Red fluorescent powder capable of being simultaneously effectively excited by near ultraviolet and blue LED light

A red phosphor and near-ultraviolet technology, applied in the field of red phosphor and its preparation, can solve the problems of the phosphor and the LED chip cannot accurately achieve the best effect, the half-peak width of the excitation spectrum is narrow, and the luminous efficiency is low, and the excitation wavelength can be achieved. Wide range, improve luminous brightness, good luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

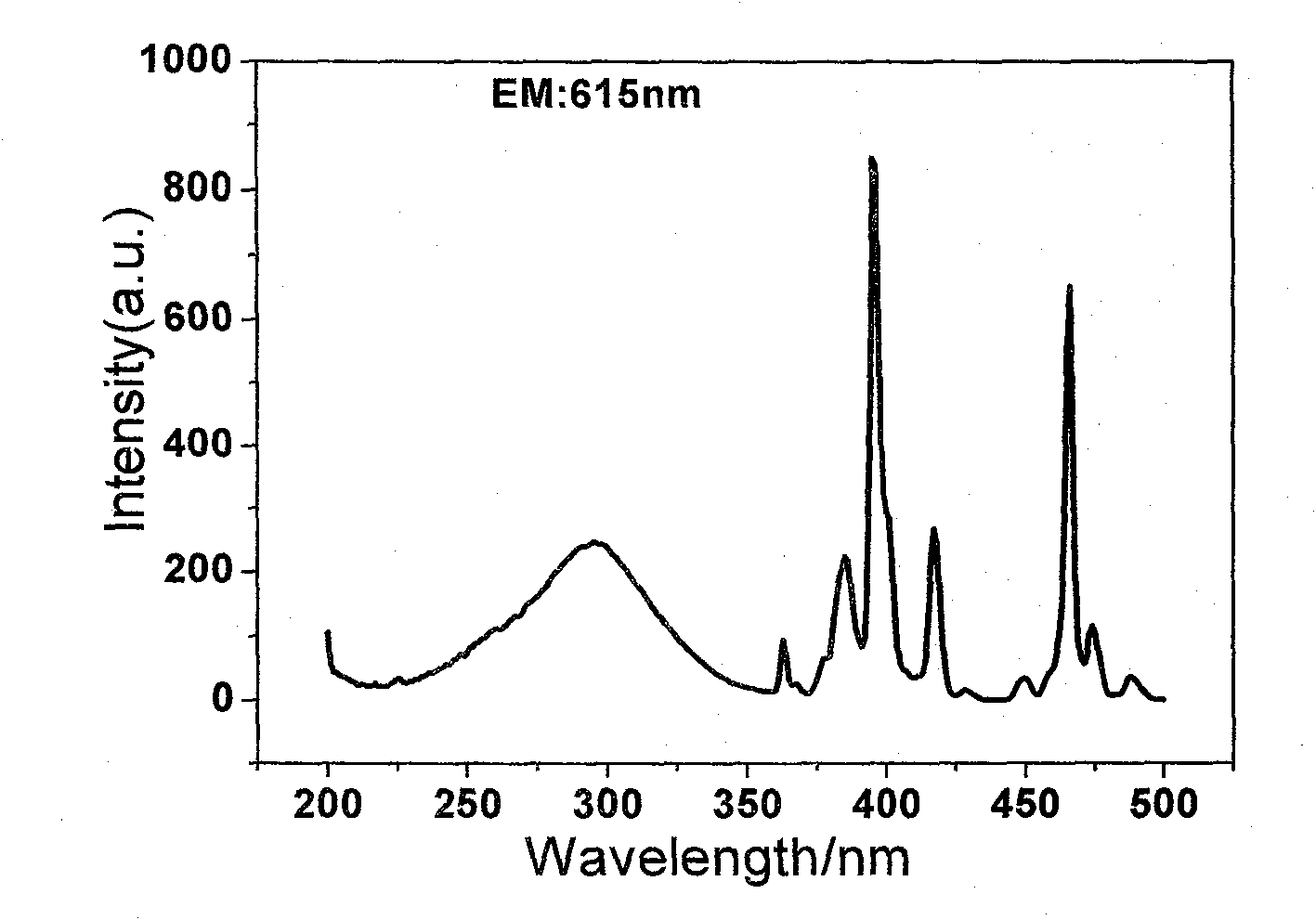

