Novel luminescent composite material

A composite material and a new type of technology, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of hazards and limitations, and achieve the effects of avoiding concentration quenching, avoiding quenching, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

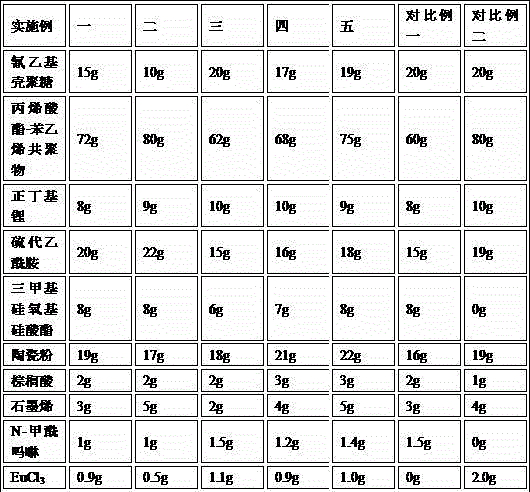

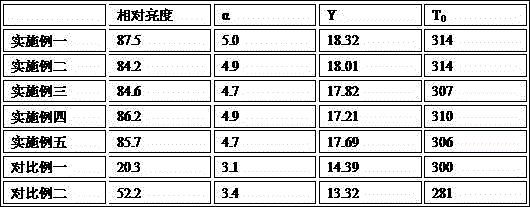

[0042] Mix 25g of silicon dioxide, 15g of ytterbium fluoride, 20g of boron oxide, 15g of rutile titanium dioxide, 10g of magnesium oxide, and 10g of shell powder, and then pass through a 500-mesh standard sieve to obtain a mixed powder; calcinate the mixed powder at 700°C 8 hours; then smelt the mixed powder at 1700°C for 3 hours, and quench to obtain a glass block; finally, after ball milling the glass block for 2 hours, pass through a 500-mesh standard sieve to obtain ceramic powder.

[0043] According to the mass composition of Table 1, the EuCl 3 and trimethylsiloxysilicate for 2 hours to obtain a mixture; add thioacetamide and ceramic powder to the mixture in turn, stir for 4 hours, then add palmitic acid and n-butyllithium, and stir for 2 hours at 80°C ; Then add cyanoethyl chitosan and graphene, stir at 120°C for 1 hour, finally add acrylate-styrene copolymer, N-formylmorpholine, and stir at 130°C for 4 hours to obtain a luminescent complex; Put the luminous composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com