Photocuring 3D printing silicon nitride ceramic precursor and preparation and forming method thereof

A technology of silicon nitride ceramics and ceramic precursors, which is applied in the field of additive manufacturing in mechanical manufacturing, can solve the problems of poor curing performance of precursors and affect development, and achieve good morphology and structure, good curing performance, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

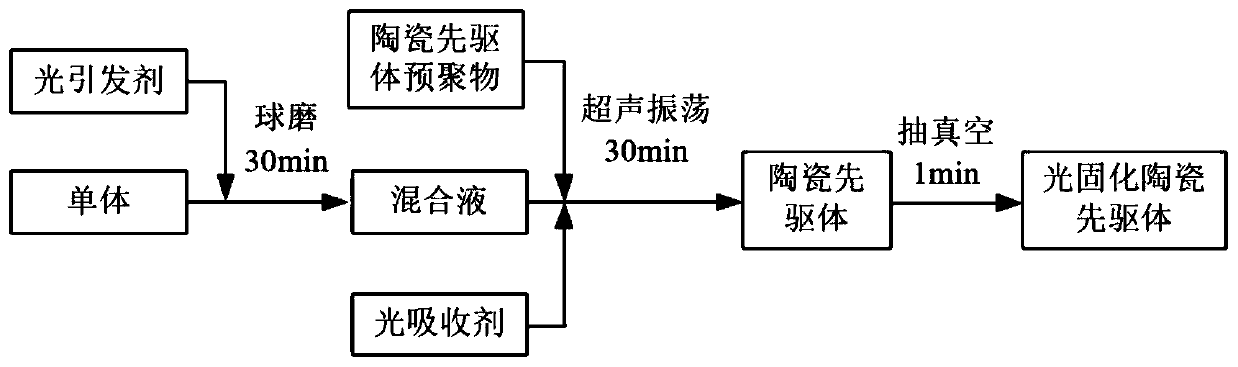

[0039] The preparation method of photocuring 3D printing silicon nitride ceramic precursor of the present invention comprises the following steps:

[0040] 1) Weighing the monomer and the photoinitiator, then placing the photoinitiator in the monomer, and ball milling for 30 minutes to obtain a mixed solution, wherein the speed of ball milling was 160r / min;

[0041] 2) Add a ceramic precursor prepolymer and a light absorber to the mixed solution obtained in step 1), ultrasonically oscillate for 30 minutes, and then vacuumize for 1 minute to obtain a photocurable 3D printing silicon nitride ceramic precursor.

[0042] The forming method of photocuring 3D printing silicon nitride ceramic precursor of the present invention comprises the following steps:

[0043] 1) Pour the light-curing 3D printing silicon nitride ceramic precursor into the slurry tank of the ceramic light-curing forming system, and use a coating scraper to scrape it;

[0044] 2) Move the workbench to the bottom...

Embodiment 1

[0050] The light-curing 3D printing silicon nitride ceramic precursor of the present invention is prepared from a monomer, a photoinitiator, a ceramic precursor prepolymer and a light absorber;

[0051] The monomer is 1,6 hexanediol diacrylate;

[0052] The ceramic precursor prepolymer is a polysilazane resin containing a methyl group;

[0053] The photoinitiator is 2,4,6-trimethylbenzoyl-diphenylphosphine oxide;

[0054] The light absorber is 2-(2-hydroxy-3.5-dibutyl-tert-phenyl)-5-chlorobenzotriazole;

[0055] The mass parts of monomer, photoinitiator, ceramic precursor prepolymer and light absorber are 40 parts, 0.1 parts, 60 parts and 0.2 parts respectively.

[0056] The preparation method of photocuring 3D printing silicon nitride ceramic precursor of the present invention comprises the following steps:

[0057] 1) Weighing the monomer and the photoinitiator, then placing the photoinitiator in the monomer, and ball milling for 30 minutes to obtain a mixed solution, whe...

Embodiment 2

[0067] The light-curing 3D printing silicon nitride ceramic precursor of the present invention is prepared from a monomer, a photoinitiator, a ceramic precursor prepolymer and a light absorber;

[0068] The monomer is isocyanoethyl methacrylate;

[0069] The ceramic precursor prepolymer is a polysilazane resin containing a vinyl group;

[0070] The photoinitiator is IRGACURE 819;

[0071] The light absorber is 2-(2-hydroxy-3.5-dibutyl-tert-phenyl)-5-chlorobenzotriazole;

[0072] The mass parts of monomer, photoinitiator, ceramic precursor prepolymer and light absorber are respectively 20 parts, 0.1 parts, 80 parts and 0.2 parts.

[0073] The preparation method of photocuring 3D printing silicon nitride ceramic precursor of the present invention comprises the following steps:

[0074] 1) Weighing the monomer and the photoinitiator, then placing the photoinitiator in the monomer, and ball milling for 30 minutes to obtain a mixed solution, wherein the speed of ball milling was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com