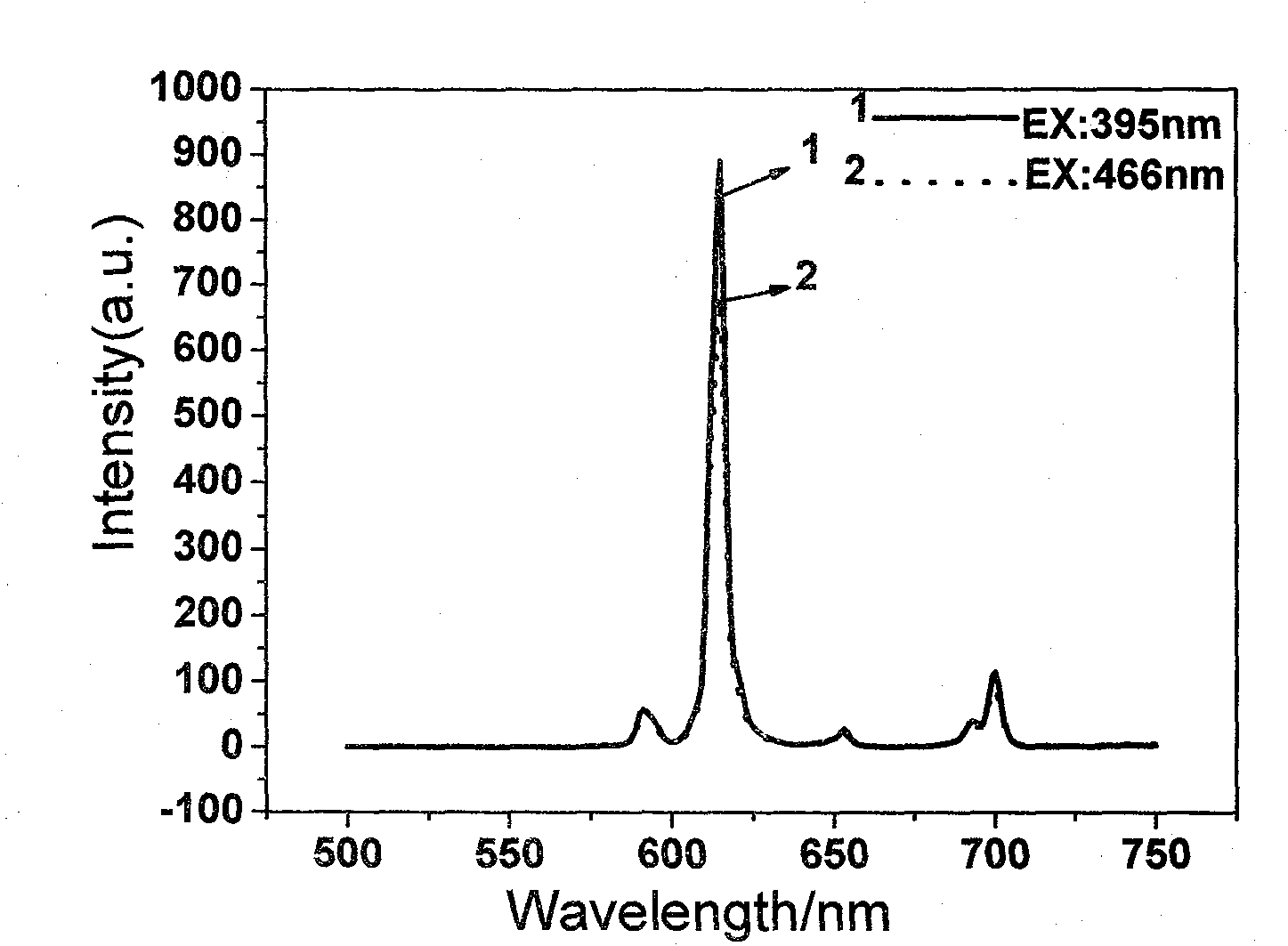

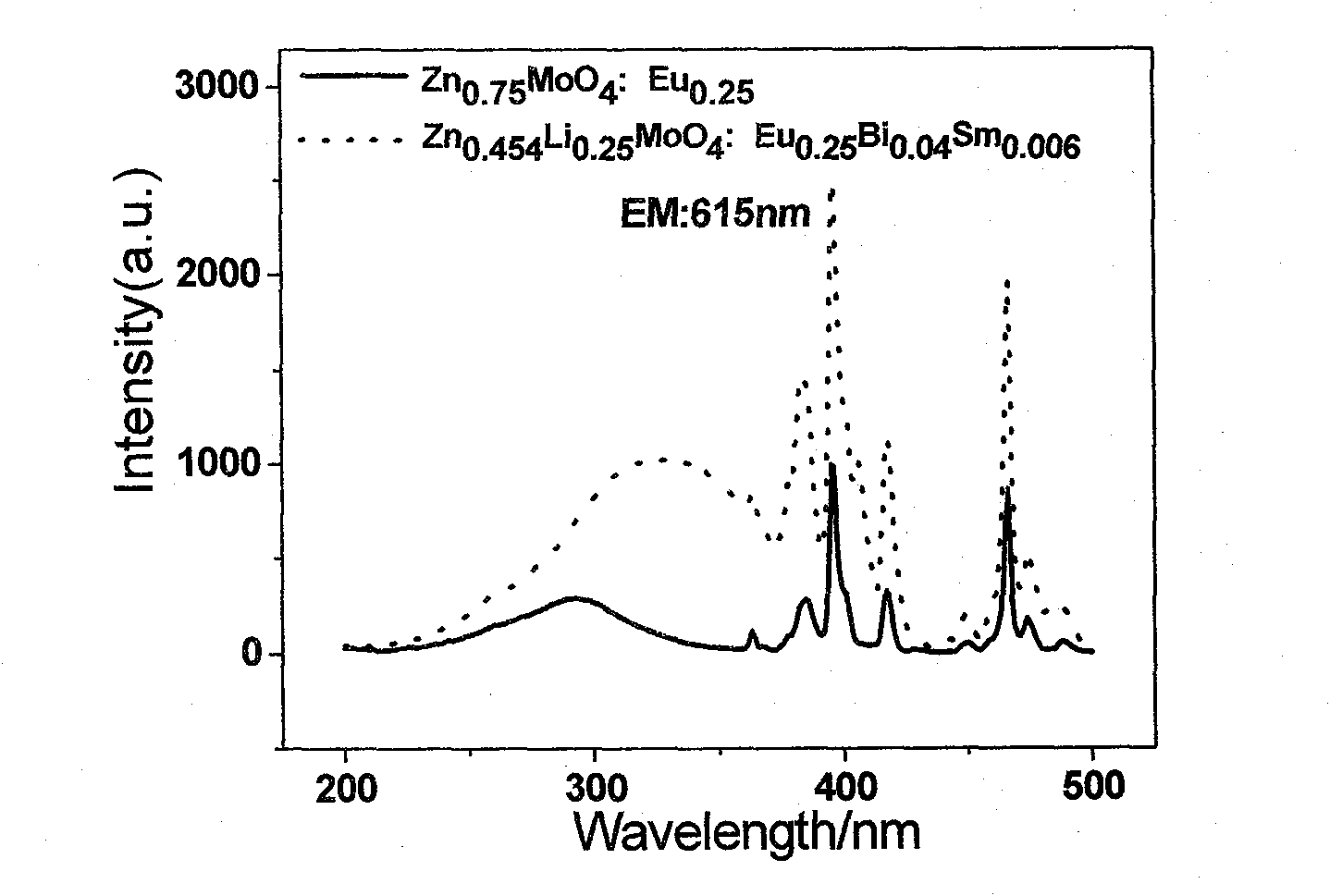

[0024] According to the molar ratio: Zn:Mo:Eu=0.75:1:0.25 weigh ZnO, MoO 3 , Eu 2 o 3 , the above raw materials are all analytically pure. After mixing the above raw materials evenly, put them into an alumina crucible and roast them in the air, and keep them at 850°C for 4 hours. Zn 0.75 MoO 4 :Eu 0.25 sample. Its excitation spectrum see figure 1 , the emission spectrum see figure 2 .

Embodiment 2

[0026] According to the molar ratio: Zn:Mo:Eu:Li=0.5:1:0.25:0.25 Weigh ZnO, MoO 3 , Eu 2 o 3 , LiCO 3 , the above raw materials are all analytically pure. After mixing the above raw materials evenly, put them into an alumina crucible and roast them in the air, and keep them at 800°C for 4 hours. Zn 0.5 Li 0.25 MoO 4 :Eu 0.25 sample.

Embodiment 3

[0028] According to the molar ratio: Zn:Mo:Eu:Li:Bi=0.46:1:0.25:0.25:0.04, weigh ZnO, MoO 3 , Eu 2 o 3 , LiCO 3 , Bi 2 o 3 , the above raw materials are all analytically pure. After mixing the above raw materials evenly, put them into an alumina crucible and roast them in the air, and keep them at 800°C for 4 hours. Zn 0.46 Li 0.25 MoO 4 :Eu 0.25 Bi 0.04 sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com