Preparation and photocatalytic application of Na4Ni3P4O15 photocatalyst

A technology of sodium nickel phosphate and photocatalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of efficient catalytic degradation, good photocatalytic activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: prepare Na 4 Ni 3 P 4 o 15

[0038] According to the chemical formula Na 4 Ni 3 P 4 o 15 The stoichiometric ratio of each element in, respectively weighed sodium carbonate Na 2 CO 3 : 0.848 g, nickel oxide NiO: 0.897 g, phosphorus pentoxide P 2 o 5 : 1.136 g, ground in an agate mortar and mixed evenly, then pre-calcined in a muffle furnace at 600°C for 5 hours in an air atmosphere, cooled naturally, and took out the sample; again the mixture was fully mixed and ground evenly, In the atmosphere, calcined at 1000°C for 6 hours, cooled to room temperature, taken out and fully ground to obtain Na 4 Ni 3 P 4 o 15 Photocatalyst powder.

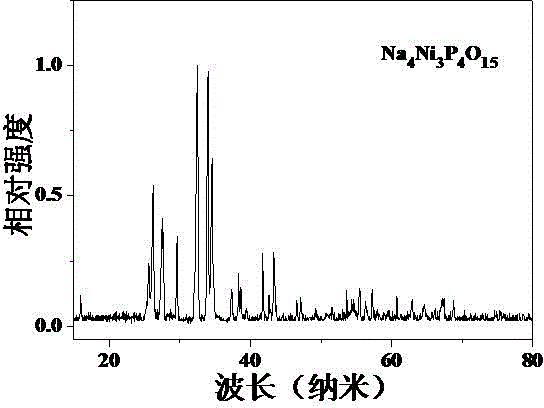

[0039] See attached figure 1 , it is the X-ray powder diffraction pattern of the sample prepared according to the technical scheme of this embodiment, and the XRD test result shows that the prepared sodium nickel phosphate Na 4 Ni 3 P 4 o 15 It is a single-phase material with good crystallinity;

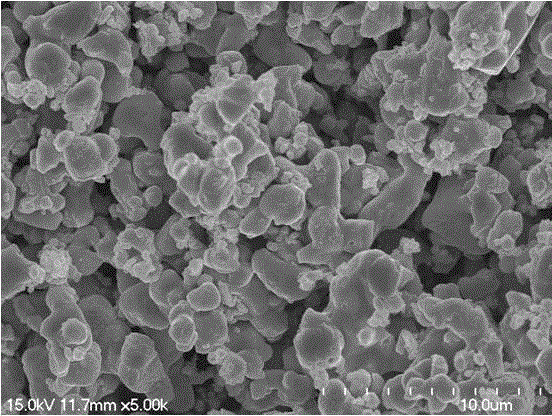

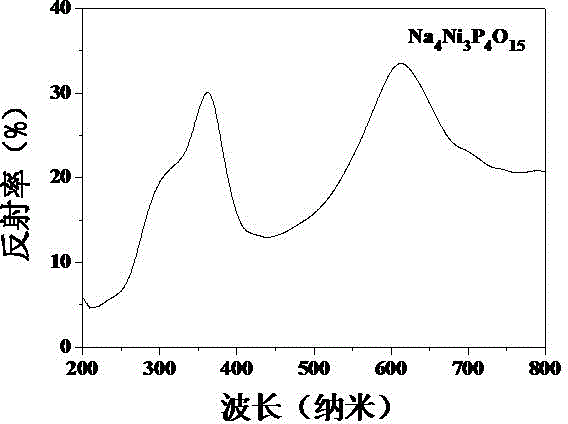

[0040] See...

Embodiment 2

[0045] Embodiment 2: prepare Na 4 Ni 3 P 4 o 15

[0046] According to the chemical formula Na 4 Ni 3 P 4 o 15 The stoichiometric ratio of each element in , respectively weighed sodium oxide Na 2 O: 0.496 g, basic nickel carbonate NiCO 3 2Ni(OH) 2 4H 2 O: 4.514 g, ammonium dihydrogen phosphate NH 4 h 2 PO 4 : 1.841 g, ground in an agate mortar and mixed evenly, then pre-calcined in an air atmosphere at 550°C for 8 hours in a muffle furnace, and after natural cooling, take out the sample; again fully mix the mixture and grind it evenly, in the air In the atmosphere, calcined at 950°C for 10 hours, cooled to room temperature, taken out and fully ground to obtain Na 4 Ni 3 P 4 o 15 Photocatalyst powder.

[0047] Its main structure, reflectance spectrum, concentration change for methylene blue degradation, kinetic curve and absorbance spectrum for methylene blue degradation are similar to those in Example 1.

Embodiment 3

[0048] Embodiment 3: prepare Na 4 Ni 3 P 4 o 15

[0049] According to the chemical formula Na 4 Ni 3 P 4 o 15 The stoichiometric ratio of each element in the formula, respectively weighed sodium bicarbonate NaHCO 3 : 1.344 g, nickel oxide Ni 2 o 3 : 0.992 g, phosphoric acid H 3 PO 4 : 1.568 g, ground in an agate mortar and mixed evenly, then pre-calcined in an air atmosphere at 400°C for 12 hours in a muffle furnace, cooled naturally, and took out the sample; again fully mixed the mixture and ground it evenly, in the air In the atmosphere, calcined at 850°C for 14 hours, cooled to room temperature, taken out and fully ground to obtain Na 4 Ni 3 P 4 o 15 Photocatalyst powder.

[0050] Its main structure, reflectance spectrum, concentration change for methylene blue degradation, kinetic curve and absorbance spectrum for methylene blue degradation are similar to those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com