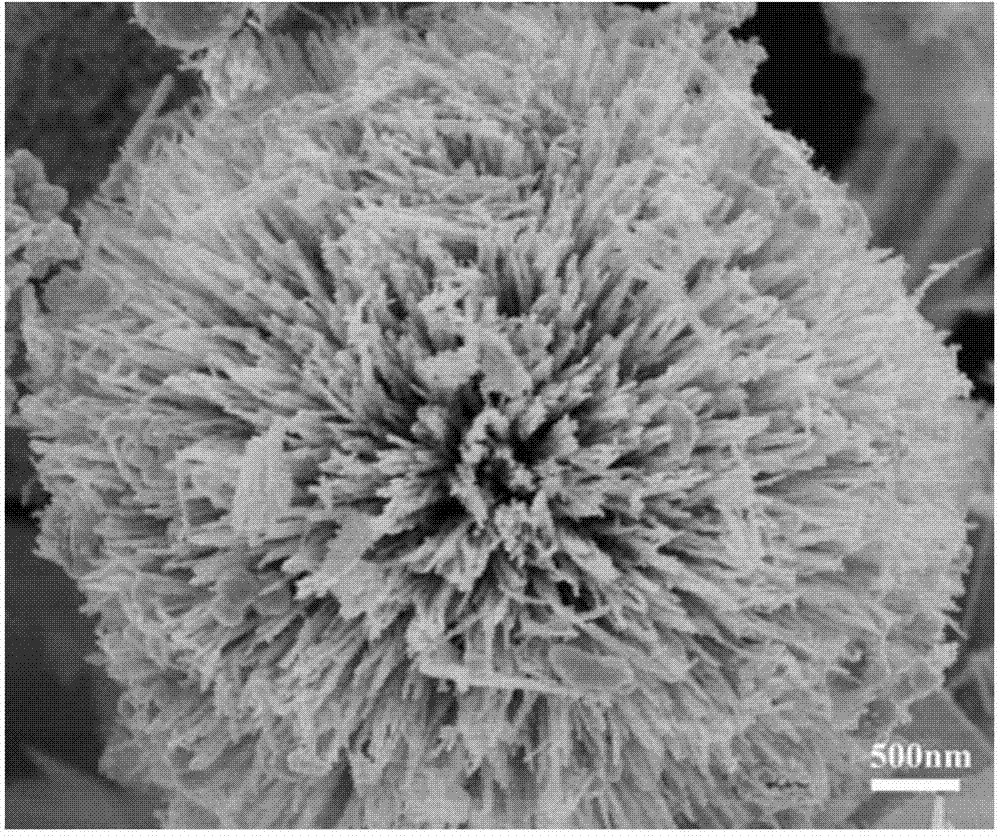

[0033] Add 0.002molMn(NO 3 ) 2 , 0.004Co(NO 3 ) 2 ·6H 2 Dissolve O in 24ml of deionized water, add 12ml of absolute ethanol, and mix well. Add 0.003mol of urea, mix well, transfer the solution to a hydrothermal reactor, and heat it at 130°C for 12h. After opening the kettle, the precipitate was centrifuged, washed several times with deionized water and alcohol, and then dried at 60°C. The precursor was placed in a muffle furnace at a heating rate of 3°C / min to 600°C, and then kept for 6 hours to calcinate to obtain a manganese cobaltate hollow microsphere material. The SEM photo of the prepared manganese cobaltate hollow microsphere material is as follows image 3 It shows that the prepared product is a hollow microsphere structure assembled by nanoneedles. The diameter of the nanoneedles is small (≤30nm), the size is uniform, and the diameter of the hollow microspheres is on the micron level (≤6μm). At 50mAg -1 Test its performance under the current density of, the first dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com